Lead-free silver conductive paste used for positive electrode of solar battery and preparation technique thereof

A technology for solar cells and front electrodes, applied in the direction of conductors, conductive materials dispersed in non-conductive inorganic materials, conductive materials, etc. Solve problems such as low slurry adhesion, achieve good contact, ensure fineness, and improve electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Accurately weigh 20g SiO2, 5g B2O3, 40g Bi2O3, 5g Al2O3, 10g TiO2, 20g ZnO six oxide powders, put them into an alumina crucible for melting, the melting temperature is 1400°C, and the holding time is 30min. Ball milling after water quenching, drying and sieving to obtain glass powder with a particle size of 5 μm;

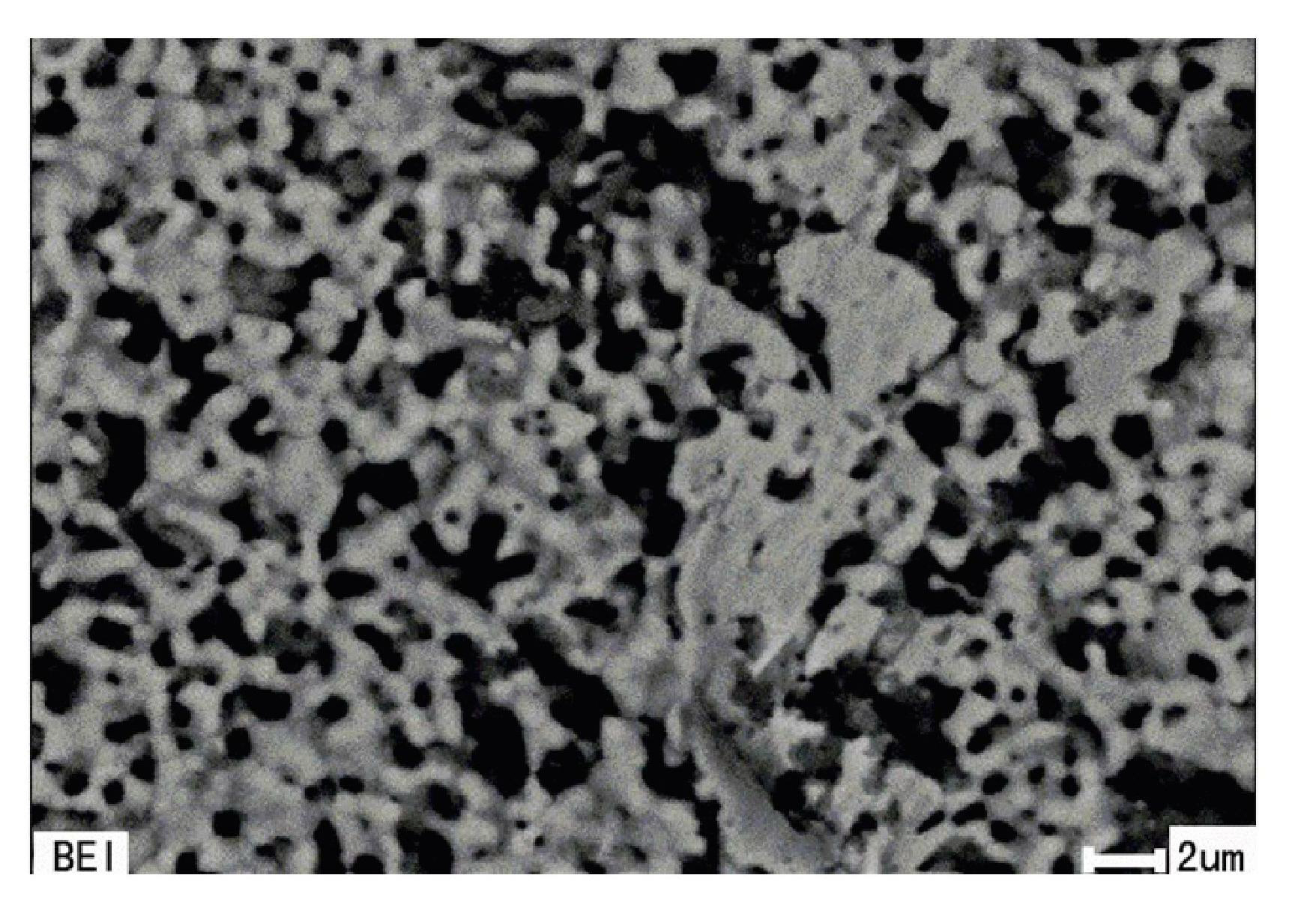

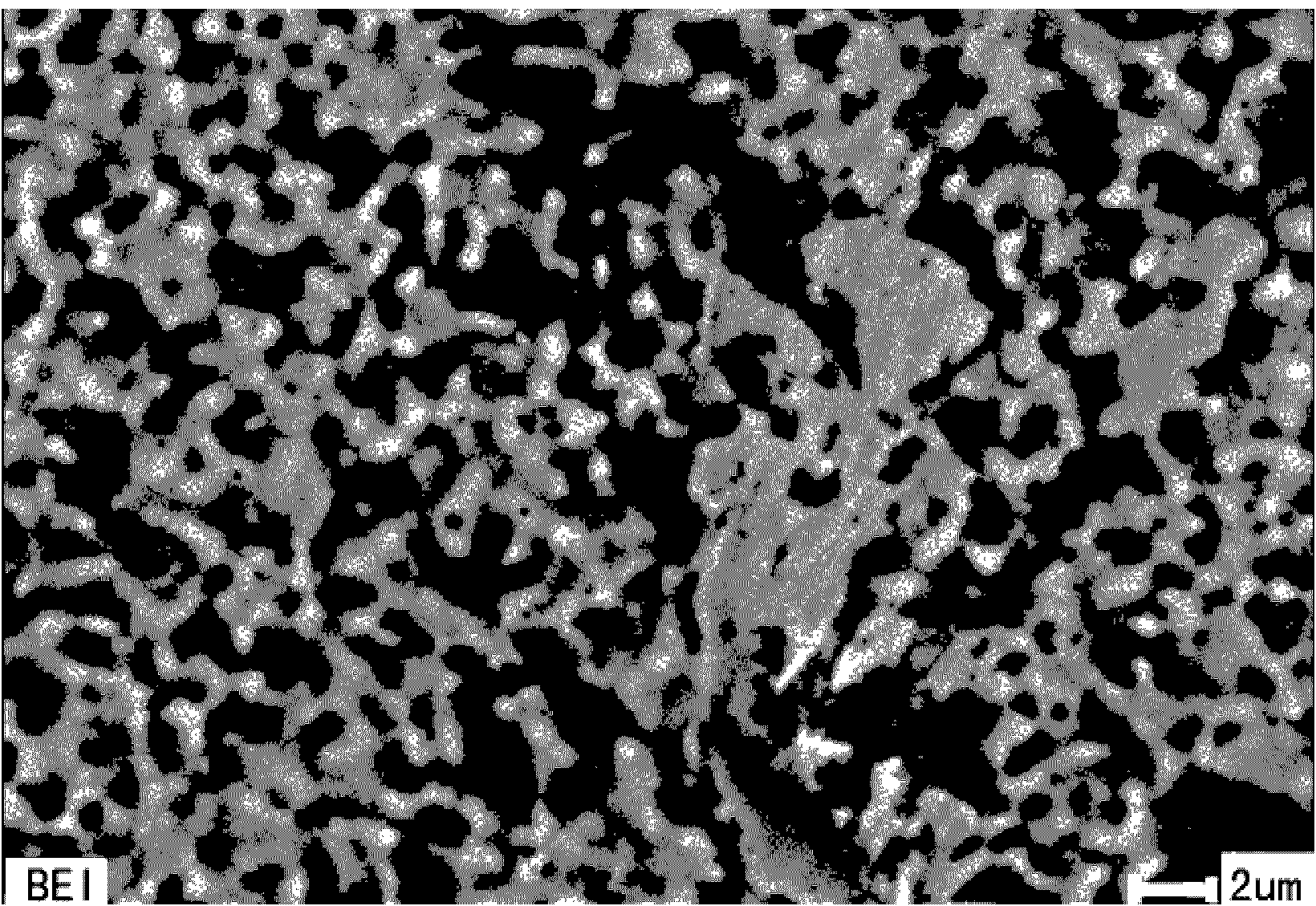

[0038] 2) Fully mix 82.7g of silver powder, 2g of glass powder, and 0.5g of zinc resinate in a mixer for 50 minutes, wherein the particle size D50 of silver powder is about 2 μm, and the particle size of zinc resinate is about 2 μm;

[0039] 3) Accurately weigh 15.3 g of organic solvent and various additives, mix them, and fully stir in a constant temperature water bath to form an organic carrier. The temperature of the water bath is 70°C, and the stirring time is 60 minutes;

[0040] 4) The mixed solid powder is mixed with the organic carrier, and fully ground with a three-roll mill to obtain the desired slurry.

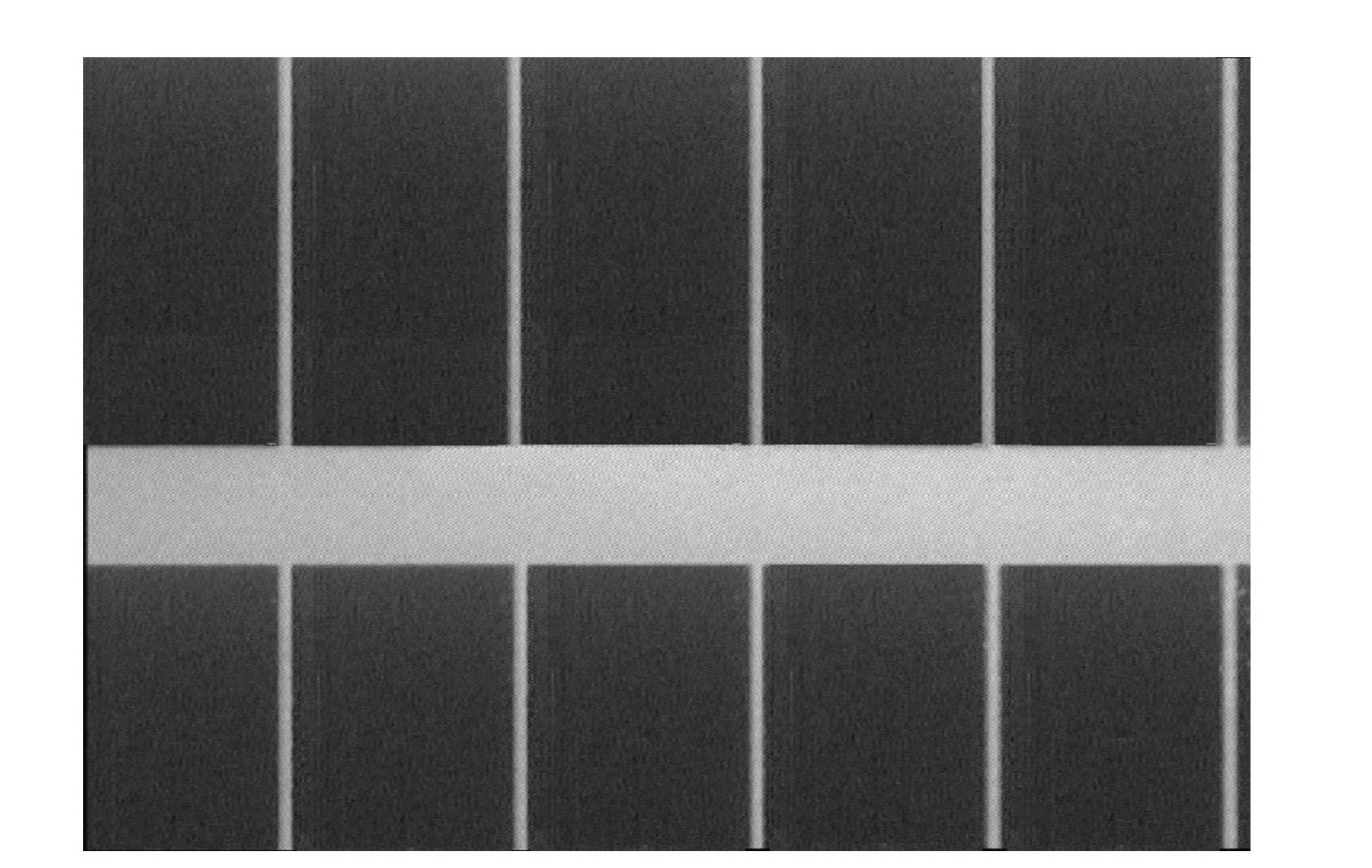

[0041] The resulting slurry was printed ...

Embodiment 2

[0043] 1) Accurately weigh 20g SiO2, 5g B2O3, 40g Bi2O3, 5g Al2O3, 10g TiO2, 20g ZnO six oxide powders, put them into an alumina crucible for melting, the melting temperature is 1400°C, and the holding time is 30min. Ball milling after water quenching, drying and sieving to obtain glass powder with a particle size of 5 μm;

[0044] 2) Fully mix 85g of silver powder, 3.0g of glass powder, and 0.8g of zinc resinate in a mixer for 50 minutes, wherein the particle size D50 of silver powder is about 1 μm, and the particle size of zinc resinate is about 1 μm;

[0045] 3) Accurately weigh 17g of organic solvent and various additives, mix them, and fully stir in a constant temperature water bath to form an organic carrier. The temperature of the water bath is 70°C, and the stirring time is 60 minutes;

[0046] 4) The mixed solid powder is mixed with an organic carrier, and fully ground with a three-roll mill to obtain the required slurry.

[0047] The resulting slurry was printed on ...

Embodiment 3

[0049] 1) Accurately weigh 20g SiO2, 5g B2O3, 40g Bi2O3, 5g Al2O3, 10g TiO2, 20g ZnO six oxide powders, put them into an alumina crucible for melting, the melting temperature is 1400°C, and the holding time is 30min. Ball milling after water quenching, drying and sieving to obtain glass powder with a particle size of 5 μm;

[0050] 2) Mix 85g of silver powder, 2.5g of glass powder, and 0.8g of zinc resinate in a mixer for 50 minutes, wherein the particle size D50 of silver powder is about 1 μm, and the particle size of zinc resinate is about 5 μm.

[0051] 3) Accurately weigh 17g of organic solvent and various additives, mix them, and fully stir in a constant temperature water bath to form an organic carrier. The temperature of the water bath is 70°C, and the stirring time is 60 minutes;

[0052] 4) The mixed solid powder is mixed with an organic carrier, and fully ground with a three-roll mill to obtain the desired slurry.

[0053] The resulting slurry was printed on a singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com