Method for preparing through-hole foam copper

A technology of foamed copper and electrolytic copper powder, applied in the field of metal manufacturing, to achieve uniform pore size and pore distribution, reduce scrap rate, and high sintering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The first step is to carry out decrystallization water treatment on commercially available NaCl particles, and use a standard sample sieve to sieve particles of different particle sizes;

[0031] In the second step, the NaCl particles with an average particle size of 0.2mm obtained from the first step of treatment and sieving are evenly mixed with commercially available electrolytic copper powder and ethanol, then loaded into a pressing mold, and unidirectionally pressurized to 250MPa to obtain a green body , the mass of the electrolytic copper powder and NaCl particles is given by m 铜 =V×(1-P)×8.96, m NaCl =V×P×2.16 is determined, wherein V is the volume of foamed copper, P is the porosity, and 8.96 and 2.16 are the densities of electrolytic copper and NaCl in a dense state respectively; the addition of ethanol is 2% of the total mass of electrolytic copper powder and NaCl %;

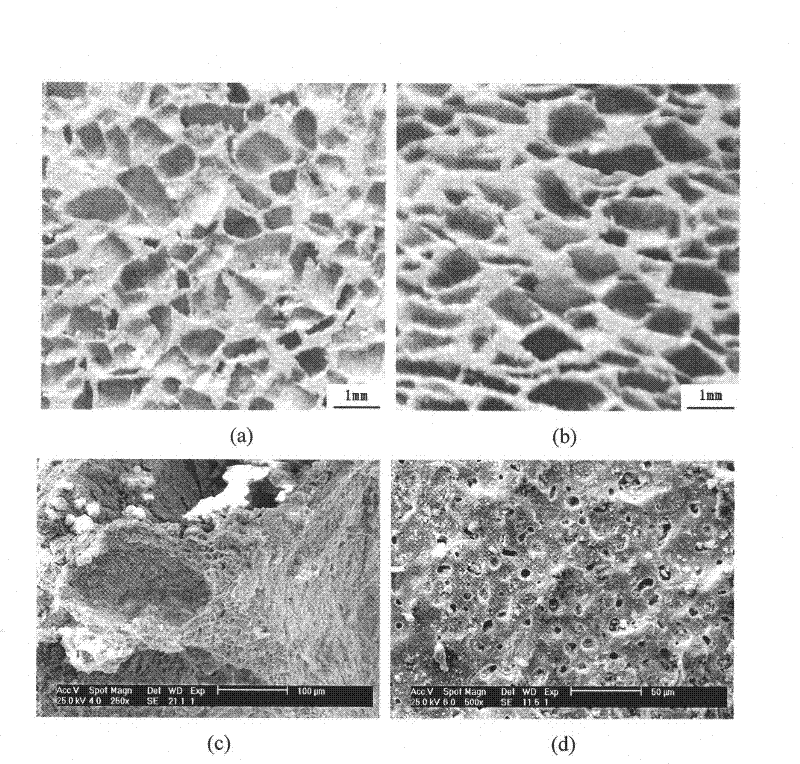

[0032] In the third step, the green body obtained in the second step is placed in an argon...

Embodiment 2

[0035] The first step is to carry out decrystallization water treatment on commercially available NaCl particles, and use a standard sample sieve to sieve particles of different particle sizes;

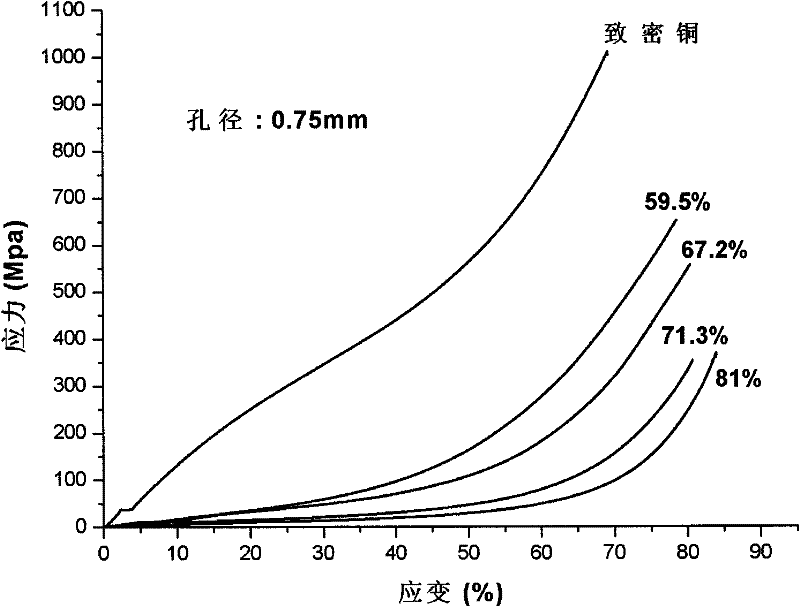

[0036]In the second step, the NaCl particles with an average particle size of 0.75mm obtained from the first step of treatment and sieving are evenly mixed with commercially available electrolytic copper powder and propanol, then loaded into a compression mold, and pressurized to 300MPa in one direction to obtain a raw material. billet, the mass of the electrolytic copper powder and NaCl particles is given by m 铜 =V×(1-P)×8.96, m NaCl =V×P×2.16 is determined, wherein V is the volume of foamed copper, P is the porosity, 8.96 and 2.16 are respectively the densities of electrolytic copper and NaCl in a dense state; the addition of propanol is the total mass of electrolytic copper powder and NaCl 3%;

[0037] In the third step, the green body obtained in the second step is placed in an ...

Embodiment 3

[0042] The first step is to carry out decrystallization water treatment on commercially available NaCl particles, and use a standard sample sieve to sieve particles of different particle sizes;

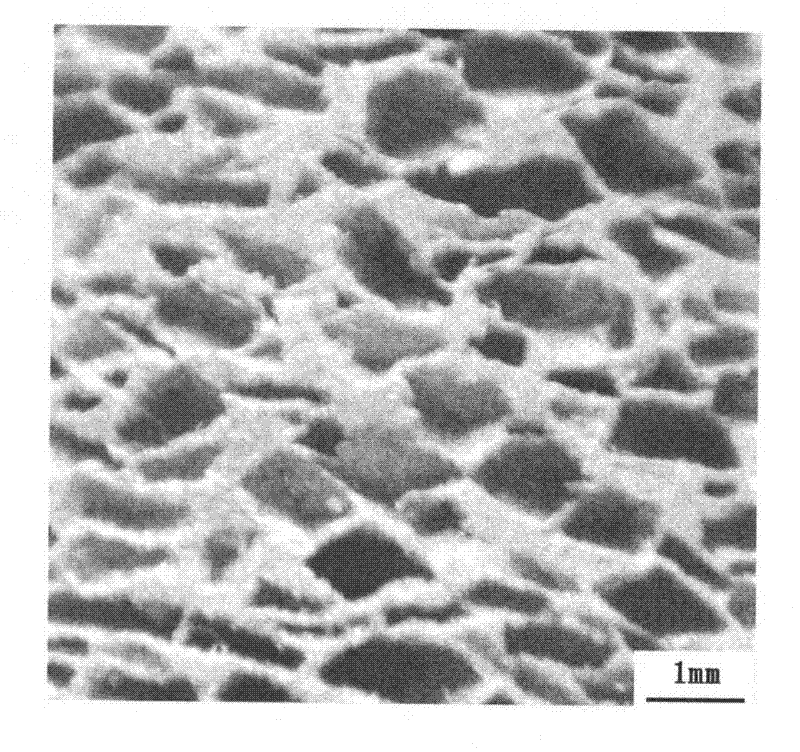

[0043] In the second step, the NaCl particles with an average particle size of 3mm obtained from the first step of treatment and sieving are evenly mixed with commercially available electrolytic copper powder and acetone, then loaded into a pressing mold, and unidirectionally pressurized to 300MPa to obtain a green body. The quality of described electrolytic copper powder and NaCl particle is by m 铜 =V×(1-P)×8.96, m NaCl =V × P × 2.16 is determined, wherein V is the volume of foamed copper, P is the porosity, 8.96 and 2.16 are respectively the densities of electrolytic copper and NaCl in a compact state; the addition of acetone is 4% of the total mass of electrolytic copper powder and NaCl %;

[0044] In the third step, the green body obtained in the second step is placed in an argo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com