Thin-wall anodic aluminum oxide film with large aperture and preparation method thereof

An anodized aluminum, large pore size technology, used in anodizing, electrolytic coatings, surface reaction electrolytic coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

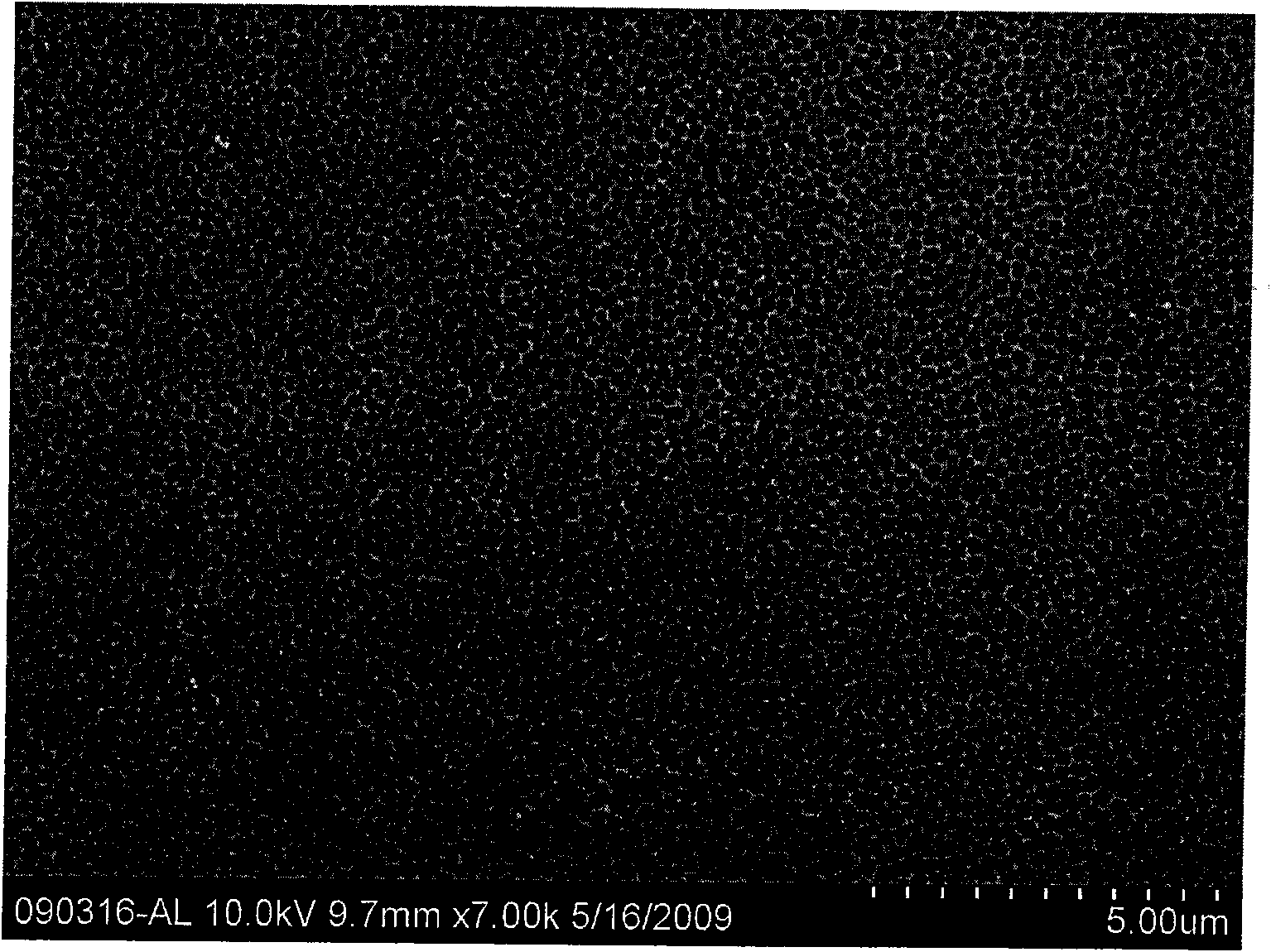

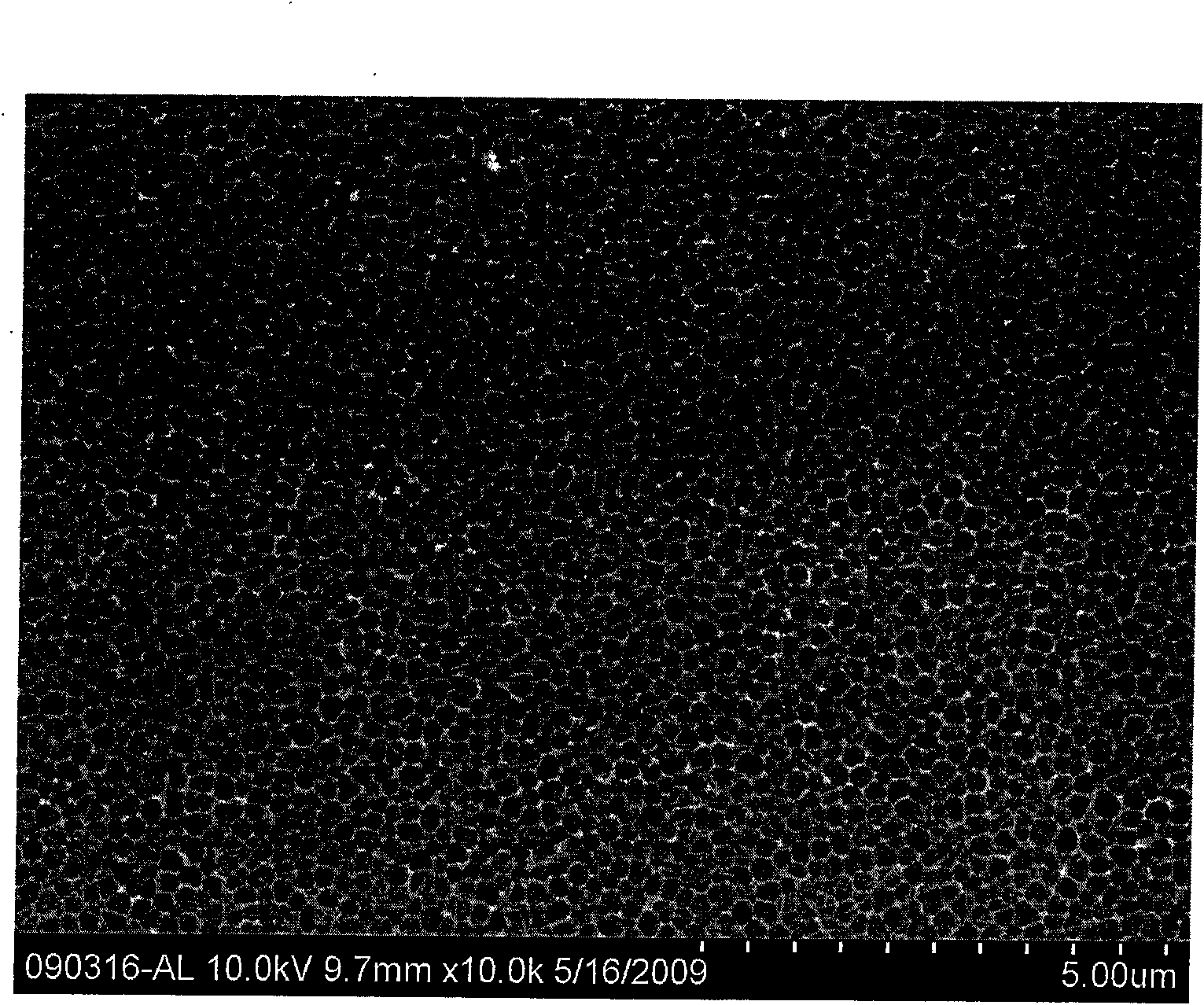

Image

Examples

Embodiment 1

[0022] The aluminum sheet is first ultrasonically cleaned with acetone, ethanol, and high-purity water for 10 minutes to remove surface grease and dirt. Anodic oxidation is carried out by putting the cleaned aluminum sheet into a mixed electrolyte with a mass percentage of phosphoric acid of 1% and a mass percentage of phosphoric acid and acetic acid of 1:1. The oxidation voltage was 40 volts, and the first anodizing time was 5 minutes. After taking out the aluminum sheet, clean it with high-purity water, then put the aluminum sheet in a mixed solution of 0.2mol / L chromic acid and 0.4mol / L phosphoric acid, and soak it at 60°C for 20 minutes; Under the same mixed electrolyte and anodic oxidation voltage conditions as the first step, the second anodic oxidation is carried out, and the anodic oxidation time is 10 hours; then the aluminum sheet is washed with high-purity water, and then placed in a phosphoric acid solution with a mass percentage of 10% Soak for 20 minutes.

[00...

Embodiment 2

[0025] The aluminum sheet is first ultrasonically cleaned with acetone, ethanol, and high-purity water for 10 minutes to remove grease and dirt on its surface. The cleaned aluminum sheet is put into a mixed electrolyte with a mass percentage of phosphoric acid of 1% and a mass percentage of phosphoric acid and acetic acid solution of 1:1 for anodic oxidation. The oxidation voltage is 80 volts, and the anodizing time for the first time is 3 minutes; after taking out the aluminum sheet, clean it with high-purity water, then put the aluminum sheet into a mixed solution of 0.2mol / L chromic acid and 0.4mol / L phosphoric acid. Soak at a temperature of 60°C for 20 minutes; then wash it with high-purity water, and then perform a second anodic oxidation under the same mixed electrolyte and anodic oxidation voltage conditions as the first step, and the anodic oxidation time is 1 hour; then use high-purity water to The aluminum sheet is washed clean, and then soaked in a 10% phosphoric ac...

Embodiment 3

[0029] The aluminum sheet is first ultrasonically cleaned with acetone, ethanol, and high-purity water for 10 minutes to remove surface grease and dirt; put the cleaned aluminum sheet into a solution with a mass percentage of 1% phosphoric acid and a 1:1 mass percentage of phosphoric acid and acetic acid solution. In the mixed electrolyte, anodic oxidation is carried out. The oxidation voltage is 160 volts, and the first anodic oxidation time is 1 minute; clean it with high-purity water, then put the aluminum sheet into a mixed solution of 0.2mol / L chromic acid and 0.4mol / L phosphoric acid, and soak it at 60°C 20 minutes; then wash it with high-purity water, and then perform the second anodic oxidation under the same mixed electrolyte and anodic oxidation voltage conditions as the first step, and the anodic oxidation time is 10 minutes; then wash the aluminum sheet with high-purity water, Then put it into a 10% phosphoric acid solution and soak for 20 minutes.

[0030] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com