Percolation efficiency of the conductivity of electrically conductive adhesives

A technology of conductive adhesive and conductive filler, applied in the field of conductive adhesive, which can solve the problems of high viscosity of conductive adhesive and increased contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1-Surface modification of conductive filler

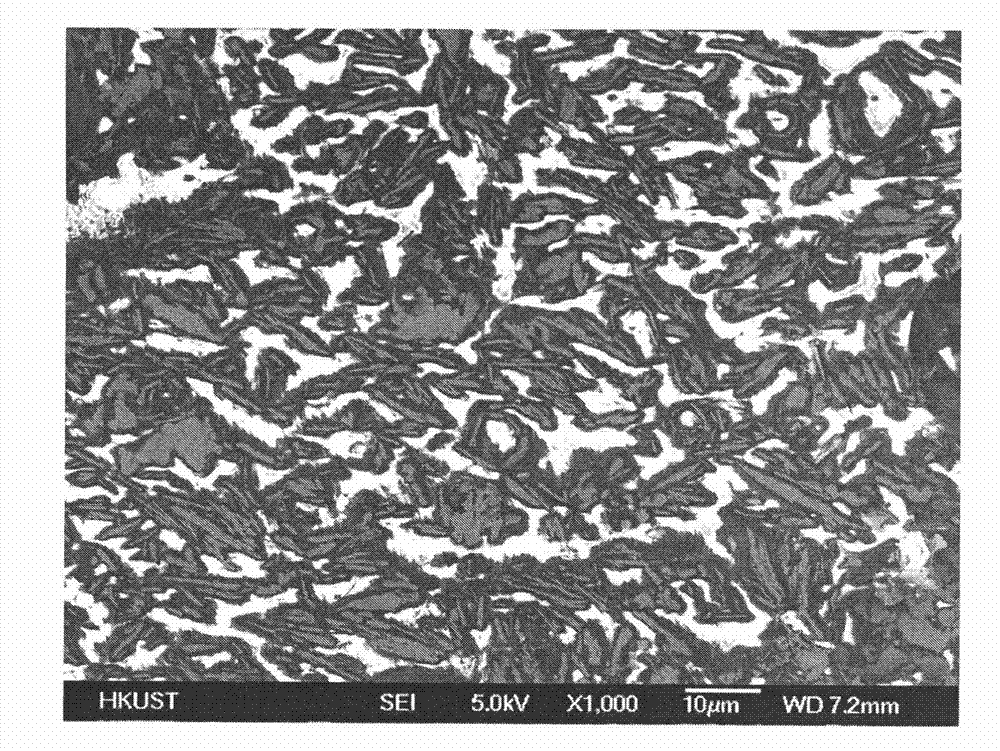

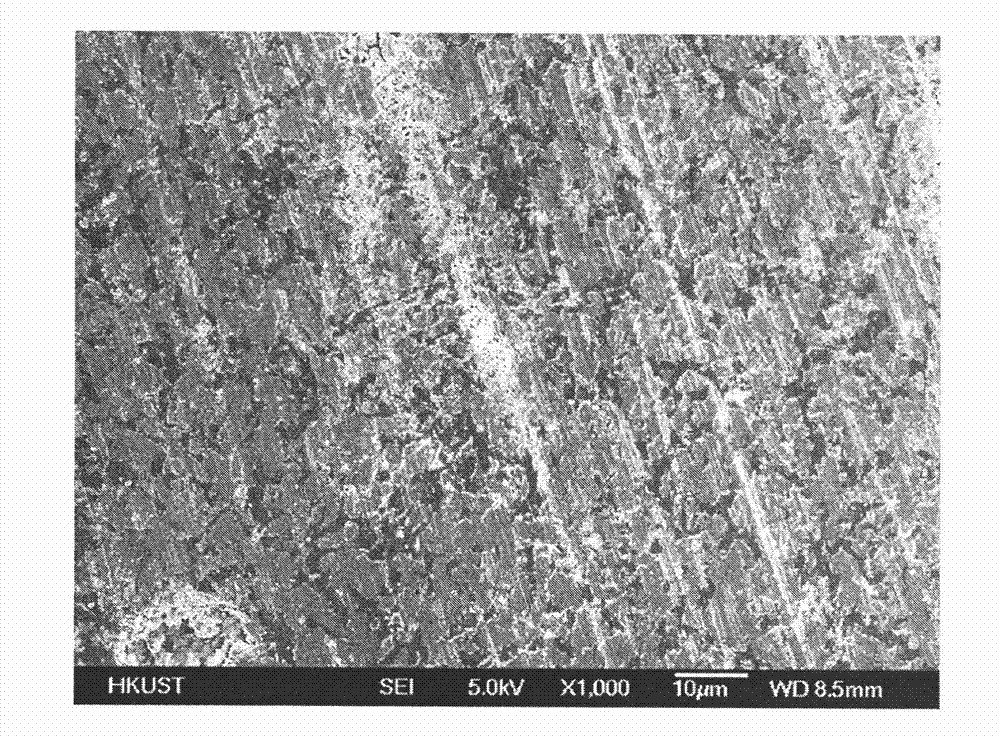

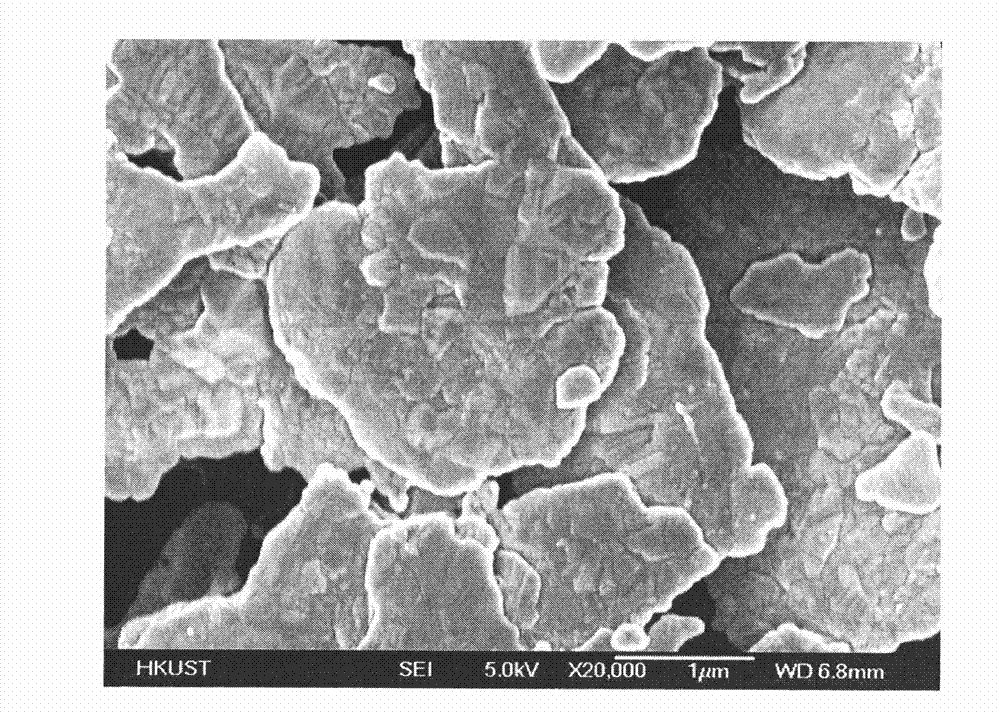

[0046] 10 grams of micron-sized silver flakes (about 5.6 microns in diameter) were dispersed in 100 ml of ethanol solution (containing 0.02% by weight of iodine). The solution was slowly stirred and mixed for 30 minutes at room temperature. The solution was then filtered through filter paper, and the filter cake was washed 3 times with ethanol. The filter cake was vacuum dried at room temperature until it was completely dry.

[0047] Preparation of modified conductive adhesive: The following data is based on a silver-containing adhesive formulation with a silver content of 75% by weight. In fact, the content of conductive filler can be in a wide range by adjusting the ratio of filler weight and resin matrix.

[0048] Mix 8.2 grams of dry silver flakes with 1.5 grams of bisphenol A epoxy resin under high-speed stirring

[0049] (EPON 828) and 1.3 grams of methyltetrahydrophthalic anhydride (MTHPA) were mixed for 30 minute...

Embodiment 2

[0051] Example 2-Sodium chlorite surface modifier

[0052] The modified conductive adhesive was prepared using the same steps as in Example 1, but the surface modifier was sodium chlorite instead of iodine. 10 grams of micron-sized silver flakes (about 5.6 microns in diameter) were dispersed in 100 ml of ethanol solution (containing 0.02% by weight of sodium chlorite). The solution was slowly stirred at room temperature for 30 minutes. The solution was filtered through filter paper and the filter cake was washed 3 times with ethanol. After that, the filter cake was vacuum dried at room temperature until it was completely dry.

Embodiment 3

[0053] Example 3-Bromine surface modifier

[0054] The modified conductive adhesive was prepared using the same steps as in Example 1, but the modifier was bromine instead of iodine. 10 grams of micron-sized silver flakes (about 5.6 microns in diameter) were dispersed in 100 ml of ethanol solution (containing 0.025% by weight of bromine). The solution was slowly stirred at room temperature for 30 minutes. The solution was filtered through filter paper and the filter cake was washed 3 times with ethanol. After that, the filter cake was vacuum dried at room temperature until it was completely dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com