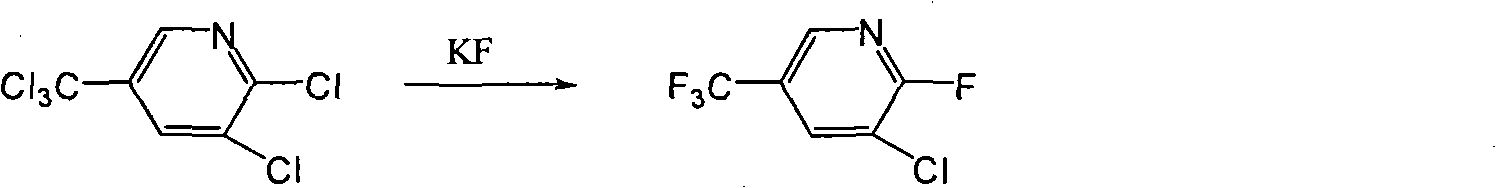

Novel method for synthesizing 2-fluoro-3-chloro-5-trifluoromethylpyridine

A technology for trifluoromethylpyridine and trichloromethylpyridine, which is applied in the field of synthesizing 2-fluoro-3-chloro-5-trifluoromethylpyridine, can solve the problems of unsatisfactory yield and general effect, and achieves Environmentally friendly, enhanced molecular activity, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 25g (0.43mol) of potassium fluoride, 50ml of toluene and 150ml of N, N-dimethylformamide were added to a 250ml four-necked reaction flask, and 0.66g (0.0029mol) of benzyltriethylammonium chloride was added as a phase transfer catalyst. Install the steam-water separator, heat to reflux at 115°C for reflux and dehydration for 3 hours, after the dehydration is completed, add 19.1g (0.072mol) of 2,3-dichloro-5-trichloromethylpyridine, and keep it warm at 120°C for 5 hours. After the end, filter with suction and discard the solid phase. The organic phase was decompressed and rectified to collect the effluent at 50-55°C / 11mmHg to obtain 2-fluoro-3-chloro-5-trifluoromethylpyridine with a purity of 98.5% and a yield of 94.7%.

Embodiment 2

[0024] Except that the reaction time was 6 hours, the ratio of potassium fluoride to 2,3-dichloro-5-trichloromethylpyridine added was 8:1, other reaction conditions and post-treatment methods were the same as in Example 1, and finally 2 -Fluoro-3-chloro-5-trifluoromethylpyridine, the purity reached 95.2%, and the yield was 92.1%.

Embodiment 3

[0026] Except that the reflux dehydration temperature was 90°C, other reaction conditions and post-treatment methods were the same as in Example 1, and finally 2-fluoro-3-chloro-5-trifluoromethylpyridine was obtained with a purity of 94.2% and a yield of 89% %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com