Preparation method for cyan coupler intermediate

A color coupler and intermediate technology, which is applied in the field of preparation of cyan coupler intermediates, can solve the problems of unfavorable production safety, high reaction conditions, and low product yield, and achieve the effect of simple and easy operation and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

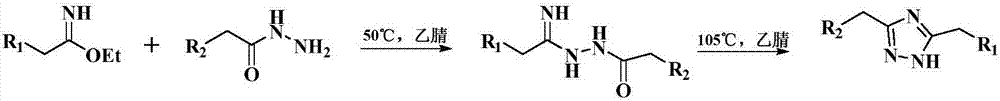

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, a kind of preparation method of cyan coupler intermediate, carries out following steps successively:

[0041] In a 500mL three-necked flask equipped with a thermometer, a condenser and a stirrer, 250mL of ethyl formate was added, and 38.4g of 4-tert-butylbenzohydrazide (purity ≥ 98%, 0.20mol) was added under mechanical stirring. After dissolving Add 41.34g of ethyl 3-ethoxy-3-iminopropionate (0.26mol), react at 50°C for 3h, cool to room temperature, filter and dry to obtain the transition intermediate 3-[2-(4-tert-butylphenyl Base)-hydrazino]-3-iminopropionic acid ethyl ester 54.90g (purity 99%), yield 90.0% (based on 4-tert-butylbenzohydrazide molar weight), melting point 144.2°C. Transfer to a 1L three-necked flask equipped with a thermometer, a condenser and a stirrer, add 500 mL of sodium carbonate (53.0 g, 0.5 mol) aqueous solution (pH 12.9), react at 75 ° C for 3 h, cool to room temperature and add dilute hydrochloric acid ( About 100mL) was neutral...

Embodiment 2

[0042] Embodiment 2, a kind of preparation method of cyan coupler intermediate, carries out following steps successively:

[0043]In a 500mL three-necked flask equipped with a thermometer, a condenser and a stirrer, 250mL of ethyl formate was added, and 38.4g of 4-tert-butylbenzohydrazide (purity ≥ 98%, 0.20mol) was added under mechanical stirring. After dissolving Add 34.98g of ethyl 3-ethoxy-3-iminopropionate (0.22mol), react at 50°C for 4h, cool to room temperature, filter and dry to obtain the transition intermediate 3-[2-(4-tert-butylphenyl Base)-hydrazino]-3-iminopropionic acid ethyl ester 56.12g (99% purity), yield 92.0% (based on 4-tert-butylbenzohydrazide molar weight), melting point 144.5°C. Transfer to a 1L three-neck flask equipped with a thermometer, condenser and stirrer, add 500mL of sodium carbonate (53.0g) aqueous solution, react at 80°C for 3h, cool to room temperature and add dilute hydrochloric acid (about 100mL) dropwise to neutralize to pH 7 The target p...

Embodiment 3

[0044] Embodiment 3, a kind of preparation method of cyan coupler intermediate, carries out following steps successively:

[0045] In a 500mL three-necked flask equipped with a thermometer, a condenser and a stirrer, 250mL of ethyl acetate was added, and 38.4g of 4-tert-butylbenzohydrazide (purity ≥ 98%, 0.20mol) was added under mechanical stirring. After dissolving Add 34.98g of ethyl 3-ethoxy-3-iminopropionate (0.22mol), react at 60°C for 3h, cool to room temperature, filter and dry to obtain the transition intermediate 3-[2-(4-tert-butylphenyl Base)-hydrazino]-3-iminopropionic acid ethyl ester 57.65g (99% purity), yield 94.5% (based on 4-tert-butylbenzohydrazide molar weight), melting point 144.0°C. Transfer to a 1L three-neck flask equipped with a thermometer, condenser and stirrer, add 500mL of sodium carbonate (53.0g) aqueous solution, react at 80°C for 3h, cool to room temperature and add dilute hydrochloric acid (about 100mL) dropwise to neutralize to pH 7 The target ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com