Recombination current driven nine-phase plane motor, linear-rotating motor and driver thereof

A compound current and rotating motor technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of low winding utilization, low system efficiency, low thrust density, etc., and achieve good dynamic characteristics, large plane motion range, The effect of high thrust density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

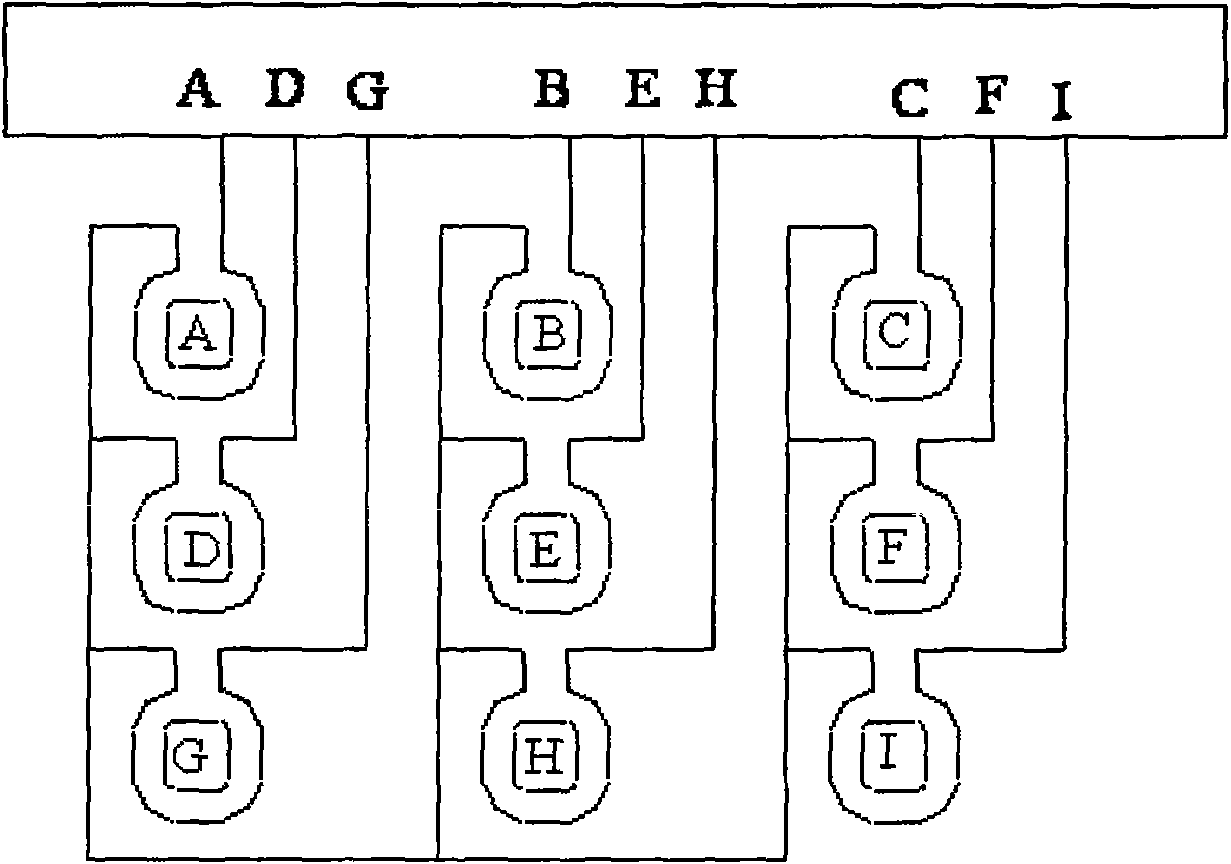

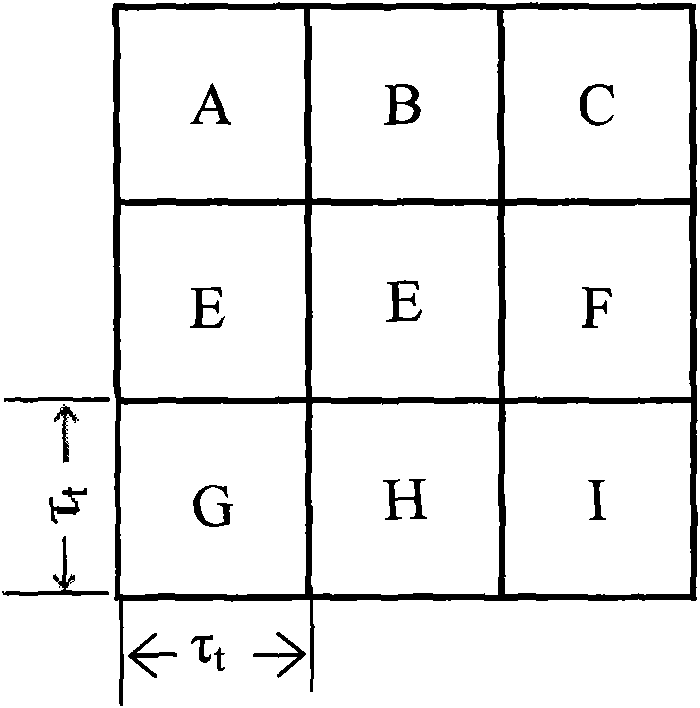

specific Embodiment approach 1

[0035] Embodiment 1: The composite current-driven nine-phase planar motor described in this embodiment includes an armature component and a permanent magnet excitation component. There is an air gap between the armature component and the permanent magnet excitation component, wherein the armature component includes an armature winding and the armature core; the permanent magnet excitation part includes the permanent magnet array and the permanent magnet yoke plate; the coil distance τ in the armature part t The pole distance τ of the permanent magnet array in the permanent magnet excitation part p Satisfy the relation 3nτ t =(3n±1)τ p , the planar motor is composed of i unit motors, each unit motor includes 9 coils and 2 permanent magnets, the 9 coils form a 3×3 matrix, and each coil is a phase armature winding, a total of There are 9 phase armature windings, which are represented as; A phase, B phase, C phase, D phase, E phase, F phase, G phase, H phase, I phase armature wi...

specific Embodiment approach 2

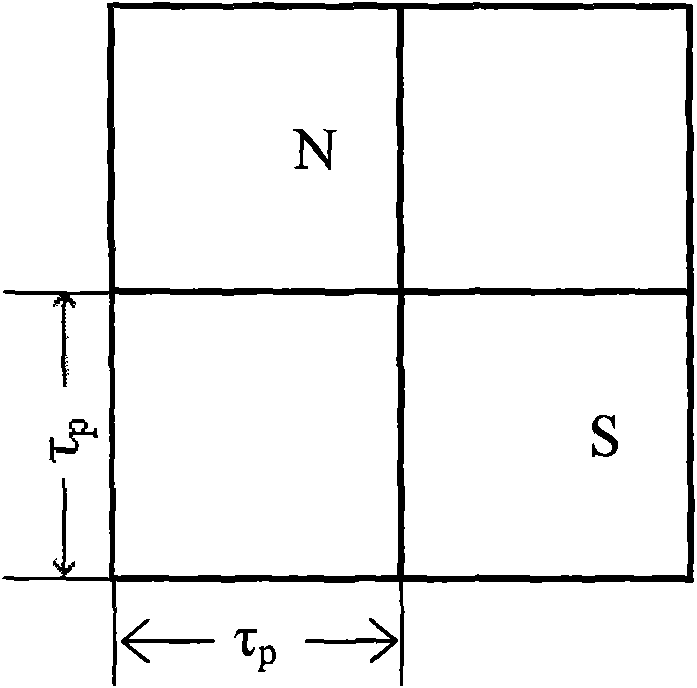

[0037] Specific Embodiment 2: The composite current-driven nine-phase planar motor described in this embodiment includes an armature component and a permanent magnet excitation component. There is an air gap between the armature component and the permanent magnet excitation component, wherein the armature component includes an armature winding and the armature core; the permanent magnet excitation part includes the permanent magnet array and the permanent magnet yoke plate; the coil distance τ in the armature part t The pole distance τ of the permanent magnet array in the permanent magnet excitation part p Satisfy the relation 3nτ t =(3n±1)τ p , each planar motor is composed of i unit motors, each unit motor includes S coils and P permanent magnets, the P=2h 2 , S=9(m 2 +1) / 2; the flat permanent magnet yoke plate in each unit motor is evenly divided into 2h×2h permanent magnet cells, and the side length of the permanent magnet cells is the permanent magnet array pole pitch ...

specific Embodiment approach 3

[0042] Specific implementation mode three: see Figure 4 , Figure 5 This embodiment will be described. This embodiment is an embodiment of the composite current-driven nine-phase planar motor described in the second embodiment. This embodiment is composed of a motor unit, wherein m=3, h=4, n=3, and the motor has S=45 coils and P=32 permanent magnets, the coil distance τ in the armature part t The pole distance τ of the permanent magnet array in the permanent magnet excitation part p Satisfy the relation 9τ t =8τ p . see Figure 5 , since 3m and 2h are 9 and 8 respectively, which are coprime numbers, the flat permanent magnet yoke plate is evenly divided into 2h×2h permanent magnet unit cells, that is, 8×8 permanent magnet unit cells, and the 32 permanent magnets They are respectively fixed in the diagonally adjacent permanent magnet cells on the permanent magnet yoke plate, the permanent magnets are parallel or vertically non-adjacent, and the permanent magnets in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com