Production technology of building sheets and building sheets using same and application thereof

A production process and building board technology, which is applied in construction, building structure, abrasives, etc., can solve the problems of complex production process, low production efficiency and high production cost of building board materials, and achieve a wide range of use, high production efficiency, and high production efficiency. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

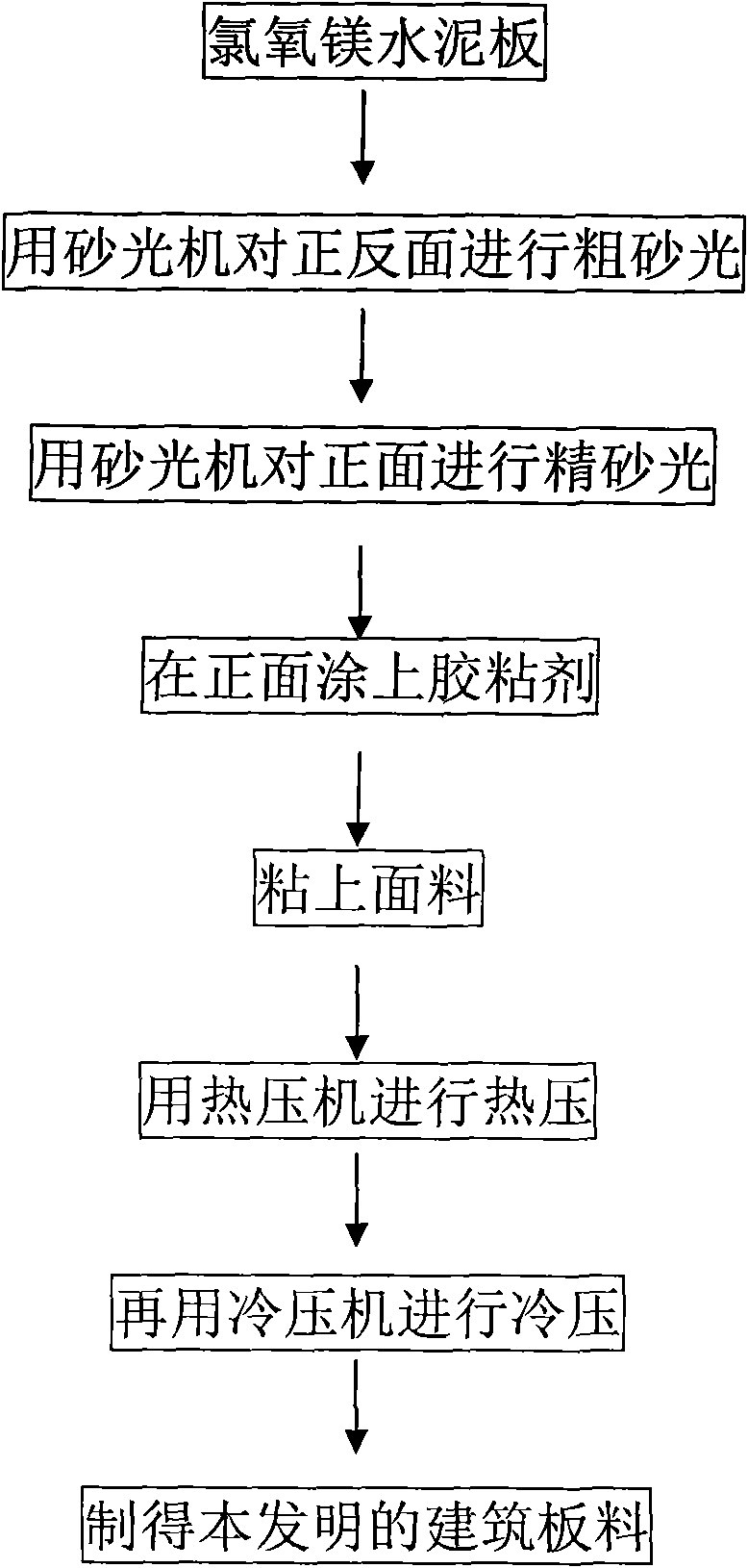

[0021] Such as figure 1 Shown, a kind of production technology of building panel comprises the following steps:

[0022] (1), using the magnesium oxychloride cement board as the base material, use a sander to carry out coarse sanding on the front and back of the magnesium oxychloride cement board, and the grain size number of the coarse sand belt of the sander is 20#-60#;

[0023] (2) Use a sander to finely sand the front of the magnesium oxychloride cement board. The grain size of the fine sand belt of the sander is 80#-200#, and the positive and negative deviation of the front after fine sanding is 0.02 mm-0.5mm (the board surface has no obvious unevenness);

[0024] (3), apply adhesive on the front side, stick the fabric, carry out hot pressing with a hot press, and then carry out cold pressing with a cold press to obtain the building board of the present invention.

[0025] According to actual production needs, the gluing process of the step (3) is machine-coated with a ...

Embodiment 2

[0029] Another production process for building panels, comprising the following steps:

[0030] (1), using the magnesium oxychloride cement board as the base material, use a sander to carry out coarse sanding on the front and back of the magnesium oxychloride cement board, and the grain size number of the coarse sand belt of the sander is 20#-60#;

[0031] (2) Use a sander to finely sand the front of the magnesium oxychloride cement board. The grain size of the fine sand belt of the sander is 80#-200#, and the positive and negative deviation of the front after fine sanding is 0.02 mm-0.5mm (the board surface has no obvious unevenness);

[0032] (3) Apply polyurethane styrofoam on the front, the amount of glue applied is 20g-300g / m 2 , glued to the wood, and hot pressed with a hot press, the hot pressing pressure is 1Kg-25Kg / cm 2 , the hot pressing time is 4-15 minutes, and then cold pressing with a cold press, the cold pressing pressure is 1Kg-25Kg / cm 2 , cold pressing time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com