Starch base degradable plastic

A technology for degrading plastics and starch-based plastics, applied in the field of starch-based degradable plastics, can solve problems such as poor solubility, and achieve the effects of low cost, wide sources and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 10 grams of cornstarch into a two-necked flask equipped with a thermometer, add 100mL of distilled water, heat up to 85°C, gelatinize the cornstarch for 30 minutes, then lower the temperature to 45°C, add 2g of butyl acrylate, 5% Potassium permanganate solution and 10ml of absolute ethanol, and finally 10% oxalic acid was added dropwise until colorless, the reaction was complete, vacuum filtration under reduced pressure, and the grafted crude product was obtained. In a high-speed mixer, mix and stir 2 grams of polyvinyl alcohol, 1.5 grams of glycerin and 1 gram of glyoxal, heat it up to 110-140 ° C, keep it for 5-20 minutes, add starch grafted crude product and initiator peroxidation After 0.03 g of dibenzoyl, heat up to 160-200° C. and keep for 20-40 minutes to obtain a starch-based degradable plastic.

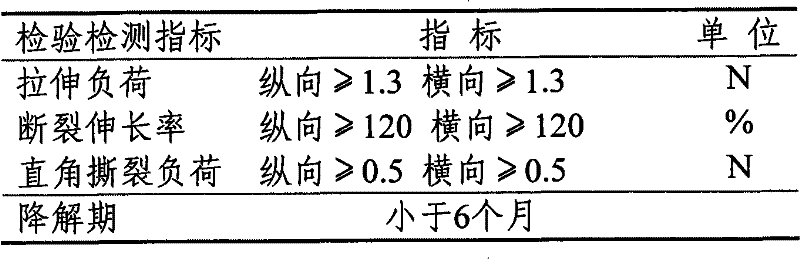

[0025] Product performance index

[0026] The product formula of Example 1 was used to obtain the prototype product of agricultural degradable starch film, and ...

Embodiment 2

[0030] Starch 80

[0031] Polyvinyl alcohol 12

[0032] Butyl acrylate 10

[0033] Pentylene glycol 10

[0034] Butyraldehyde 8

[0035] Cumyl peroxide 0.4

[0036] According to the above formula, the starch-based degradable plastic was prepared with reference to the preparation method of Example 1.

Embodiment 3

[0038] Starch 60

[0039] Polyvinyl alcohol 6

[0040] Butyl acrylate 10

[0041] Diethylene glycol 8

[0042] Propionaldehyde 5

[0043] Azobisisobutyronitrile 0.2

[0044] According to the above formula, the starch-based degradable plastic was prepared with reference to the preparation method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com