Electro-catalytic membrane reactor device

An electrocatalytic membrane and reactor technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor stability, anode dissolution, secondary pollution operation stability, etc. High efficiency and improved electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

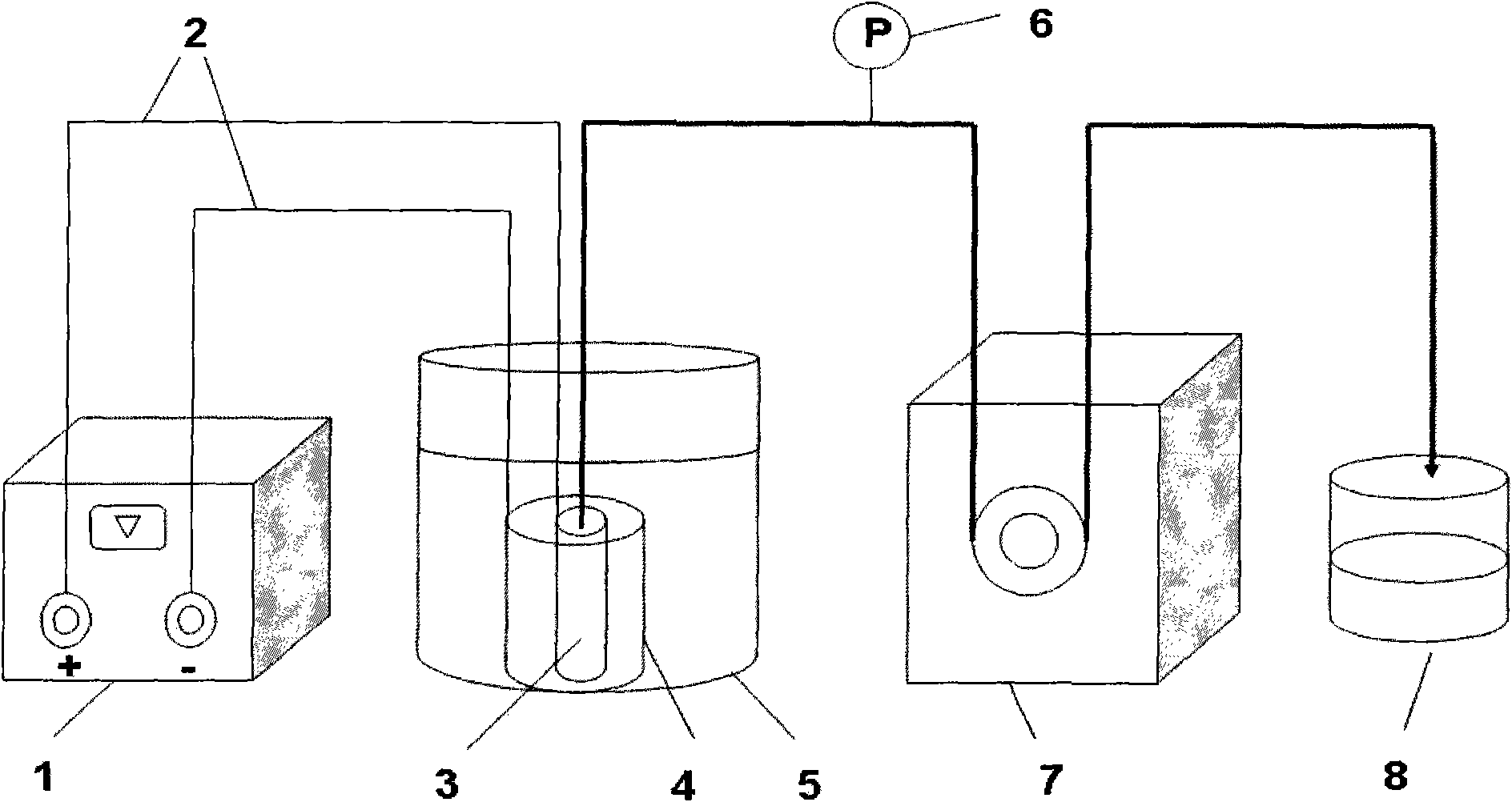

Embodiment 1

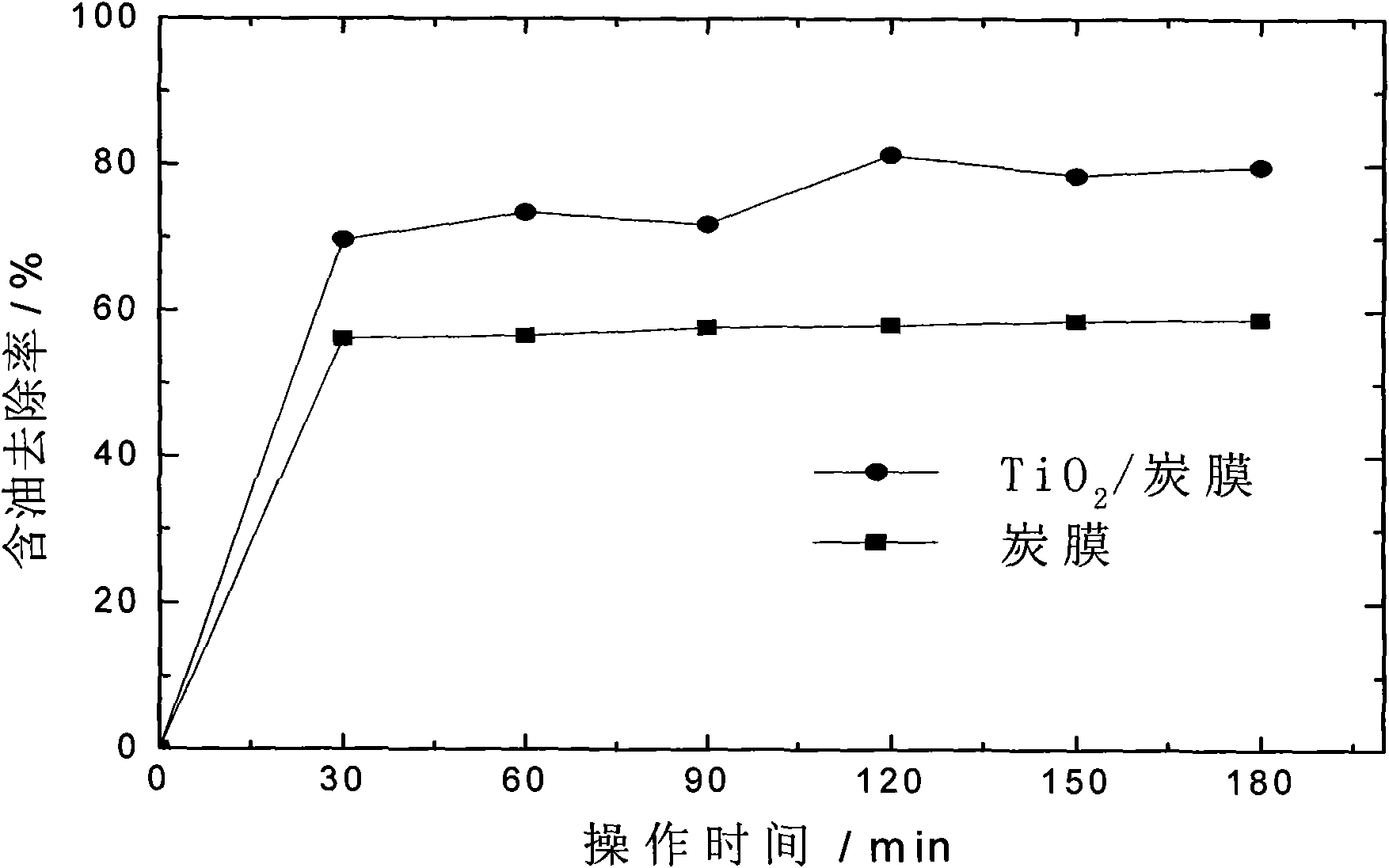

[0022] The feed liquid of the electrocatalytic membrane reactor is 3L of 100ppm simulated oily wastewater. The electrocatalytic composite membrane is used as the anode (the original membrane pore size is 0.6μm, the porosity is 41%), the stainless steel electrode is the cathode, and the effective area of the electrode is 20.6cm 2 , The electrode spacing is 14mm, the voltage is 4V, the current is 0.20-0.25A, the electrolyte concentration is 10g / l, and the pH is 4, press figure 1 Connect the device to adjust the transmembrane pressure difference to 0.025MPa. Experimental results: the initial water flux of the composite membrane is 110L / m 2 hbar, the interception rate of oily wastewater is 90%; after 4 hours of membrane fouling operation experiment, the membrane flux drops to 25% without electrocatalysis, while the membrane flux is basically unchanged with online electrocatalysis.

Embodiment 2

[0024] The feed liquid of the electrocatalytic membrane reactor is 2L of 200ppm simulated oily wastewater. The electrocatalytic composite membrane is used as the anode (the original membrane pore size is 0.4μm, the porosity is 37%), the stainless steel electrode is the cathode, and the effective area of the electrode is 15.4cm 2 , The electrode spacing is 14mm, the voltage is 3V, the current is 0.10-0.15A, the electrolyte concentration is 10g / l, and the pH value is 7, press figure 1 Connect the device to adjust the transmembrane pressure difference to 0.01MPa. Experimental results: the initial water flux of the composite membrane is 156L / m 2 hbar, the rejection rate of oily wastewater is 91%; under the same conditions of other operating parameters, the membrane flux when the electrocatalytic composite membrane reactor is used to treat wastewater is 75% higher than the flux in the single membrane separation treatment.

Embodiment 3

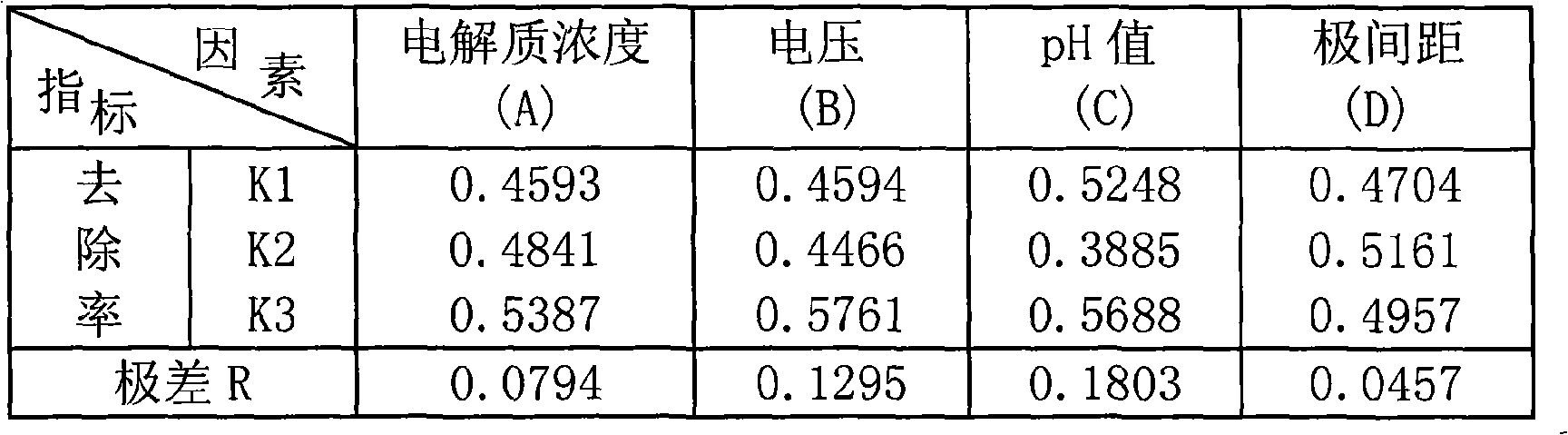

[0026] The electrocatalytic composite film is used as the anode, the stainless steel electrodes with different diameters are used as the cathode, and the effective area of the electrode is 20cm 2 In the electrocatalytic membrane reactor, the influence of various operating parameters such as electrolyte concentration, voltage, pH value, and electrode spacing on the electrochemical performance of the reactor was studied. The experimental factors and levels are shown in Table 1. By investigating the removal rate of pollutants under different conditions, the results and analysis are shown in Table 2, and the optimal operating parameters of the membrane reactor are obtained: electrolyte concentration 15g / l, voltage 4V, electrode spacing 39mm, pH value 7. And through the range analysis, it is concluded that the primary and secondary order of the influence of each parameter on the pollutant removal rate is pH, voltage, electrolyte concentration, and electrode spacing.

[0027] Table 1

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Effective area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com