Photoelectric conversion device and method for manufacturing the same

A photoelectric conversion device and manufacturing method technology, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., which can solve the problems of solar cell reliability concerns, inability to simultaneously achieve high productivity, and low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0069] One of the features of one aspect of the present invention is that the semiconductor layer exhibiting photoelectric conversion includes crystals in an amorphous structure, and the crystals penetrate between a pair of impurity semiconductor layers joined to form an internal electric field. In this embodiment, a photoelectric conversion device in which a plurality of unit elements are stacked is shown. When one aspect of the present invention is applied to a tandem or stacked type photoelectric conversion device, the layer exhibiting photoelectric conversion as at least one unit element is applied to an amorphous structure including penetration A crystalline semiconductor layer between a pair of impurity semiconductor layers joined to form an internal electric field.

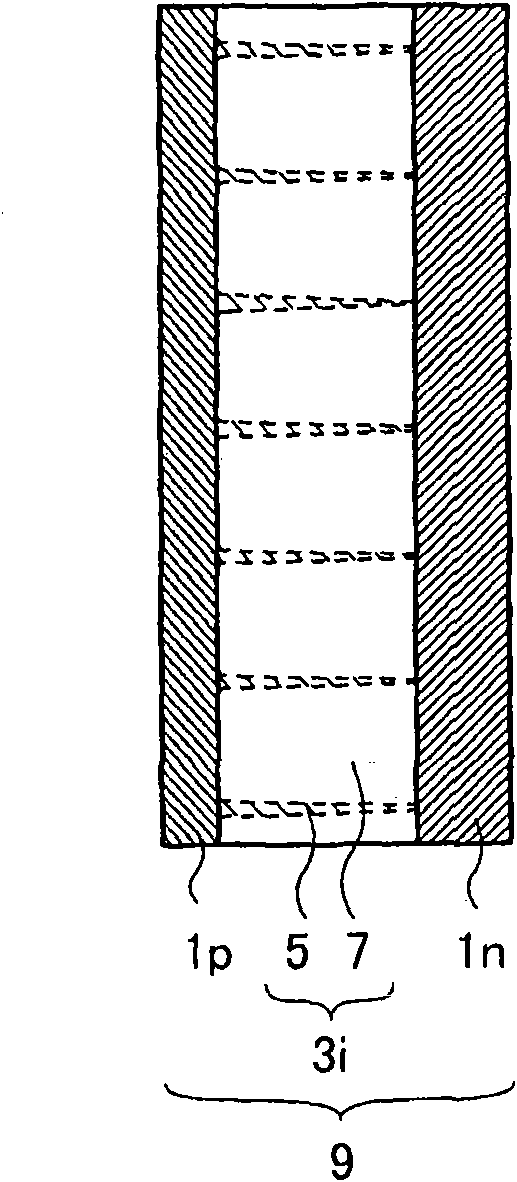

[0070] figure 1 A schematic diagram showing a unit element according to an aspect of the present invention. A unit element according to an aspect of the present invention has a structure in which a semiconduc...

Embodiment approach 2

[0124] In this embodiment, a photoelectric conversion device having a structure different from the above-mentioned embodiment is shown. Specifically, it shows the number of stacked unit elements and figure 2 Different examples of photoelectric conversion devices.

[0125] Figure 5A A single junction type photoelectric conversion device having one unit cell is shown. The photoelectric conversion device includes a unit element 40 composed of a p-type semiconductor impurity semiconductor layer 41p, an i-type semiconductor semiconductor layer 43i, and an n-type semiconductor impurity semiconductor layer 41n laminated on a substrate 2 on which the first electrode 4 is formed. And the second electrode 6 formed on the unit element 40, and includes at least one semiconductor junction. In the semiconductor layer 43i, crystals 45 are dispersed in the amorphous structure 47. In addition, the crystal 45 penetrates the semiconductor layer 43i between the impurity semiconductor layer 41p and...

Embodiment approach 3

[0129] In this embodiment, a photoelectric conversion device having a structure different from the above-mentioned embodiment is shown. Specifically, an example in which a low-concentration impurity semiconductor layer of the same conductivity type as the impurity semiconductor layer of the one conductivity type is formed at a junction of an impurity semiconductor layer of one conductivity type and an intrinsic semiconductor layer is shown.

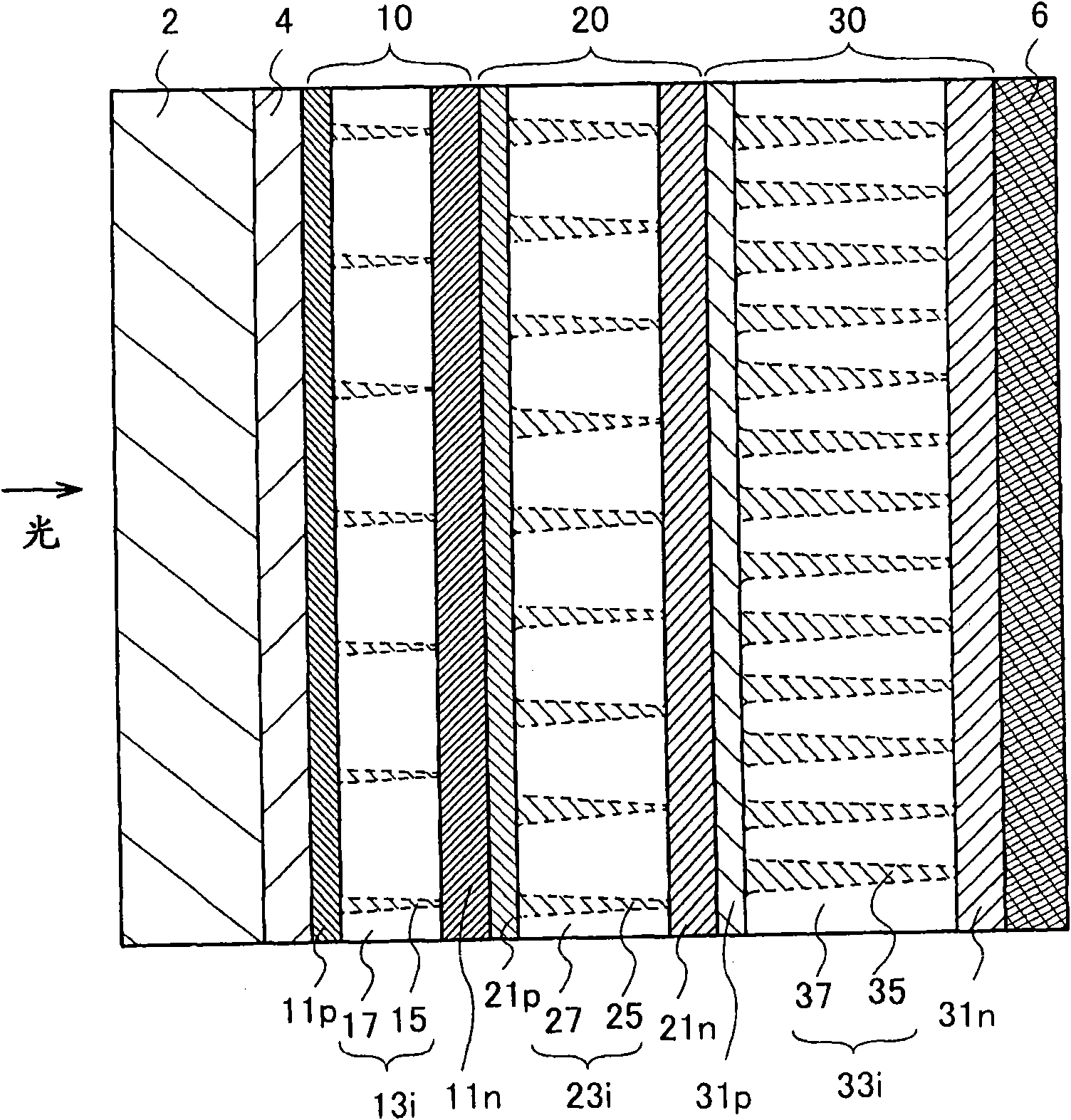

[0130] Figure 6A to 6C A stacked photoelectric conversion device in which three unit elements are formed is shown. in Figure 6A In this case, the first unit element 10, the second unit element 20, the third unit element 30, and the second electrode 6 are arranged from the side of the substrate 2 on which the first electrode 4 is formed. Impurity semiconductor layer 11p, first low-concentration impurity semiconductor layer 12p - , The first semiconductor layer 13i and the second impurity semiconductor layer 11n, the second unit element 20 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com