Hydrogenation and refining method of gasoline with poor quality

A technology for hydrorefining and low-quality gasoline, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, and can solve problems such as difficult operation, complicated process, high investment cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

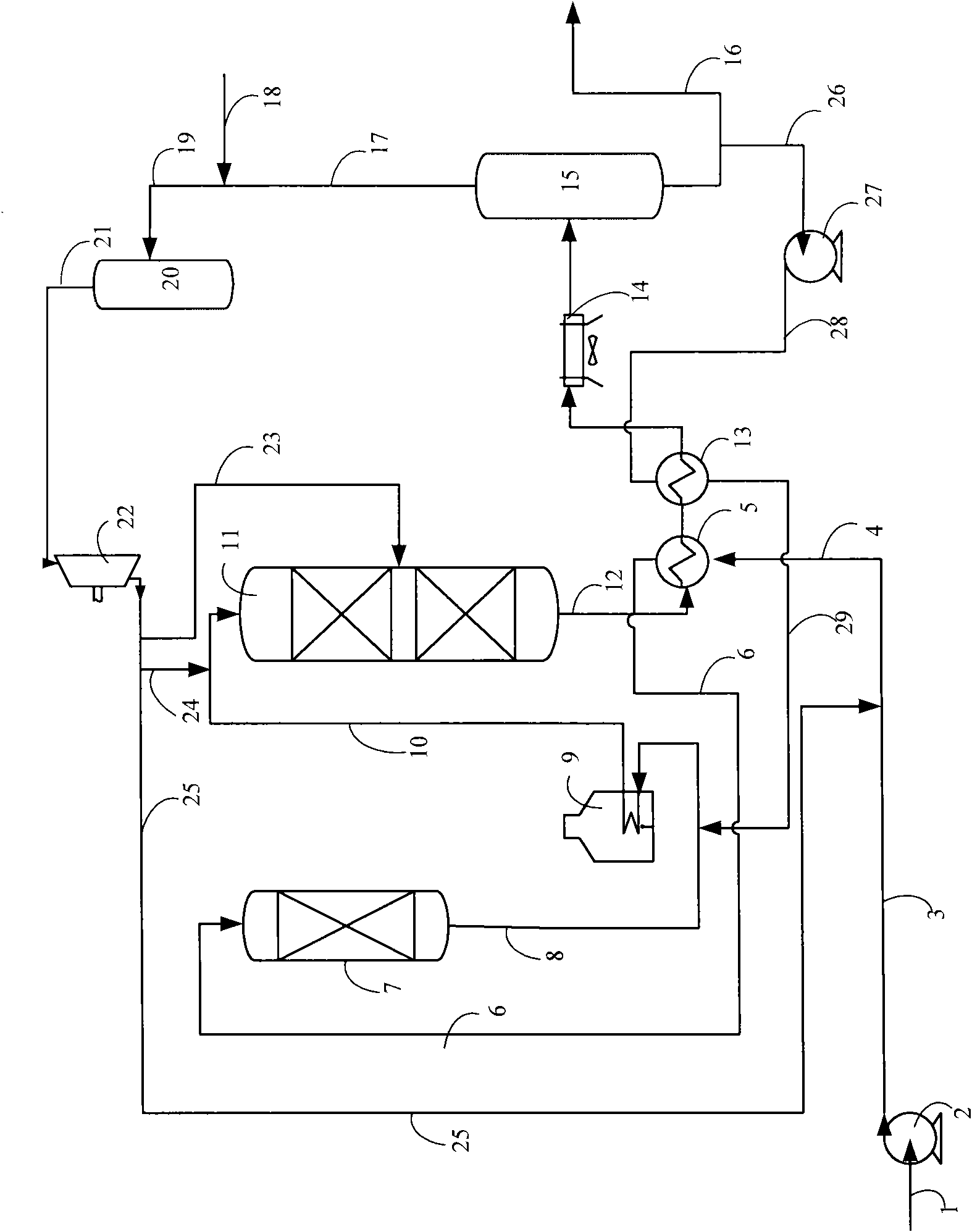

Image

Examples

Embodiment 1

[0029] A kind of coker gasoline is used as raw material oil, and the properties of the raw material oil are shown in Table 1. It can be seen from Table 1 that the diene value of the raw material oil is 3.5gI / 100g, the actual colloid is 12mg / 100ml, and the silicon content is 1.0μg / g. The sulfur content is as high as 6000μg / g, which is an inferior gasoline fraction.

[0030] The feedstock oil is mixed with circulating hydrogen and enters the hydrogenation protection reactor, where it contacts hydrogenation protection agent I, hydrogenation protection agent II and hydrogenation protection agent III for reaction, wherein hydrogenation protection agent I, hydrogenation protection agent II and hydrogenation protection agent The filling volume ratio of the hydrogen protection agent III is 1:2:3, the outlet effluent of the hydrogenation protection reactor is mixed with the hydrocoking gasoline, and the ratio of the fresh raw material and the circulating oil is 1:1. The mixture directl...

Embodiment 2

[0039] A kind of coker gasoline is used as the raw material oil, and the properties of the raw material oil are shown in Table 4. From Table 4, it can be seen that the diene value of the raw material oil is 3.6gI / 100g, the actual colloid is 57mg / 100ml, and the silicon content is 6.0μg / g. The sulfur content is as high as 7800μg / g, which is an inferior gasoline fraction.

[0040] The feedstock oil is mixed with circulating hydrogen and enters the hydrogenation protection reactor, where it contacts hydrogenation protection agent I, hydrogenation protection agent II and hydrogenation protection agent III for reaction, wherein hydrogenation protection agent I, hydrogenation protection agent II and hydrogenation protection agent The filling volume ratio of the hydrogen protection agent III is 1:1:3, the outlet effluent of the hydrogenation protection reactor is mixed with the hydrocoking gasoline, and the ratio of the fresh raw material and the circulating oil is 2:1. The mixture di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com