Lead-based de-arsenic catalyst

A technology for removing and transitioning metals, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, refined hydrocarbon oil, etc. Achieve a wide range of applications, simplify the process, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

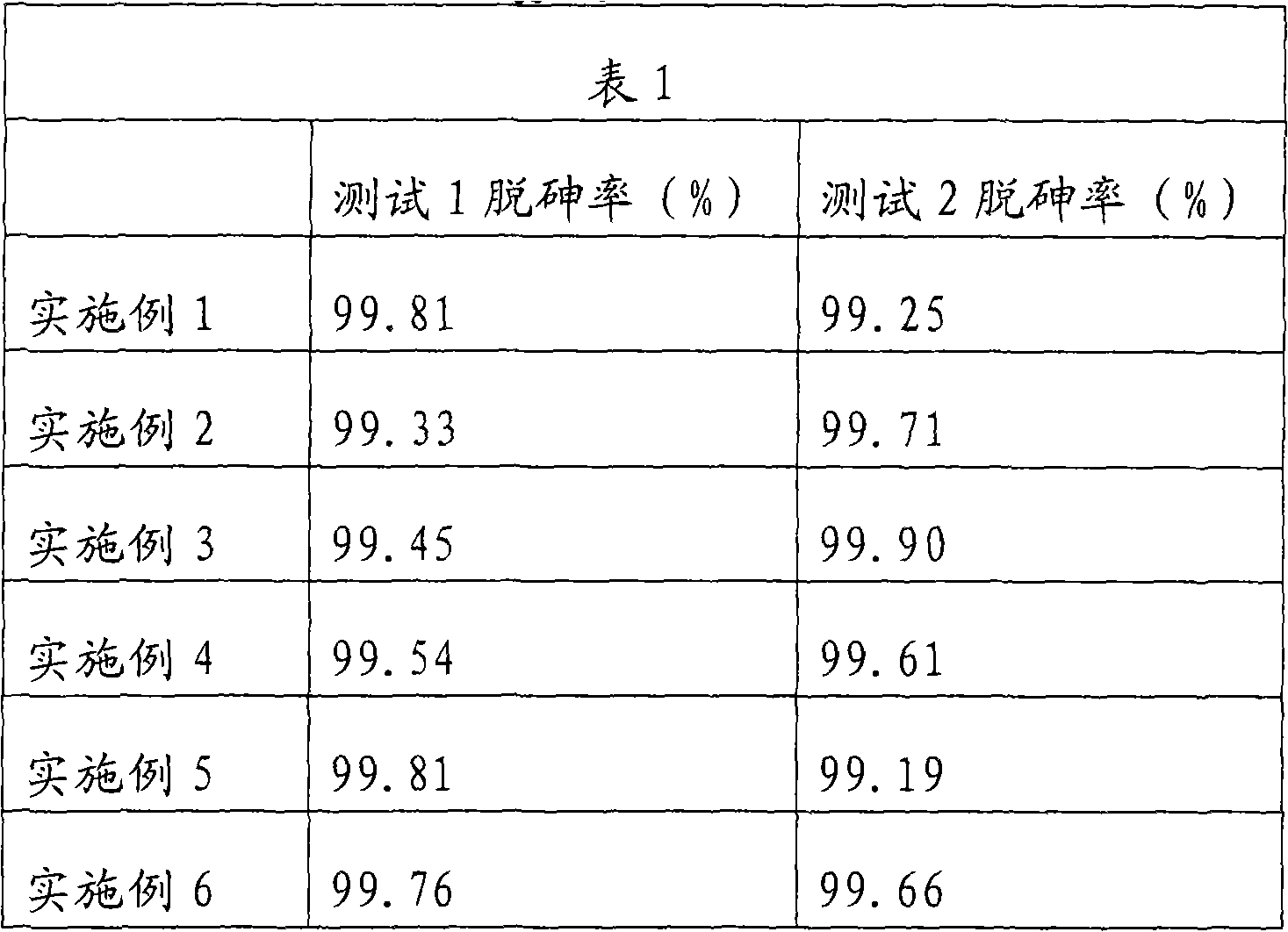

Examples

preparation example Construction

[0020] Preparation of lead-based arsenic-removing agent carrier of the present invention

[0021] to Al(OH) 3 Add appropriate amount of hydrochloric acid to the powder to prepare AlCl 3 Solution, add nitric acid to acidify, then neutralize with ammonia water, after aging, pressure filtration, pulping and other processes, and finally acidify and peptize at the ball forming station, and then prepare balls by dropping balls, at 500-700 ° C Roasting to get active Al 2 o 3 Balls with a pore volume of 0.4-0.6 mL / g.

[0022] Preparation of lead-based arsenic removal agent of the present invention

Embodiment 1

[0024] Assuming that the mass percentage of PbO in the finished lead-based arsenic removal agent is 10%, take 0.0448mol of lead acetate to make a saturated solution, use a sugar coating machine to spray and dip 80.00g of activated alumina balls, dry, roast at 400°C, and cool to Obtain the semi-finished product of lead-based arsenic removal agent.

[0025] In the present embodiment, with the mass percentage of NiO in the finished product lead-based arsenic removal agent being 10%, 0.1333mol Ni (NO 3 ) 2 Prepare a solution to spray and immerse the semi-finished lead-based arsenic removal agent, isolate the air, and roast at 500°C to obtain the finished lead-based arsenic removal agent.

Embodiment 2

[0027] Assuming that the mass percentage of PbO in the finished lead-based arsenic removal agent is 25%, take 0.1121mol of lead acetate to make a saturated solution, use a sugar coating machine to spray and dip 60.00g of activated alumina balls, dry, roast at 450°C, and cool to Obtain the semi-finished product of lead-based arsenic removal agent.

[0028] In this embodiment, the mass percentage of CoO in the finished lead-based arsenic removal agent is calculated as 15%, and 0.2000mol Co(NO 3 ) 2 Prepare a solution to spray and immerse the semi-finished lead-based arsenic removal agent, isolate the air, and roast at 500°C to obtain the finished lead-based arsenic removal agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com