Preparation method and use of molecular imprinting-absorbing extraction stirring rod

A molecular imprinting and stirring rod technology, applied in selective adsorption, chemical instruments and methods, ion exchange, etc., can solve the problems of low coating selectivity and single type of coating, achieve uniform coating, improve accuracy and Precision, effectiveness in avoiding competing adsorption problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

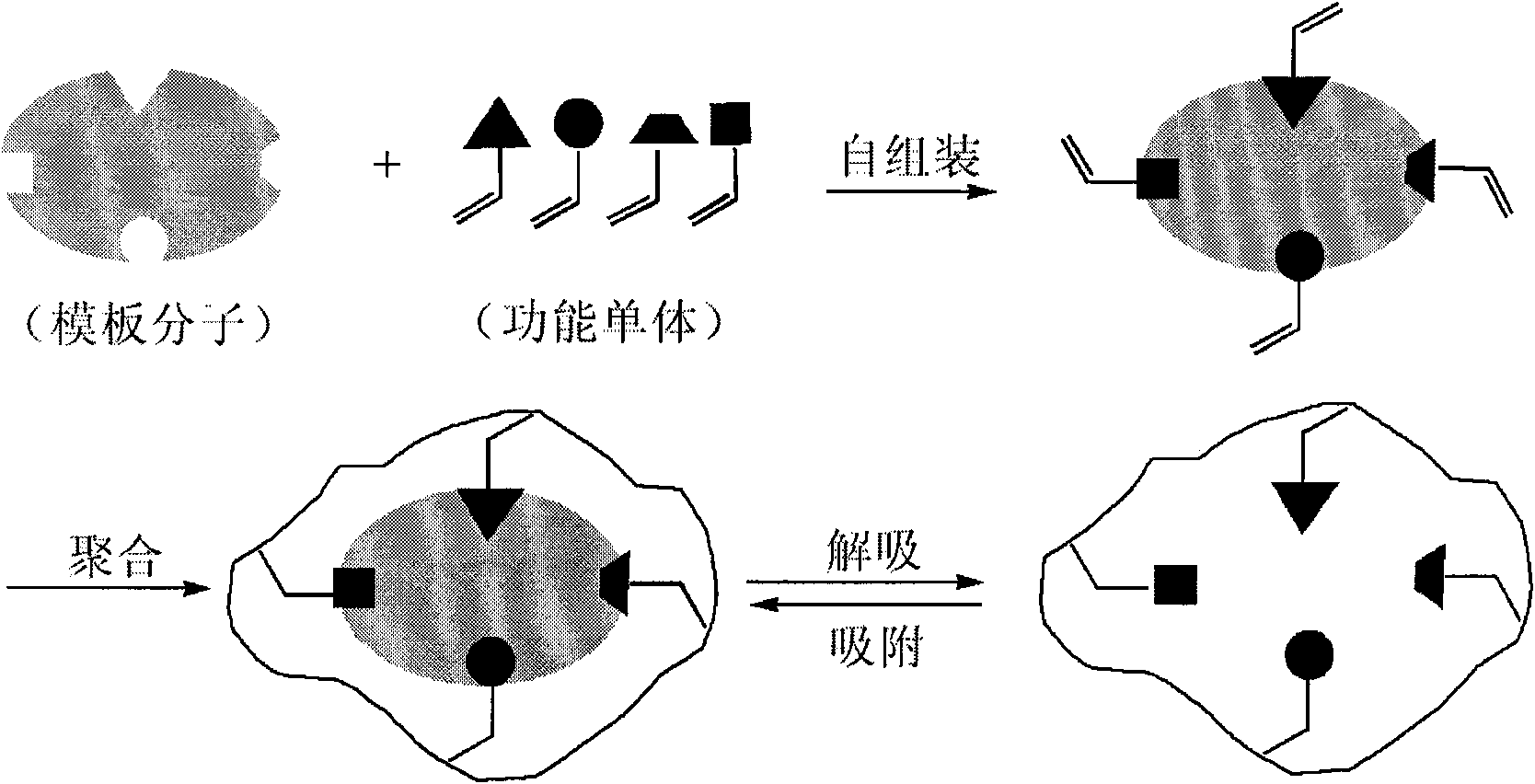

[0028] The preparation technology of the present invention is as follows:

[0029] Clean the inner and outer surfaces of the glass capillary with an inner diameter of 0.9-1.1 mm with tap water, then with distilled water, and dry in an oven at 120°C.

[0030]The pretreatment method of molecularly imprinted adsorption and extraction stirring rod substrate: sinter one end of the capillary on the flame of an alcohol lamp, then vertically insert it into a 1mol / L sodium hydroxide solution and soak for 8 hours, take it out and clean it with distilled water, and then vertically insert it into a 1mol / L sodium hydroxide solution Soak in hydrochloric acid solution for 1 hour, take it out, wash it with distilled water, and then wash it with methanol, then place it in an oven at 150°C for 1 hour, and cool it to room temperature for later use. Insert the activated capillary vertically into a 1:3 (v / v) diluted 3-methacryloyl-propyl-trimethoxysilane acetone solution, place it for 3-4 hours, p...

Embodiment 1

[0035] Preparation of Stir Bar for Molecularly Imprinted Adsorption and Extraction of Ractopamine:

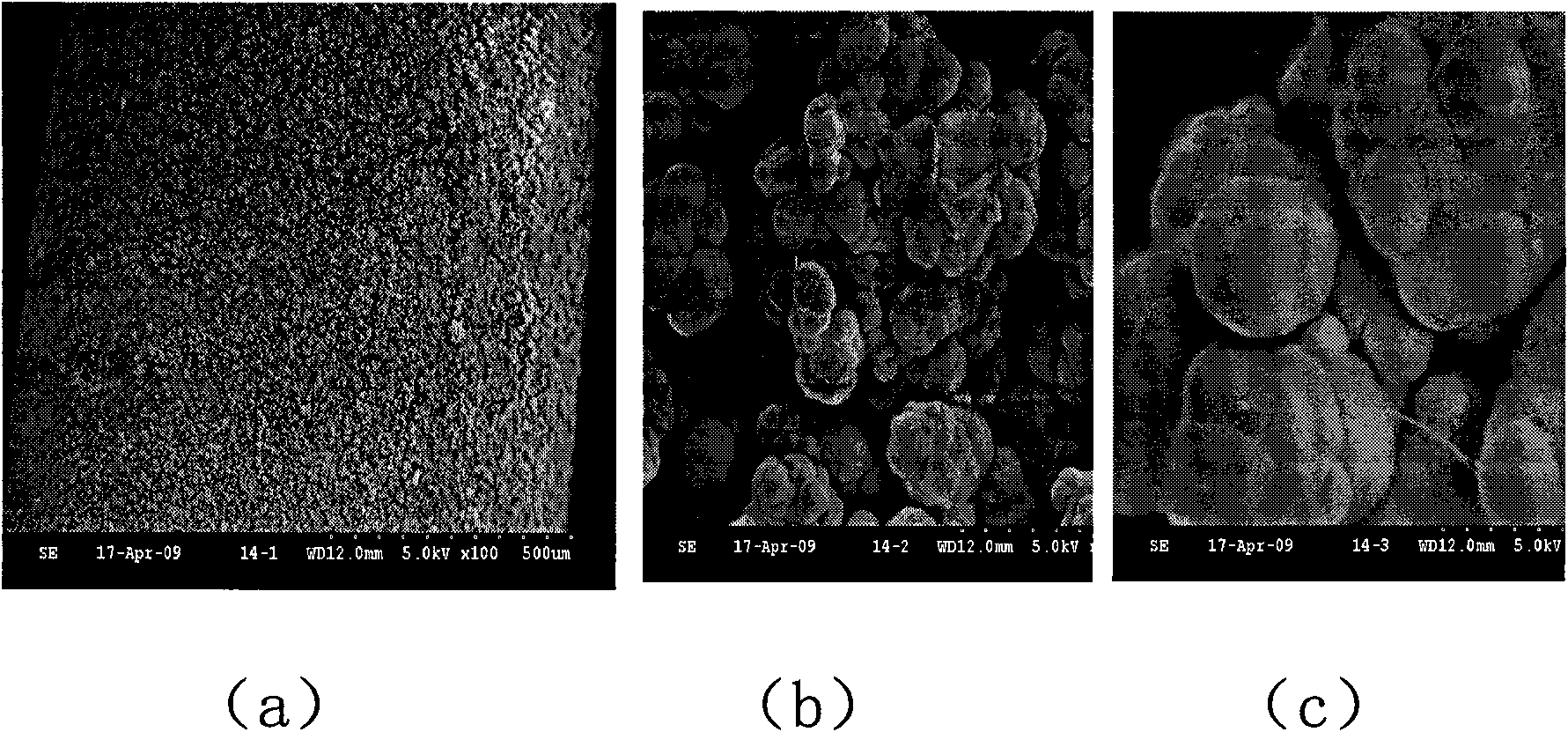

[0036] Weigh 405.0 mg of ractopamine powder, dissolve it in 20.0 mL of methanol, add 0.4 mL of methacrylic acid, mix well, and place at room temperature for 12 hours. Add 4.6mL of ethylene glycol dimethacrylate, then add 45.9mg of azobisisobutyronitrile, mix well, ultrasonically degas for 5 minutes, take 1.5mL of the above prepolymerization solution in a test tube, put a silanized Reagent-treated glass capillaries are then purged with nitrogen to remove oxygen. The test tube was sealed with a rubber stopper and heated in a water bath at 60°C in a nitrogen blowing apparatus. After the polymerization reaction was carried out for 2.5 hours, the polymer solution was nearly solidified, and the glass capillary was pulled out vertically, and dried with nitrogen gas, and the polymerization was continued in a 60°C water bath for 24 hours after purging nitrogen gas to remove oxygen. Th...

Embodiment 2

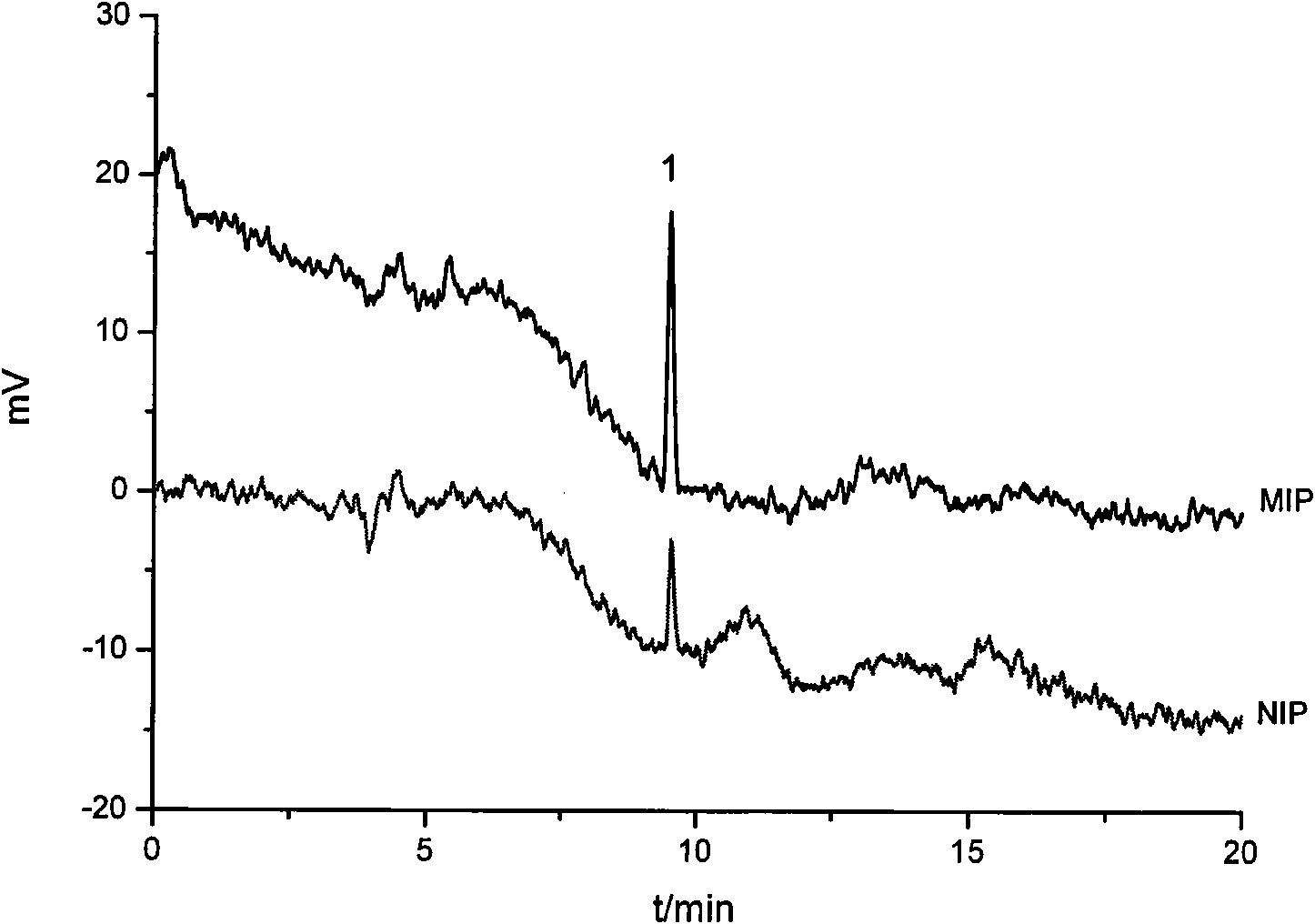

[0045] Preparation of Stir Bar for Molecularly Imprinted Adsorption and Extraction of Terbutyzine:

[0046] Weigh 459.6 mg of terbutyzine powder, dissolve in 20.0 mL of toluene, add 0.7 mL of methacrylic acid, mix well, and place at room temperature for 12 hours. Add 2.6mL of trimethylolpropane trimethacrylate, then add 26.4mg of azobisisobutyronitrile, mix evenly, degas by ultrasonic for 5min, take 1.5mL of the above prepolymerization solution in a test tube, put it into a The glass capillary treated with silylating reagent was then purged with nitrogen to remove oxygen. The test tube was sealed with a rubber stopper and heated in a water bath at 60°C in a nitrogen blowing apparatus. After the polymerization reaction was carried out for 2 hours, the polymer solution was nearly solidified, the glass capillary was pulled out vertically, and dried with nitrogen gas, and the polymerization was continued in a 60°C water bath for 24 hours after purging nitrogen gas to remove oxyge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com