Steel material having excellent corrosion resistance

A technology with excellent corrosion resistance and excellent corrosion resistance, applied in the field of raw materials of steel structures, it can solve the problem of no exposed corrosion resistance, and achieve the effect of excellent corrosion resistance and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

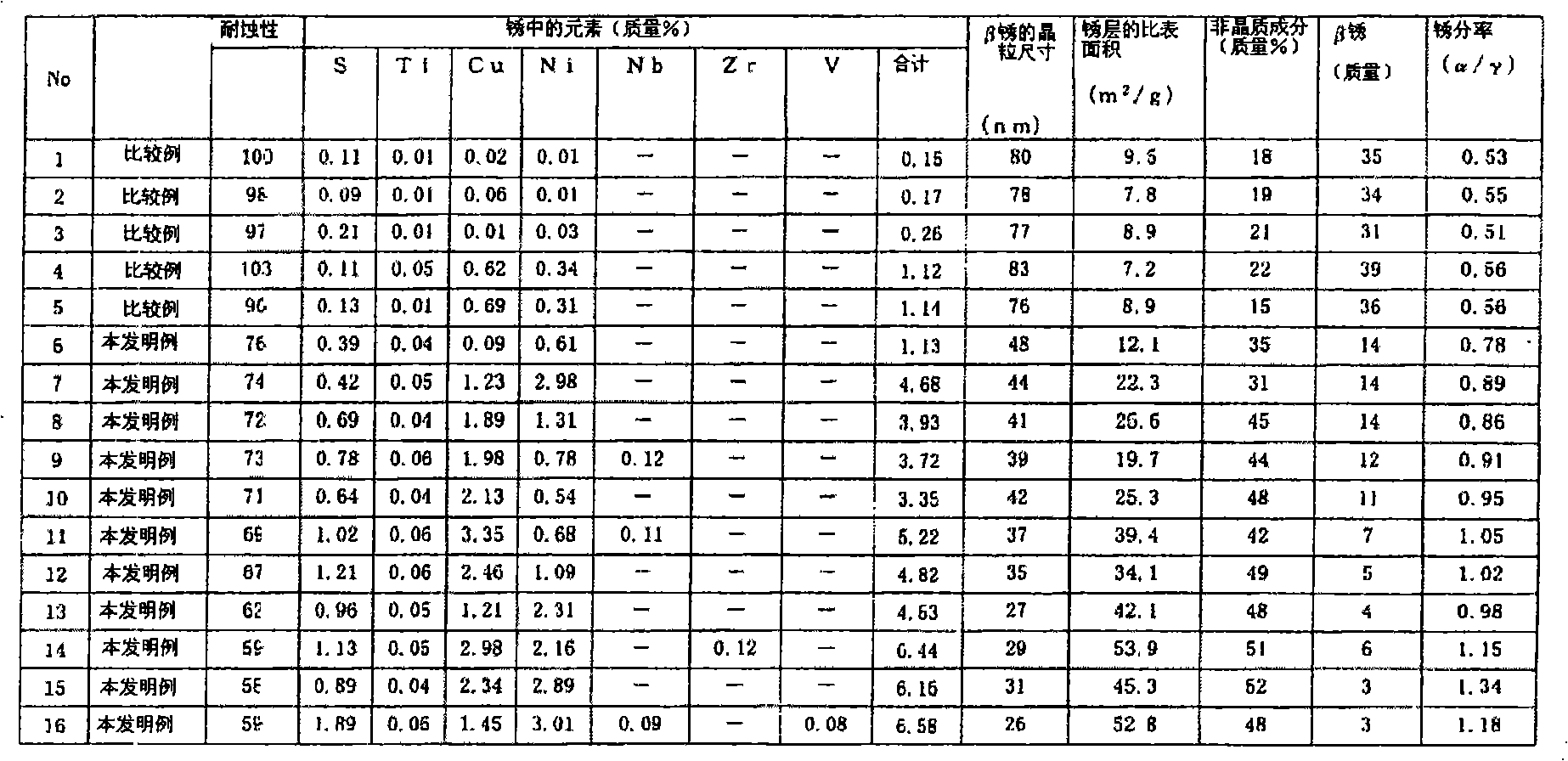

[0067] Hereinafter, the present invention will be specifically described by comparing Examples satisfying the requirements of the present invention and Comparative Examples not satisfying the requirements of the present invention. In addition, the following examples are representative, but this invention is not limited to these examples.

[0068] (Example No.1~16)

[0069]Ingots having the chemical compositions shown in Table 1 were dissolved in respective laboratory grade atmospheres. The casting mold used a 45 kgf angle casting mold for thin plates, and produced ingots having the chemical compositions shown in Table 1. Next, rough rolling is performed on these ingots. The heating condition is 1100°C×30 minutes, and the hot rolling rolling table is not specified, so that the final thickness is 25mm×the width×length (here, the so-called "the width" means that the thickness of the plate is not particularly specified. The width is in the state of the width corresponding to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com