Air tightness detecting system used for lithium battery and detecting method thereof

A technology of air tightness detection and lithium-ion battery, which is applied in the field of detection system, can solve the problems of low degree of detection automation, reliability dependence on operators, and negative impact of subsequent processes, so as to improve the detection production cycle and improve the repeatability accuracy , Improve the effect of detection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

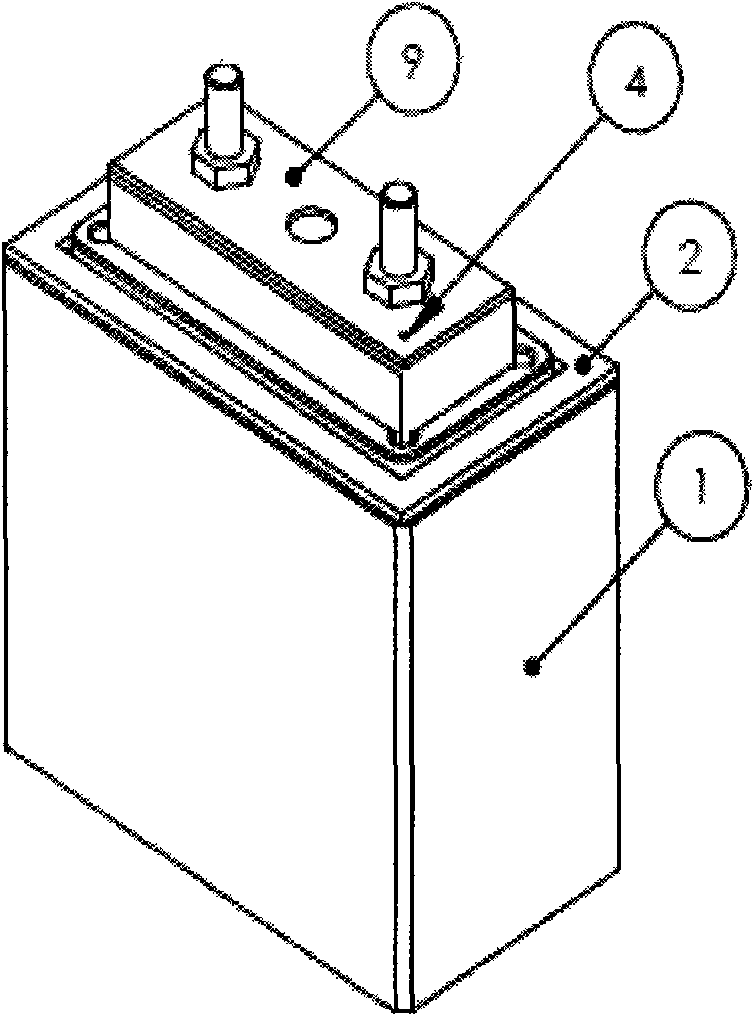

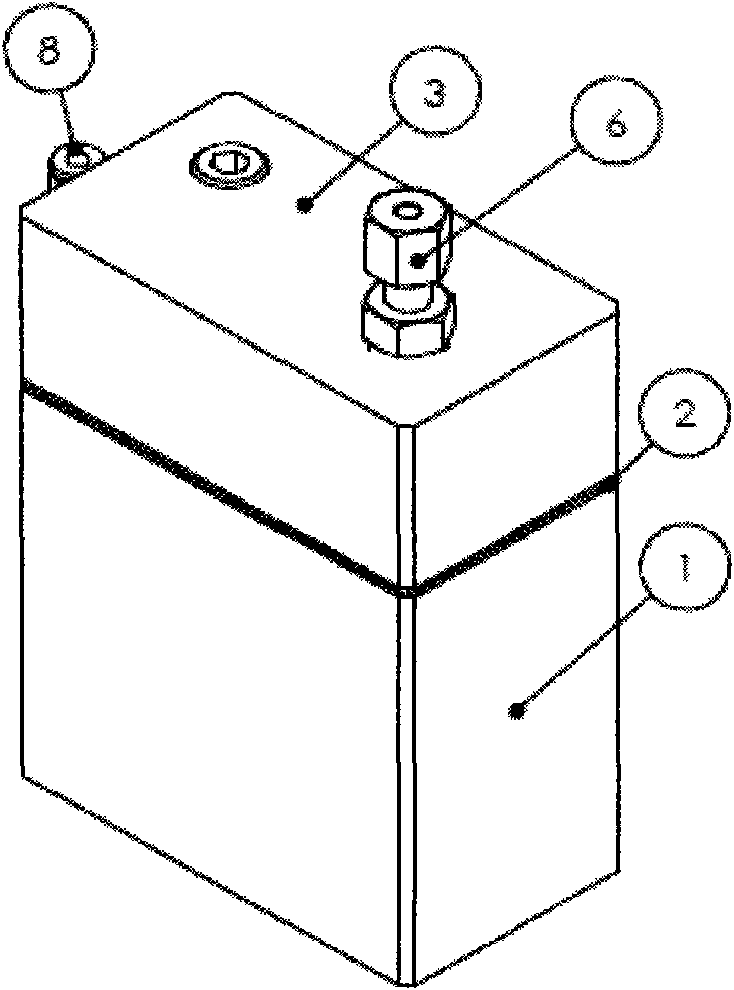

[0032] Attached Figure 2 and attached image 3 Description of the main components and details: 1 base, 2 first gasket, 3 upper sealing cover, 4 battery liquid injection hole, 5 second gasket, 6 inner cavity tube joint of workpiece, 7 outer cavity of workpiece, 8 outer workpiece Lumen tube connector, 9 batteries, 10 inner cavity of workpiece.

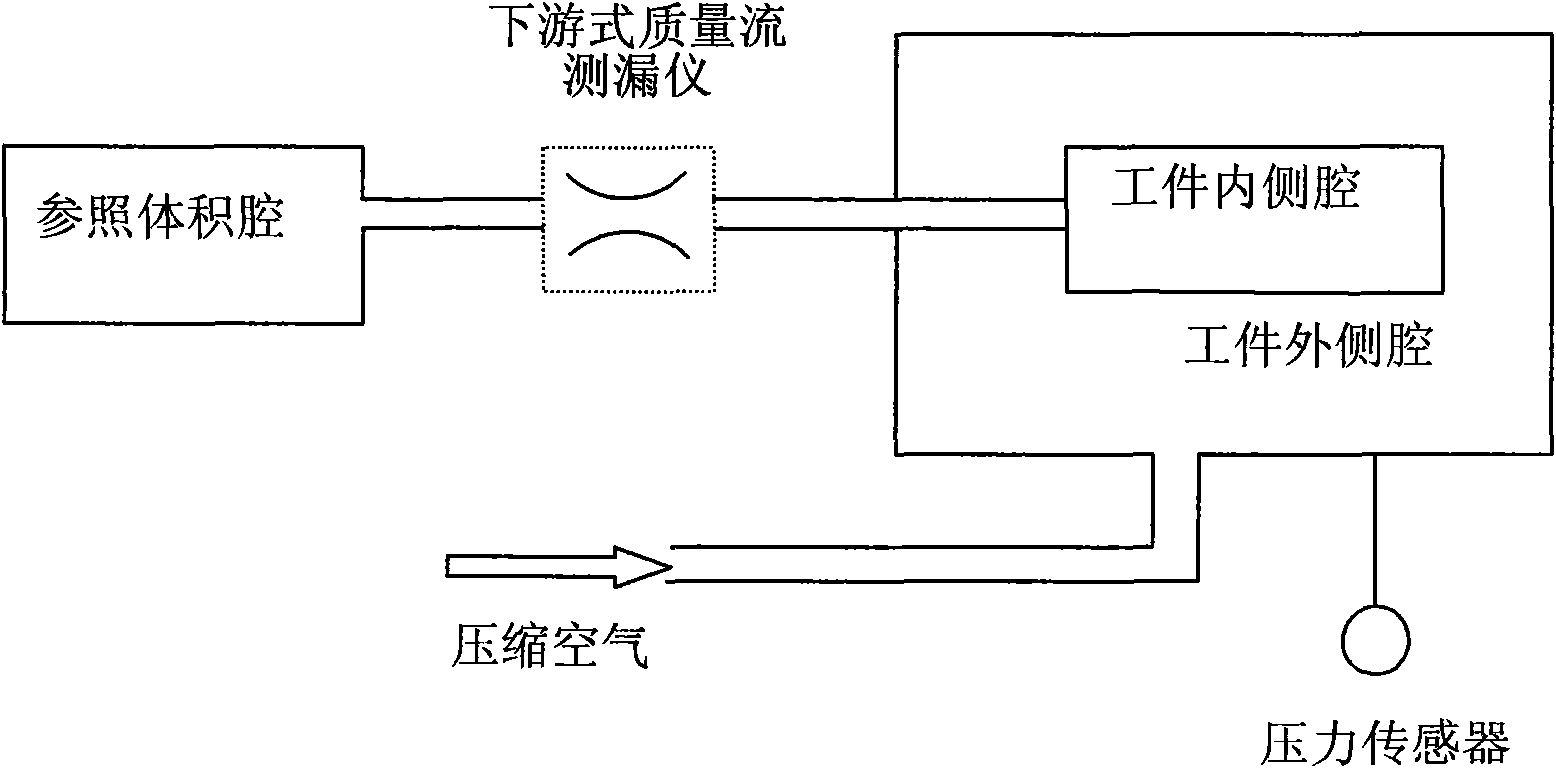

[0033] The detection principle of the detection system of the present invention is based on the downstream flow leakage detection principle, and its detection principle is as follows: figure 1 As shown, the workpiece to be tested is a closed airtight container (the inner cavity of the workpiece), and its leakage is detected under a given pressure. Place the workpiece under test in a sealed cavity (outside cavity of the workpiece). The inner chamber pressure of the workpiece is gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com