Acoustic velocimetry SF6 gas leakage monitoring and warning system

A gas leakage, monitoring and alarming technology, applied in the direction of detecting the occurrence of fluid at the leakage point, using sonic/ultrasonic/infrasonic waves for material analysis, measuring devices, etc. On-line detection and other problems, to meet the needs of the on-site environment, the influence of environmental factors is small, and the detection reliability is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

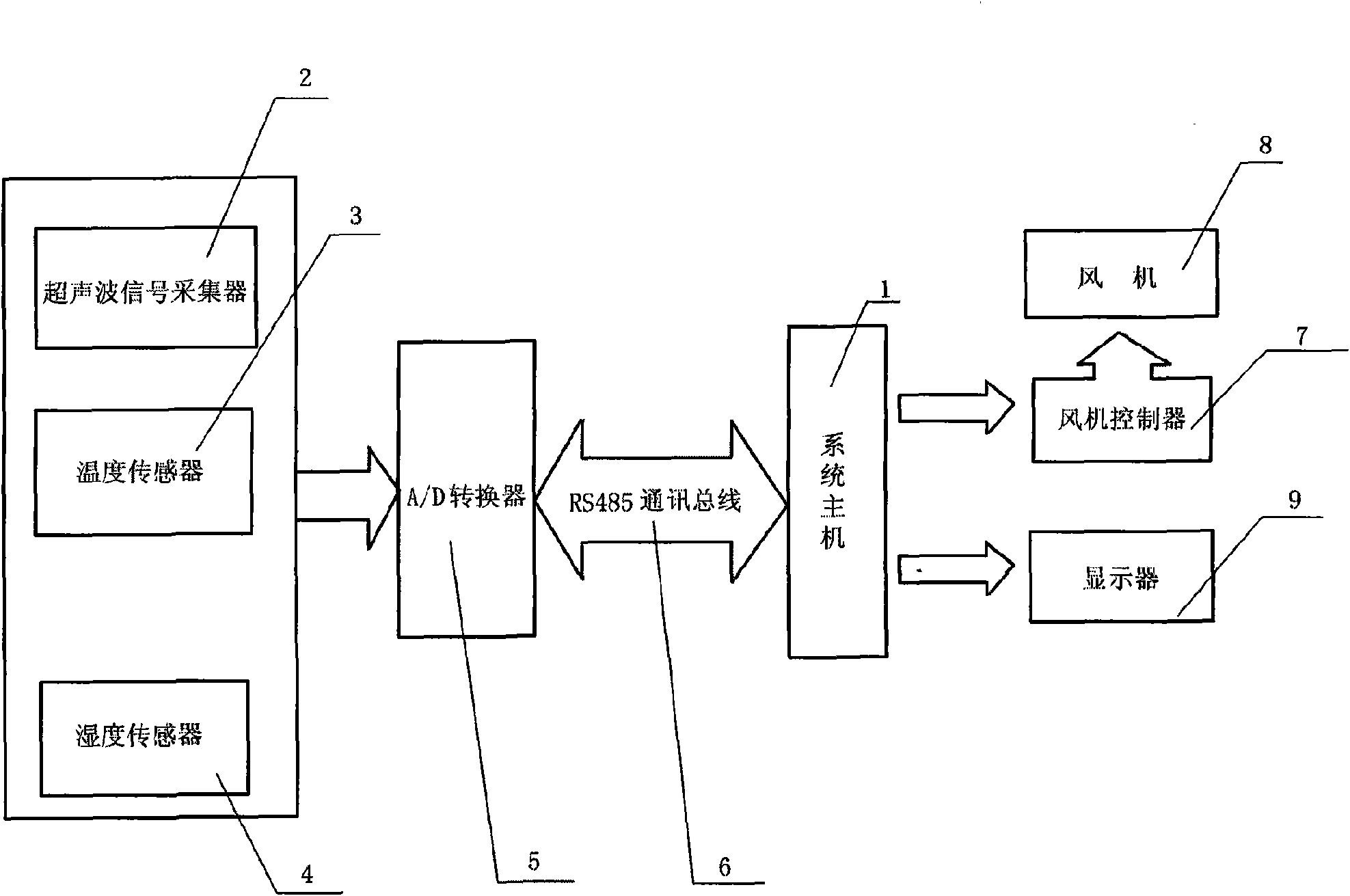

[0009] exist figure 1 Among them, the present invention is a kind of sonic velocimetry SF6 gas leak monitoring and warning system, and it comprises signal collector, A / D converter 5, system main frame 1 and peripheral equipment, the input terminal of signal collector and A / D converter 5 connection, the signal collector is an ultrasonic signal collector 2, which is provided with a collection cavity, an ultrasonic generator is installed at one end of the collection cavity, and the other end is an ultrasonic receiver, and the ultrasonic receiver measures from the transmitting end of the ultrasonic generator to the ultrasonic receiving The time interval experienced by the receiving end of the device, the time interval signal is collected, and the output end of the A / D converter 5 adopts the RS-485 field bus 6 to connect with the system host 1, and the interval signal is transmitted to after being converted by the A / D converter 5 System host 1, after processing, the system host 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com