Method of high-efficiency pretreatment on biomass

A biomass and pretreatment technology, applied in the direction of lignin derivatives, chemical instruments and methods, monosaccharides, etc., can solve the problems of lack of efficient pretreatment methods, no industrialized methods, high cost of cellulase, etc. , to achieve the effect of promoting the development of green agriculture, realizing waste utilization and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

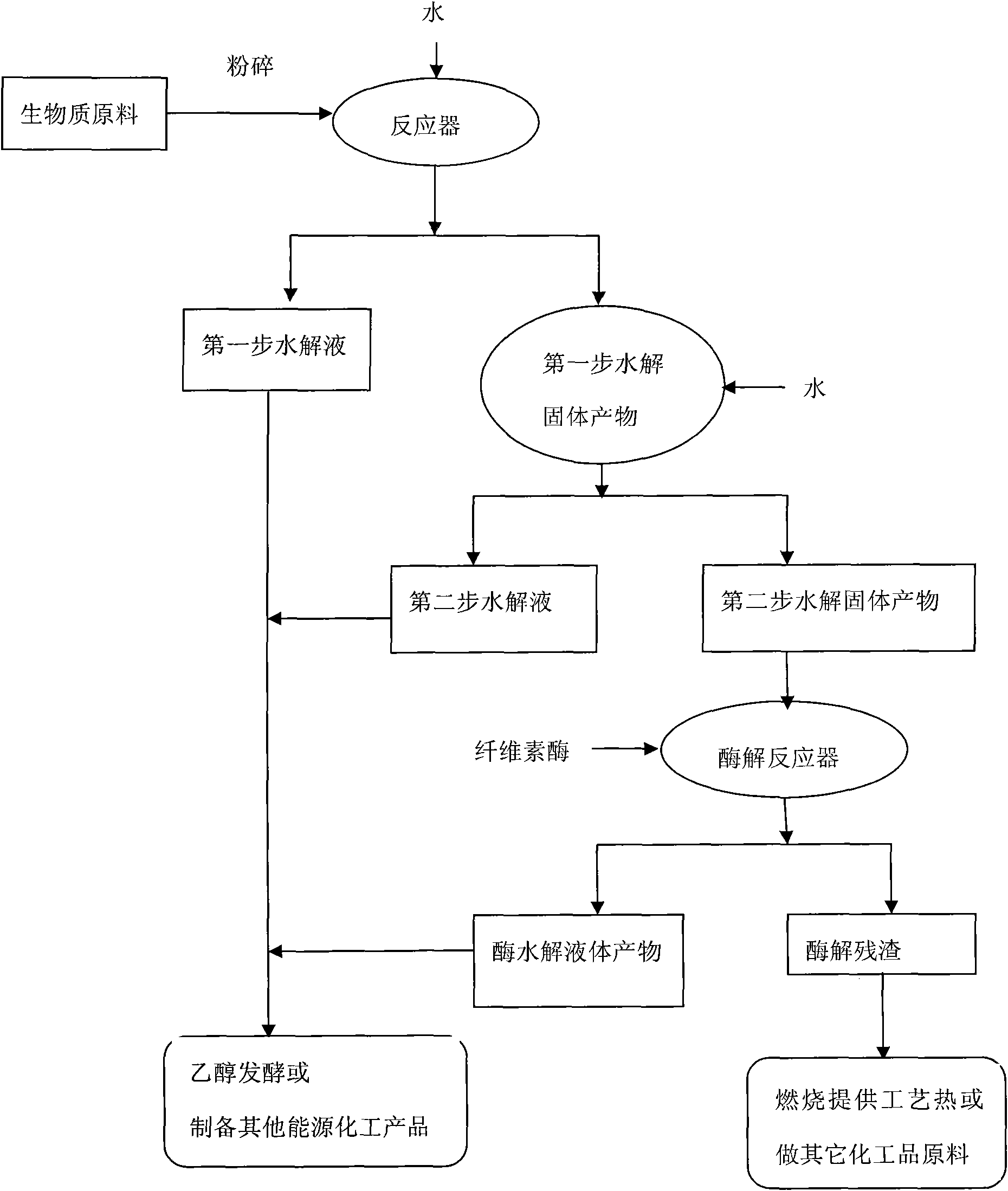

Image

Examples

Embodiment 1

[0039] Use eucalyptus as the raw material for hydrolysis, crush and sieve it, use 0.5-2mm eucalyptus wood chips as the raw material, add water according to the mass ratio of liquid to solid ratio of 20:1, feed the material into the high-pressure reactor, close the reaction system, and stir at a speed of 500r / Min, under the condition of pressure 2Mpa, react at 160°C for 60min, or at 4Mpa at 180°C for 20min, or at 4Mpa at 200°C for 10min, to obtain the highest value of xylose and its oligosaccharide products, cool and collect the liquid product, and complete The first step of pretreatment: quickly pour deionized water at room temperature into the kettle, with a liquid-solid ratio of 20:1; heat to 200°C and keep the liquid product at a pressure of 4Mpa for 30 minutes to collect, or heat to 240°C to keep the liquid product for 20 minutes to collect , or heated to 260°C, cooling and collecting the liquid product immediately; add water to the kettle, wait for the solid product to co...

Embodiment 2

[0041] Use eucalyptus as the raw material for hydrolysis, crush and sieve it, use 0.5-2mm eucalyptus wood chips as the raw material, add water at a mass ratio of liquid to solid 5:1, put it into a high-pressure reaction system, seal the reaction system, and heat it to 180°C. Under the condition of a pressure of 10Mpa, react for 20 minutes, cool and collect the liquid product, and complete the first step of pretreatment; quickly pour deionized water at room temperature into the kettle, with a liquid-solid ratio of 5:1, heat to 200°C for 20 minutes, and immediately The liquid product is cooled and released, and water is added to the reactor. After the solid product is cooled to room temperature, it is taken out to complete the second step of pretreatment; the cooled solid product is the product that has undergone the second step of variable temperature pretreatment, and it is used as the raw material for enzymatic hydrolysis. Enzyme hydrolysis, enzymatic hydrolysis conditions: pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com