Method for casting as-cast high-tenacity cast iron bearing cover of locomotive

A high-toughness, bearing cap technology, applied in the field of casting, can solve the problems of increasing product production energy consumption, difficulty in ensuring dimensional accuracy, and long production cycle, so as to avoid sand washing defects, reduce the possibility of oxygen slag, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The casting method of the locomotive as-cast high-toughness nodular iron bearing cap of the present invention comprises the following steps:

[0052] (1) Sand mixing molding, core making and molding

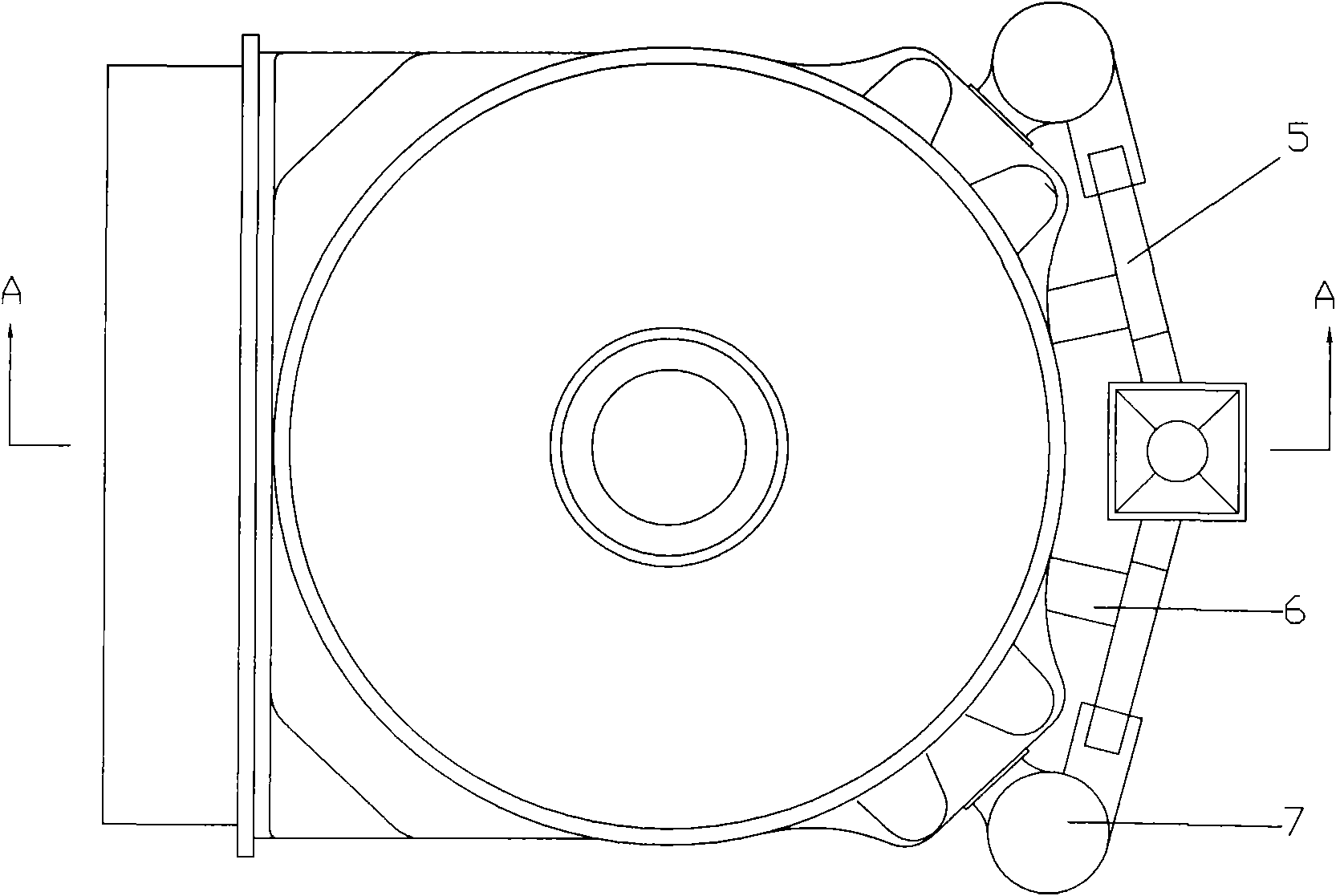

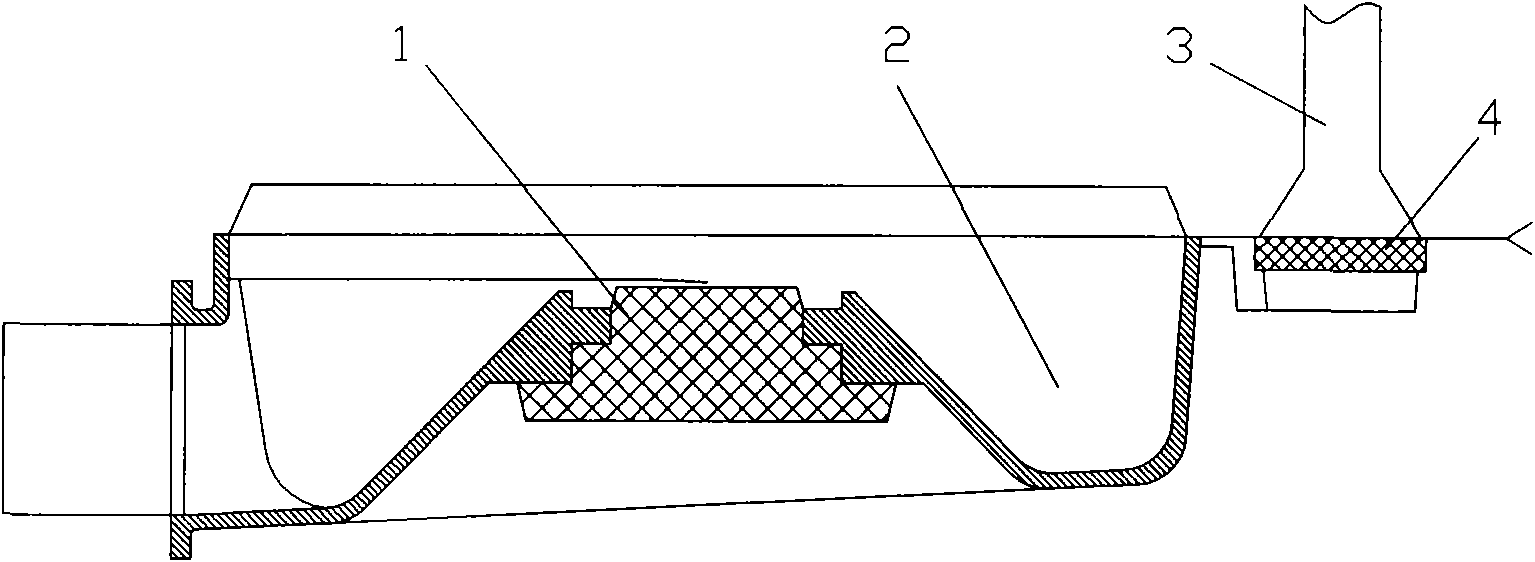

[0053] The bearing cover is made of furan resin self-setting sand and the cold iron core is placed when the sand is mixed. After the molding and core making, the mold is ejected, the mold is repaired, the paint is applied, the surface is dried, and the sand core 2 is lowered before the mold is closed, and the sprue 3 Place the ceramic foam filter piece 4 at the bottom, then form the top and bottom, tighten the box with bolts and wait for pouring see figure 1 , figure 2 .

[0054] (2) Charge smelting

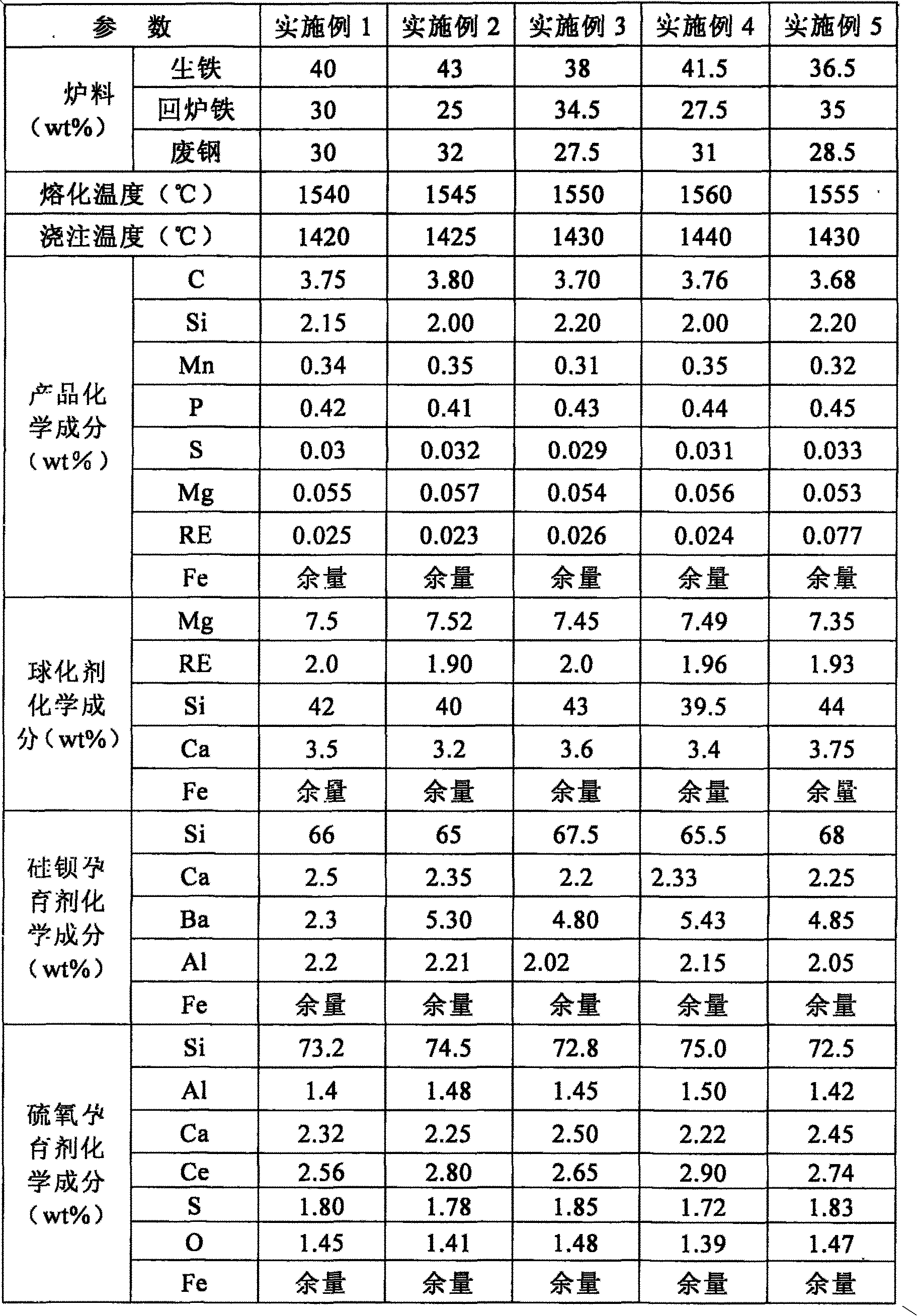

[0055] First configure the charge, the weight ratio of the charge is: 40% pig iron, 30% returned iron, 30% scrap steel; then put the prepared charge into the medium frequency induction furnace for molten iron melting, the melting temperature is 1540 ℃, stand still Keep w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com