Doping modified phase change material and phase change storage unit containing same and preparation method thereof

A technology of phase-change memory and phase-change material, which is applied in the field of phase-change memory device unit and its preparation, phase-change material and phase-change memory device unit containing the material and its preparation field, which can solve the problems that cannot meet the actual application requirements, chip Problems such as poor data retention and low crystallization temperature are achieved to overcome the effects of poor data retention, low power consumption, and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present invention contains (Sb 2 Se 3 ) 100-x Y x The preparation process of the phase change memory device unit of the phase change material is as follows:

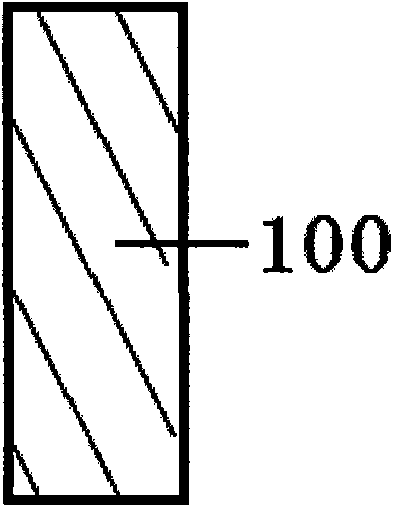

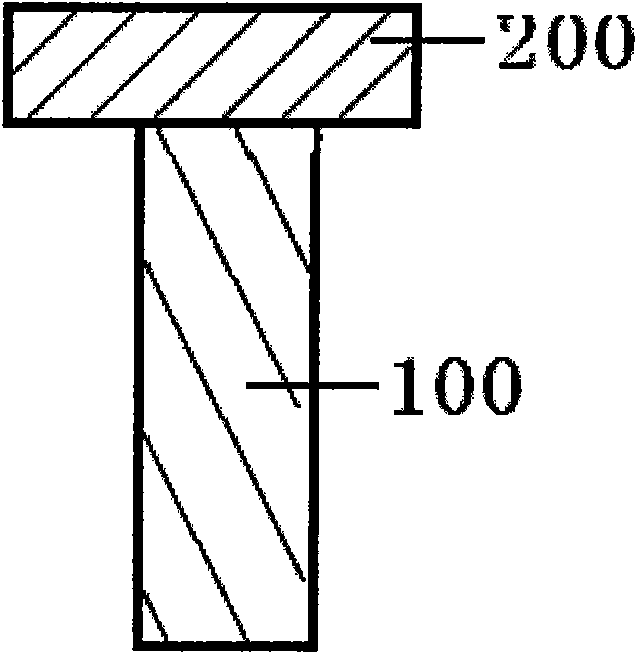

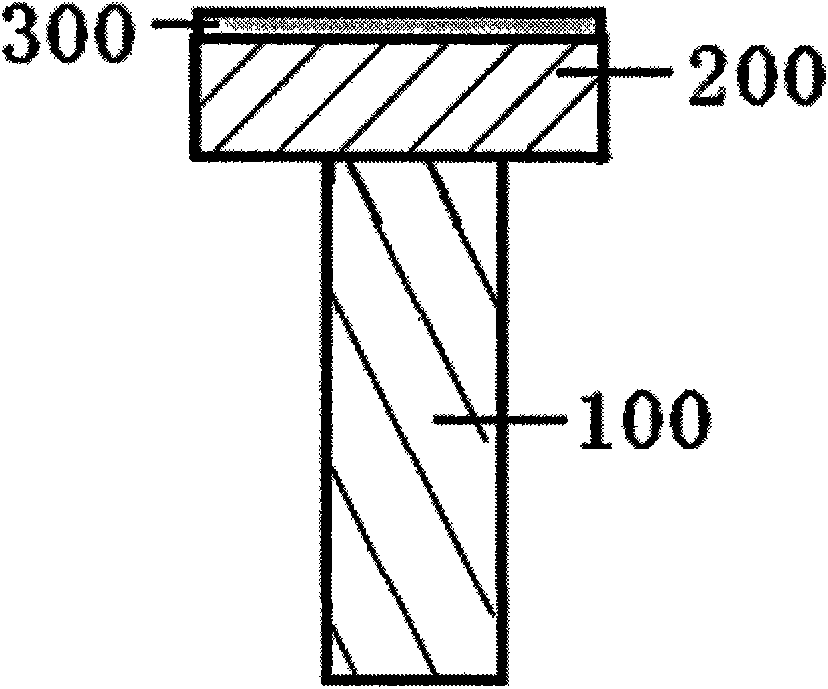

[0034] Step 1: See figure 1, using sputtering, evaporation, chemical vapor deposition (CVD), plasma enhanced chemical vapor deposition (PECVD), low pressure chemical vapor deposition (LPCVD), metal compound vapor deposition (MOCVD), molecular beam epitaxy The lower electrode layer 100 is prepared by any one of (MBE), atomic vapor deposition (AVD) or atomic layer deposition (ALD). In this embodiment, the lower electrode layer 100 is preferably prepared by CVD. The material of the lower electrode layer 100 is one of the single metal materials W, Pt, Au, Ti, Al, Ag, Cu or Ni, or an alloy material composed of any two or more of the single metal materials, or The nitride or oxide of the single metal material is preferably W in this embodiment. The resulting W electrode had a diameter of 80 nm and a height of...

Embodiment 2

[0042] The same technical solution as in the first embodiment is adopted, except that the preparation method of the phase-change material layer 300 is changed to AVD or ALD, and the rest of the steps are exactly the same as in the first embodiment, and the same technical effect can also be achieved.

Embodiment 3

[0044] Adopt the same technical scheme as embodiment one or two, the difference is that the phase change material in embodiment one or two is changed into (Sb 2 Se 3 ) 92 N 8 . where for Sb 2 Se 3 The element for material doping is any one of C, N or O, preferably N here. The doping of N adopts the reactive magnetron sputtering method, and the process parameters are: the background pressure is 1×10 -5 Pa, the gas pressure during sputtering is 0.3Pa, Ar / N 2 The ratio of the gas flow rate is 25:1, the sputtering power is 500W, and the substrate temperature is 25°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com