Method for producing battery-grade ferrous oxalate by using ferrous sulfate as titanium pigment byproduct

A technology of ferrous sulfate and ferrous oxalate, applied in the preparation of carboxylate, organic chemistry and other directions, can solve the problems of insufficient utilization of resources, complex process, complicated process, etc., and achieve stable product quality, good product quality, and process technology. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

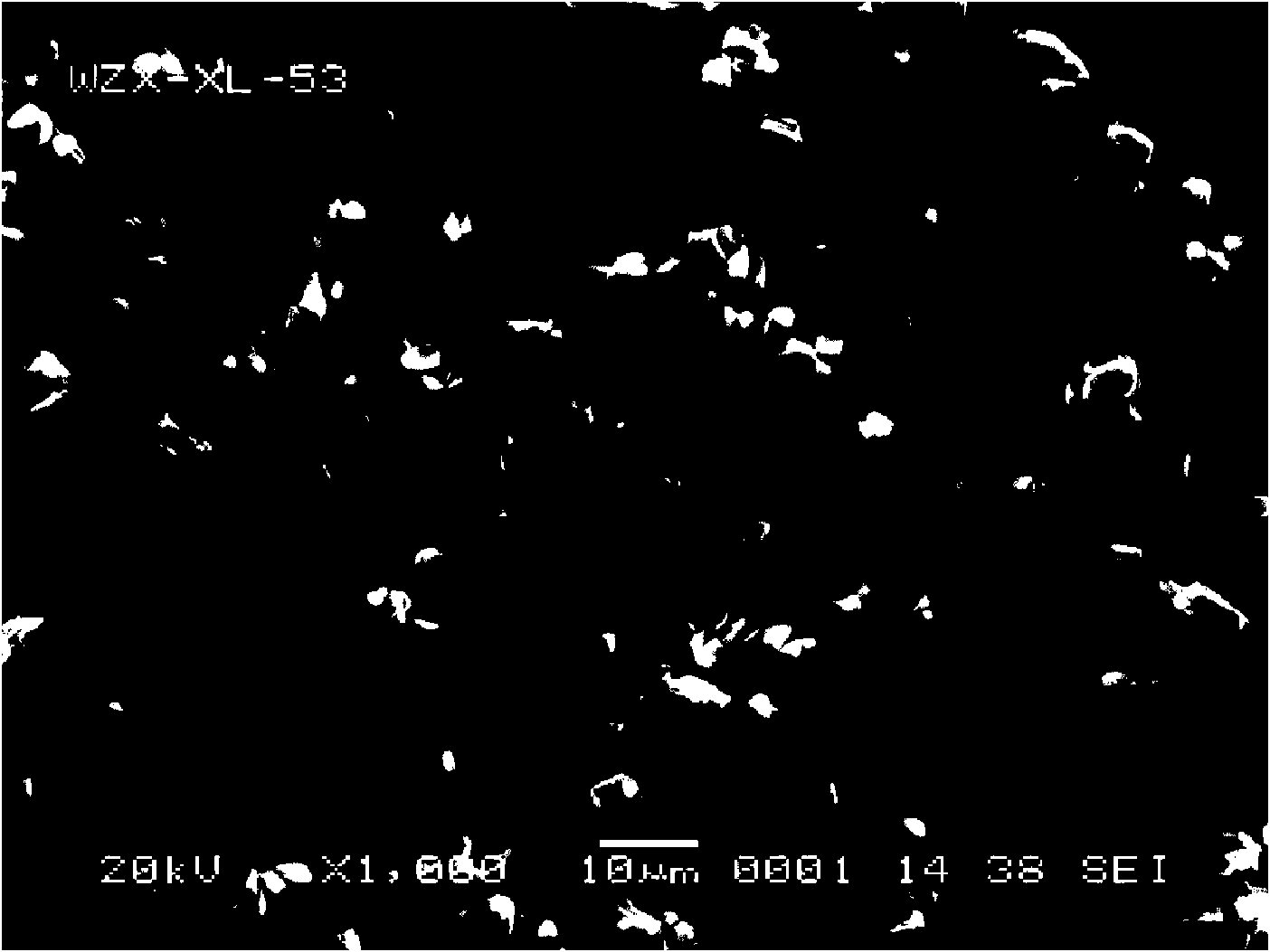

[0029] Dissolve 500g of waste paraferrous sulfate in 3L of deionized water, filter, and add 0.1mol sodium dodecylbenzenesulfonate, 0.2mol n-propanol and oxalic acid in an equimolar amount to Fe in the filtrate successively under vigorous stirring, and use Ammonia water and sulfuric acid adjust the pH of the system to 1.0, stop stirring after reacting at 40°C for 30 minutes, age at room temperature for 12 hours, then filter and wash with 30% BaCl 2 The solution detects that there is no sulfate ion, and the precipitate is dried at 80°C to obtain the precursor of lithium iron phosphate, the positive electrode material of lithium ion battery-metal element-doped ferrous oxalate, wherein Fe:Mg:Mn (molar ratio)=100: 0.4:0.2.

Embodiment 2

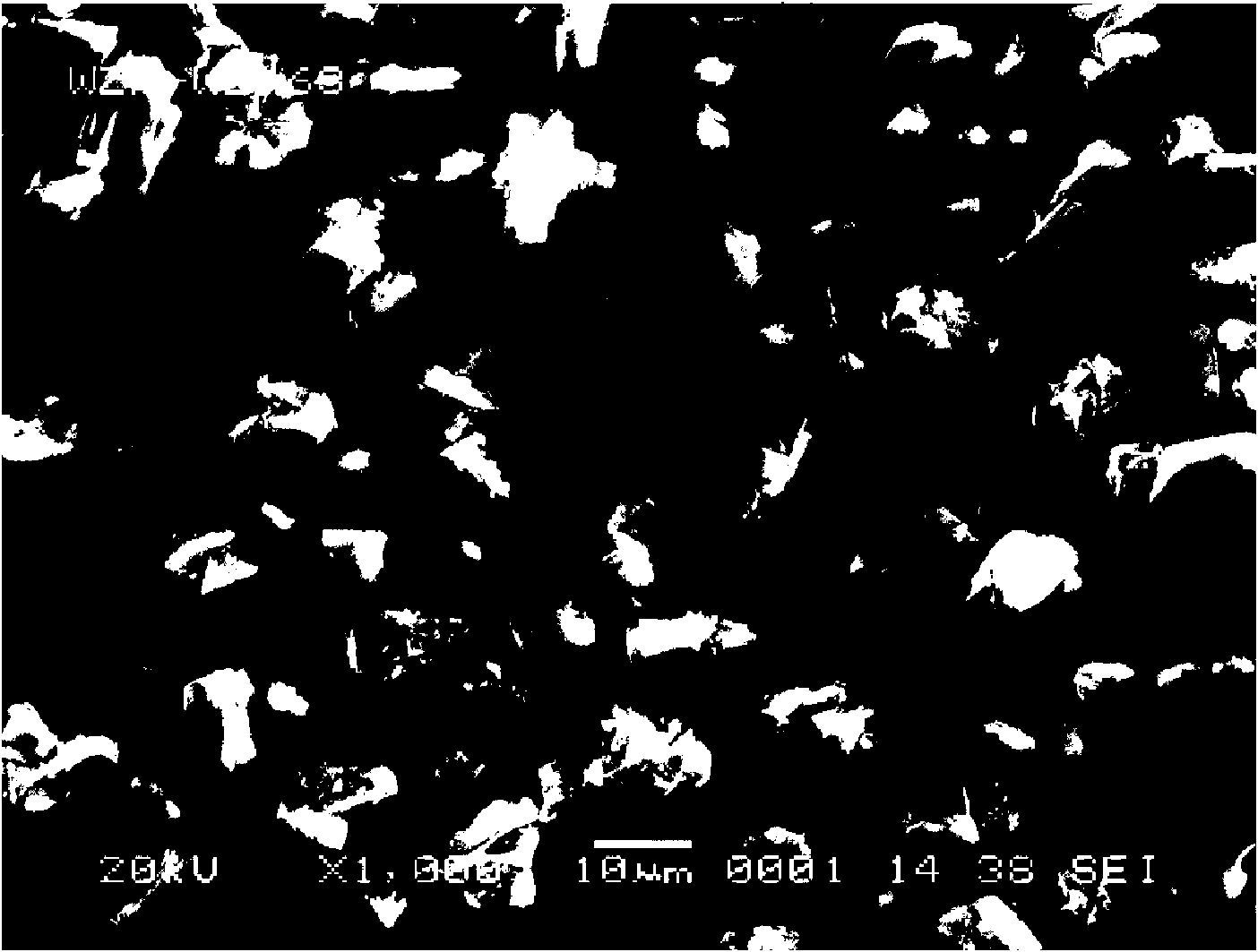

[0031]Dissolve 500 g of waste ferrous sulfate in 3 L of deionized water, filter, and add 0.05 mol of citric acid, 0.05 mol of tetraethyl glycol, 0.02 mol of triethanolamine and an equimolar amount of Fe to the filtrate successively under vigorous stirring. For ammonium oxalate, use sodium hydroxide and sulfuric acid to adjust the pH of the system to 3.0, react at 60°C for 2 hours, then stop stirring, without aging, directly filter and wash with 30% BaCl 2 The solution detects that there is no sulfate ion, and the precipitate is dried at 80° C. to obtain the precursor of the positive electrode material lithium iron phosphate for lithium-ion batteries-the ferrous oxalate doped with metal elements, wherein Fe: Mg: Al: Ca (molar ratio) = 100:0.2:0.05:0.08.

Embodiment 3

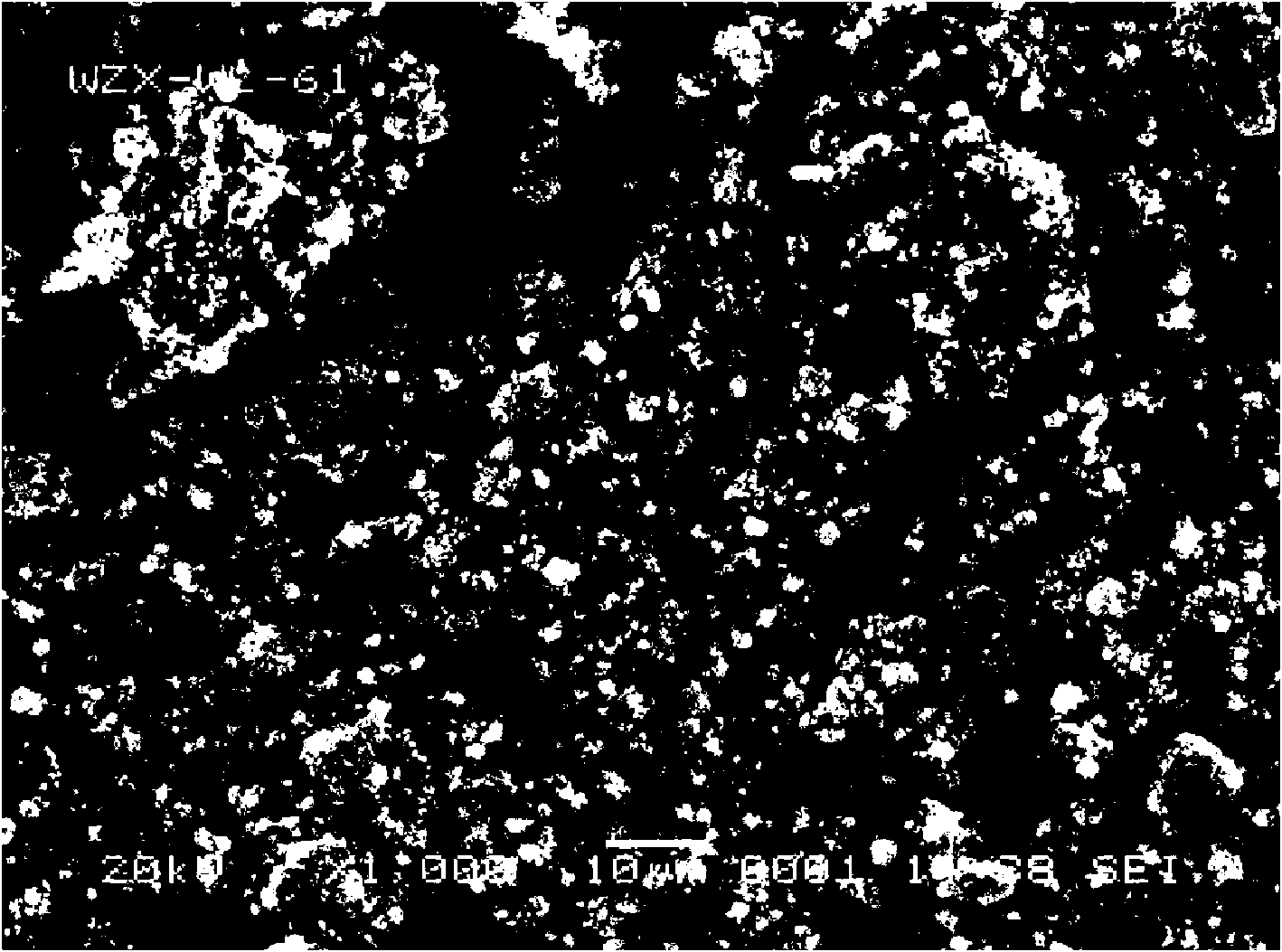

[0033] Dissolve 500g of waste ferrous sulfate in 3L of deionized water, filter, and add 0.05mol hydroxypropyl cellulose, 0.05mol sodium dodecylbenzenesulfonate, and Fe equimolar amounts to the filtrate successively under vigorous stirring. Sodium oxalate and 0.1mol humic acid, use ammonia water and oxalic acid to adjust the pH of the system to 5.0, stop stirring after reacting at 20°C for 5 minutes, age at room temperature for 24 hours, then filter and wash with 30% BaCl 2 The solution detects that there is no sulfate ion, and the precipitate is dried at 80° C. to obtain the precursor of the positive electrode material lithium iron phosphate for lithium-ion batteries-the ferrous oxalate doped with metal elements, wherein Fe: Mg: Al: Ti (molar ratio) = 100:1.2:0.03:0.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com