Aztreonam for injection and production method thereof

A technology for aztreonam and injection, which is applied in the field of aztreonam for injection, and can solve the problems that aztreonam and L-arginine cannot be fully contacted and protected, inconsistent stability, loss of organic solvent, etc., and achieve stability Consistent, small packaging differences, and the effect of reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Implementation example 1 injection aztreonam arginine production method

[0045] Investigation of Solubility and pH

[0046] Prepare a series of mixed powders according to the following prescription, dissolve them in 10ml of water, observe their appearance to check the solubility of the mixed powders; measure their pH value to check the acidity and alkalinity of the mixed powders. Referring to the standard of injection, its aqueous solution should be clear without turbidity, and the pH value should be 4.5-7.5. see results

[0047] The investigation of table 1 acidity and alkalinity

[0048]

[0049] It can be seen that the amount of L-arginine is lower than 5% of the prescription amount, which cannot improve the solubility of aztreonam; therefore, the amount of arginine should be within the range of -5% to +10% of the labeled amount, β Preferably, the weight ratio of crystalline aztreonam to L-arginine is 1 / 0.74 to 1 / 0.86.

[0050] Bulk Density Inspection

[005...

Embodiment 2

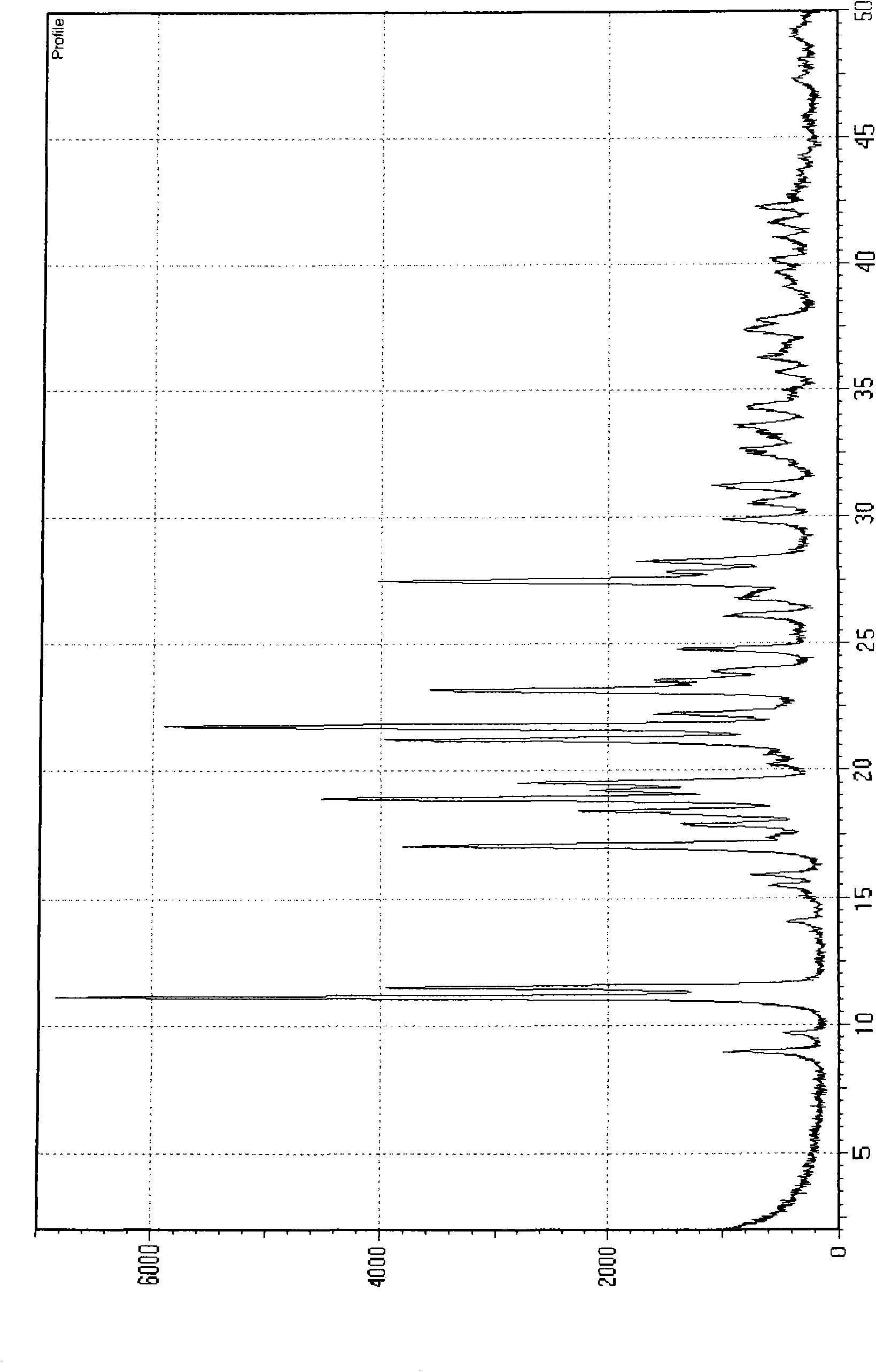

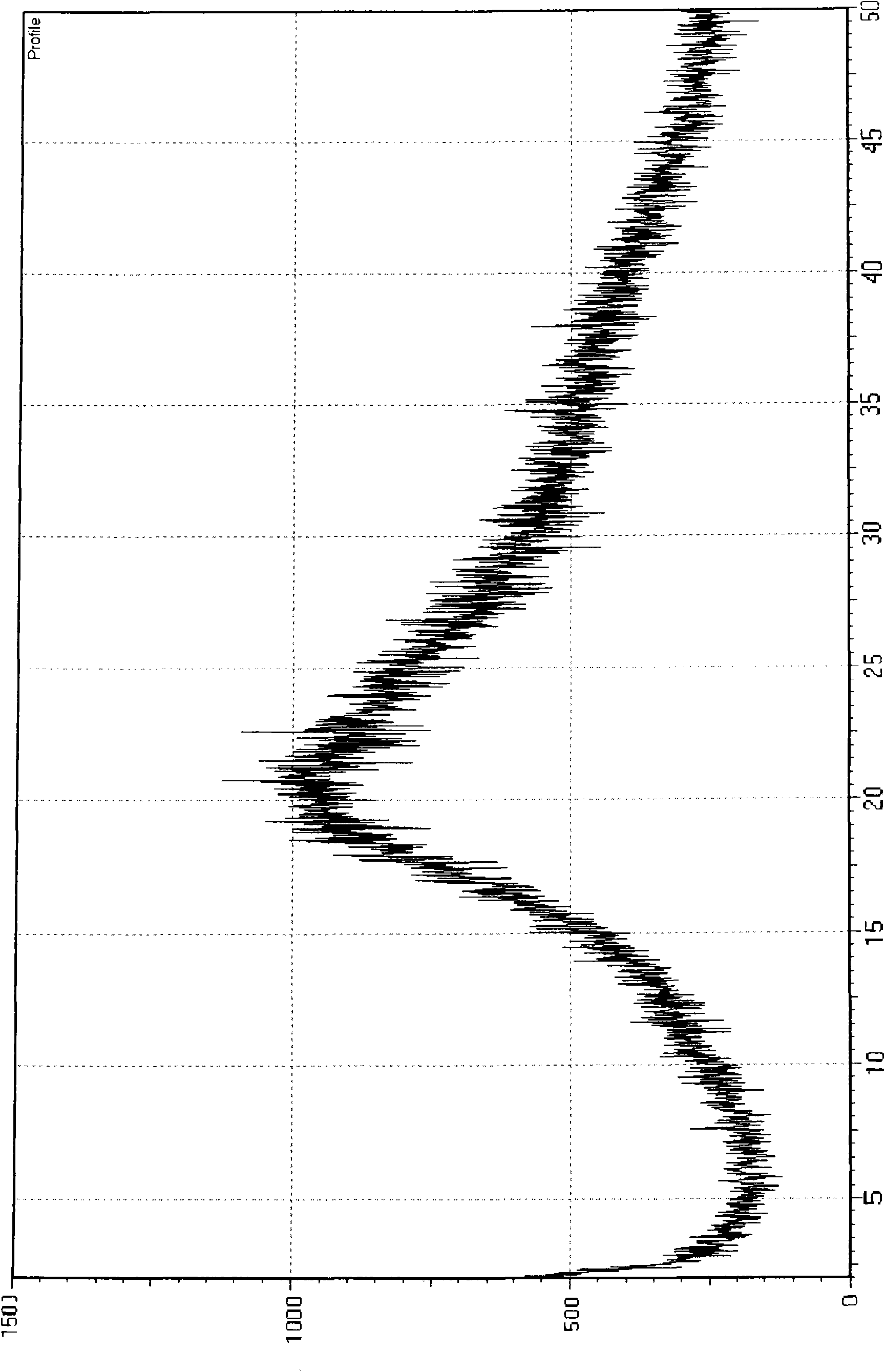

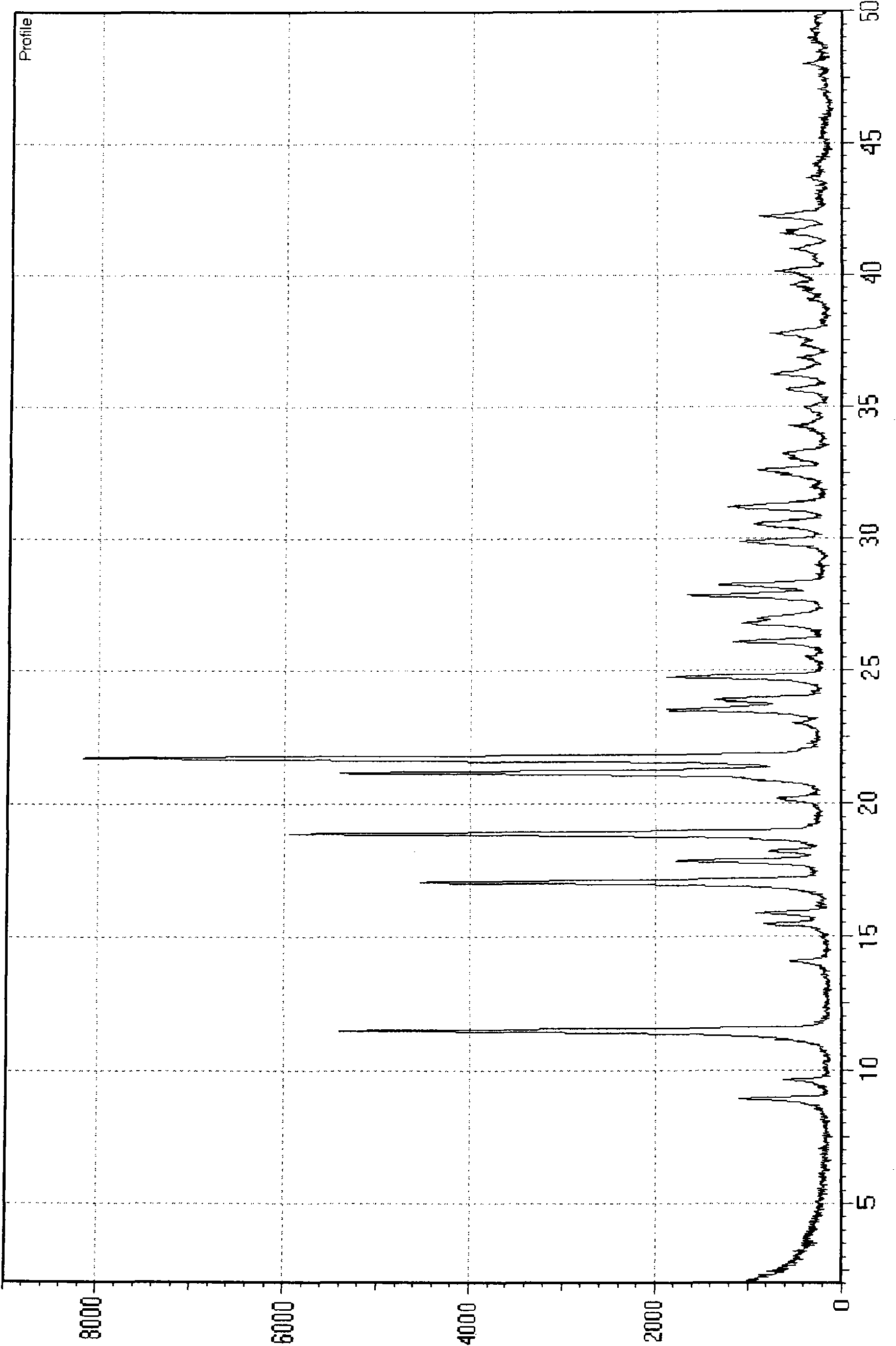

[0069] Embodiment 2 crystal forms compare

[0070] Adopt X-powder diffraction to study reconstituted freeze-dried injection aztreonam (arginine), aztreonam raw material, and the injection aztreonam (arginine) that adopts above-mentioned method to produce, the result shows that aztreonam Raw material, and the aztreonam for injection (arginine) that adopts said method to produce, its X-ray powder diffraction characteristic peak is basically identical, is beta crystal form; And the aztreonam for injection ( arginine), the X-powder derived characteristic peaks disappear, and it is an amorphous powder.

Embodiment 3

[0071] Aztreonam for injection (arginine) loading difference and arginine content comparison of implementation example 3 different production methods

[0072] Production method of aztreonam freeze-dried powder and aztreonam directly subpackaged powder

[0073] method 1 : Take 1kg of aztreonam and 0.78kg of arginine calculated by deducting water, add 10000ml of water to dissolve, measure the pH of the solution, adjust the pH to 6.0 with arginine, add activated carbon according to the amount of 0.2%, at a lower temperature Stir at low temperature for 15 minutes, coarsely filter out the activated carbon, perform sterile filtration with a 0.22um microporous membrane, freeze-dry the filtrate, and put the dried powder directly into vials, stopper and seal with an aluminum cap to obtain .

[0074] Method 2 : Weigh aztreonam and L-arginine according to the prescription amount, mix them in a mixer for 30 minutes until uniform, measure the pH value and content, after passing the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com