Sulfenyl anode of lithium-sulfur rechargeable battery and preparation method thereof

A lithium-sulfur battery, sulfur-based technology, applied in the direction of secondary batteries, electrode manufacturing, active material electrodes, etc., can solve the problem of unsatisfactory electrode cycle stability, achieve good cycle stability, improve charge-discharge cycle performance, prevent The effect of electrode self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of sulfur-based composite active materials for secondary lithium-sulfur batteries:

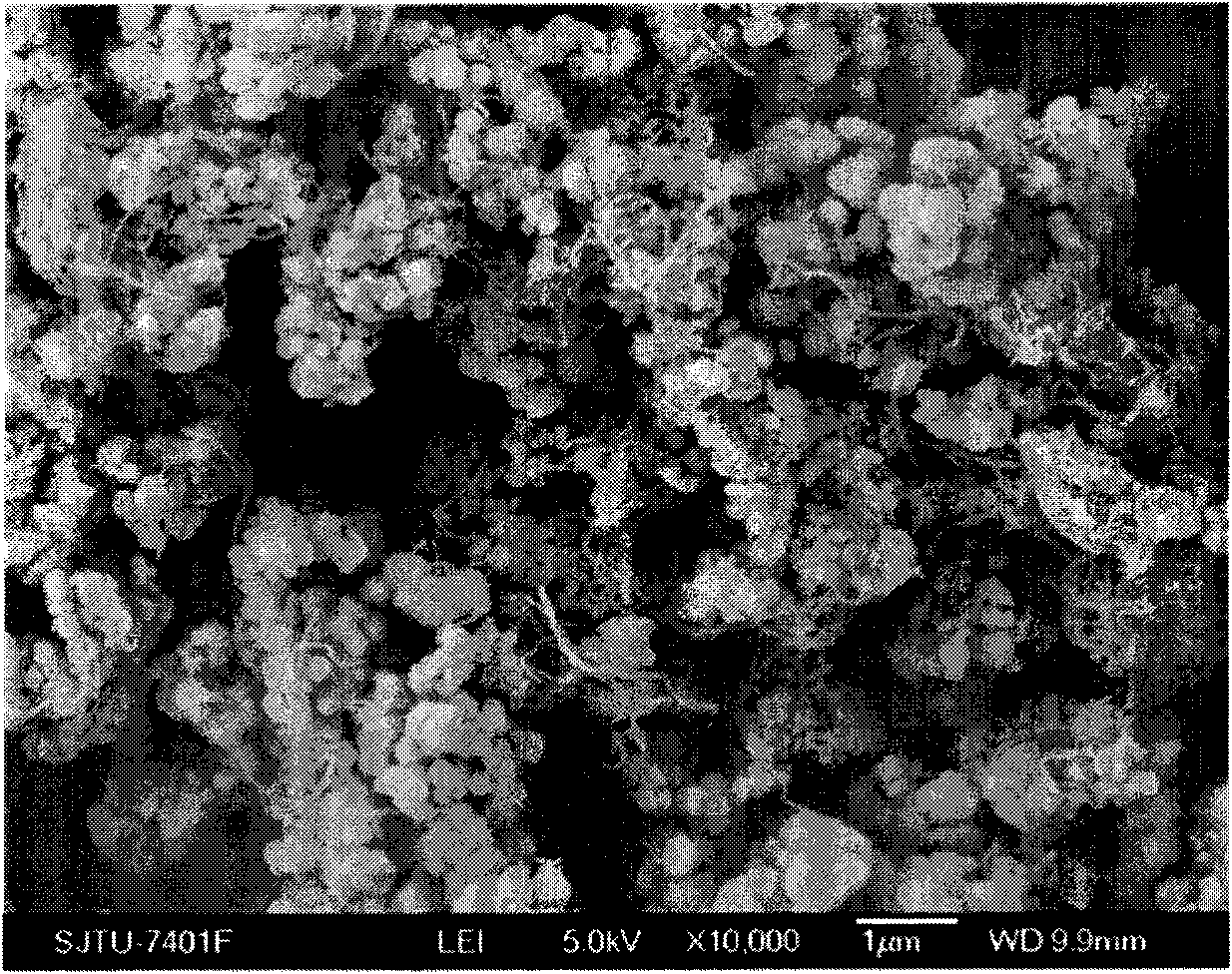

[0033] Mix 0.1g of carbon nanotubes, 6g of elemental sulfur and 1g of polyacrylonitrile, add 0.2g of absolute ethanol as a dispersant, place in an agate ball mill jar equipped with an O-ring, put in agate beads, and start ball milling. The speed of the high-energy ball mill is 250 rpm, and the ball milling time is 2 hours to obtain a uniformly dispersed carbon nanotube / elemental sulfur / polyacrylonitrile mixture; the mixture is transferred from the agate ball mill jar to a quartz boat, and vacuum-dried at 80°C After 2 hours, the dispersant absolute ethanol was removed to obtain a dry carbon nanotube / elemental sulfur / polyacrylonitrile mixture of about 6.83g; the quartz boat with the dry mixture was put into a clean quartz tube, Under the protection of an inert gas, it was kept at 320° C. for 7 hours to obtain 1.74 g of sulfur-based composite active material.

[0034] figure ...

Embodiment 2

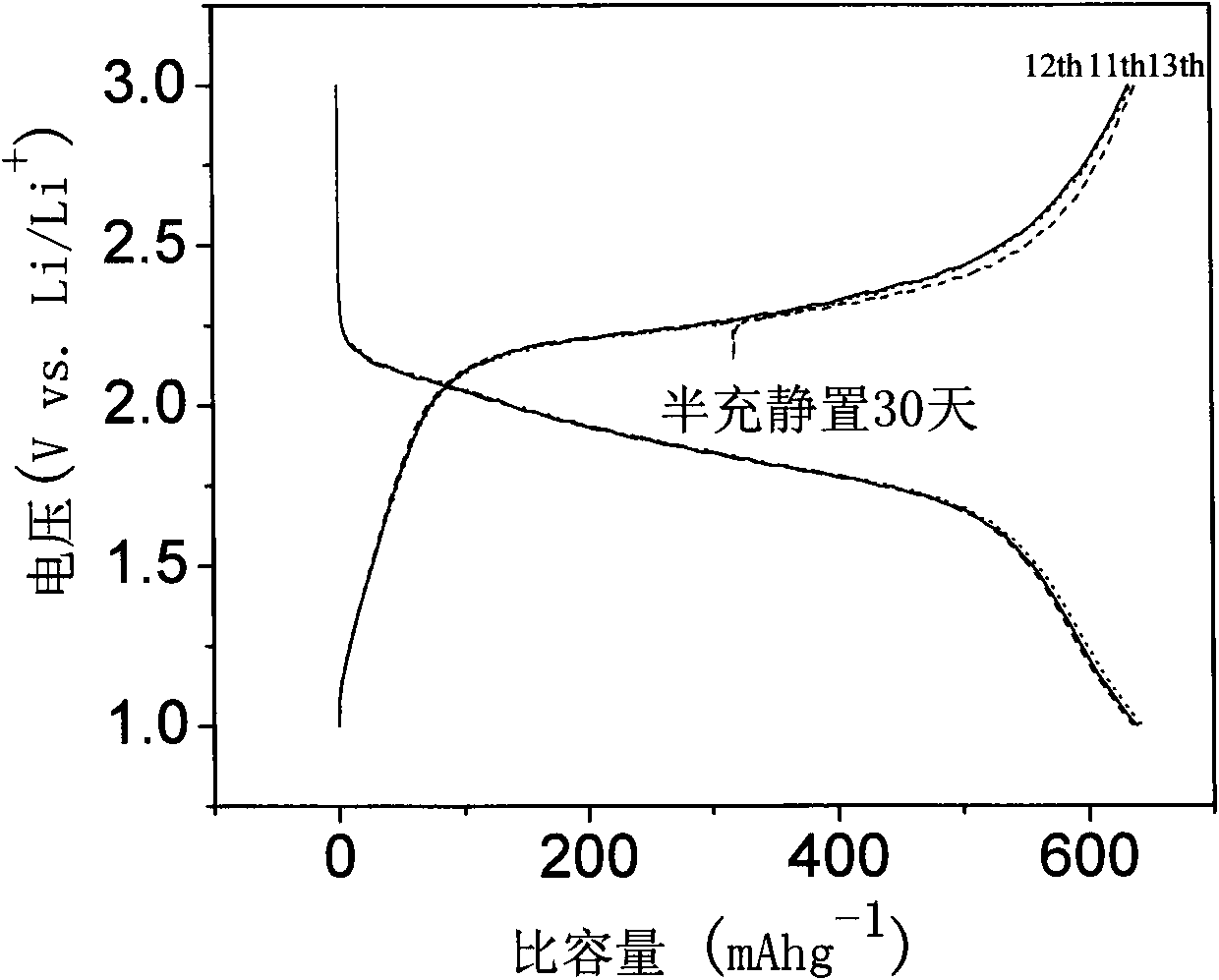

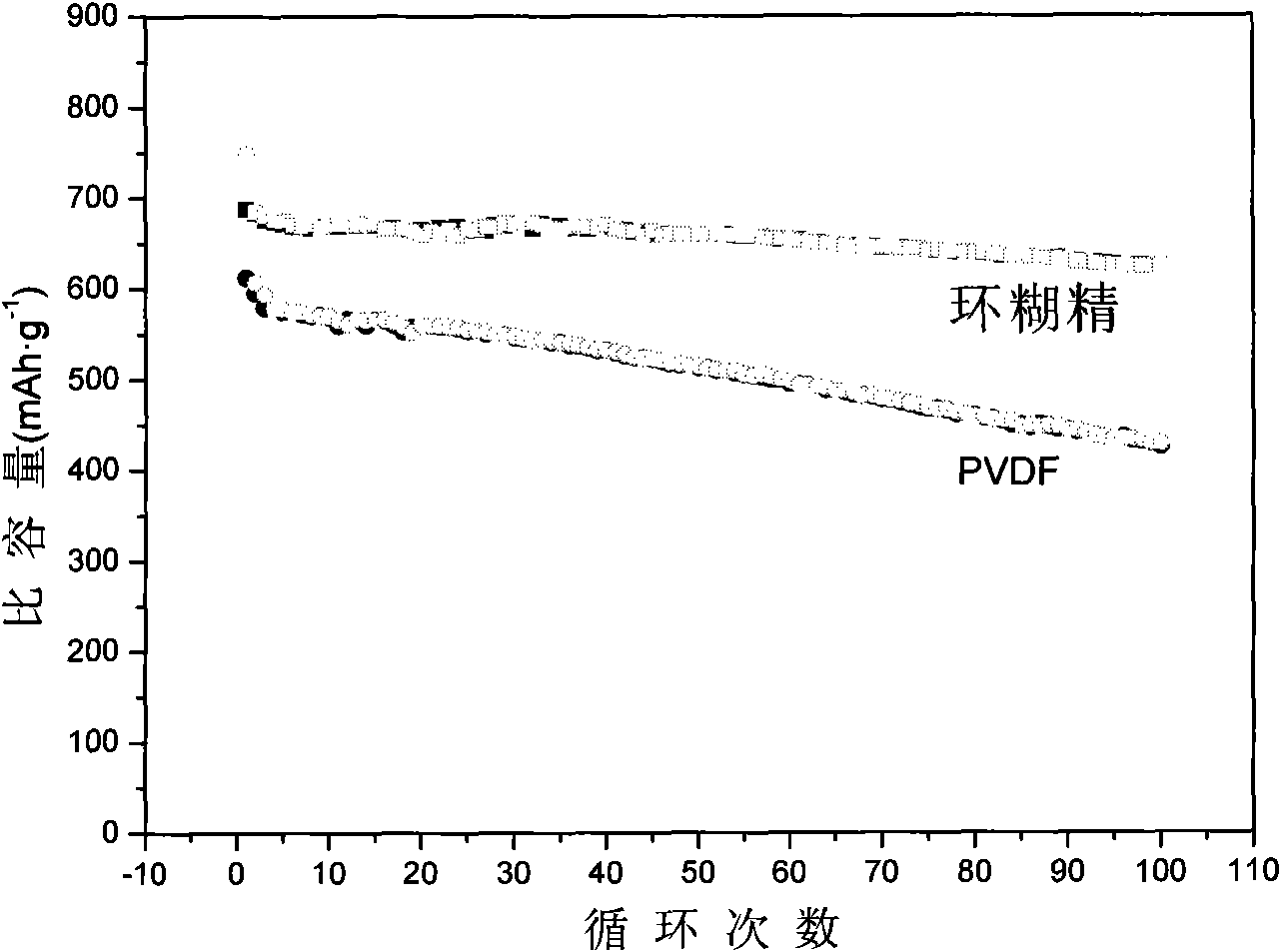

[0037] The sulfur-based composite active material for the secondary lithium-sulfur battery obtained in Example 1 was used as the active material, β-cyclodextrin was used as the binder, and Super P carbon black was used as the carbon conductive agent. Put 10mg of β-cyclodextrin and 3mL of distilled water in a mixing cup, heat to 40°C to dissolve the β-cyclodextrin in water to form a colorless solution, then add 10mg of Super P carbon black conductive agent and 80mg of Sulfur-based composite active material, followed by ultrasonic treatment for 30 minutes, the ultrasonic frequency is 100kHz, and then kept at 40°C and magnetically stirred for 3 hours, and the uniformly mixed slurry was coated on aluminum foil, and vacuum-dried at 80°C for 2 hours. After tableting under pressure, a sulfur-based positive electrode of a secondary lithium-sulfur battery using β-cyclodextrin as a binder is obtained.

[0038] The prepared sulfur-based positive electrode was punched into pole pieces wit...

Embodiment 3

[0042] The sulfur-based composite active material for the secondary lithium-sulfur battery obtained in Example 1 was used as the active material, β-cyclodextrin was used as the binder, and Super P carbon black was used as the carbon conductive agent. Put 8mg of β-cyclodextrin and 3mL of distilled water in a mixing cup, heat to 40°C to dissolve the β-cyclodextrin in water to form a colorless solution, then add 8mg of Super P carbon black conductive agent and 84mg of Sulfur-based composite active material, followed by ultrasonic treatment for 30 minutes, the ultrasonic frequency is 100kHz, and then kept at 40°C and magnetically stirred for 4 hours, and the obtained uniformly mixed slurry was coated on an aluminum foil, and vacuum-dried at 80°C for 2 hours. After tableting under a pressure of 2 MPa, a sulfur-based positive electrode of a secondary lithium-sulfur battery with β-cyclodextrin as a binder is obtained.

[0043] The prepared sulfur-based positive electrode was punched ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com