Method for analyzing and detecting alloying elements in beryllium-aluminum alloy

A technology of beryllium aluminum alloy and detection method, which is applied in the field of analysis and detection, can solve the problems of easy volatilization of germanium element, influence of analysis and detection, etc., and achieves the effects of good reproducibility, less interference and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

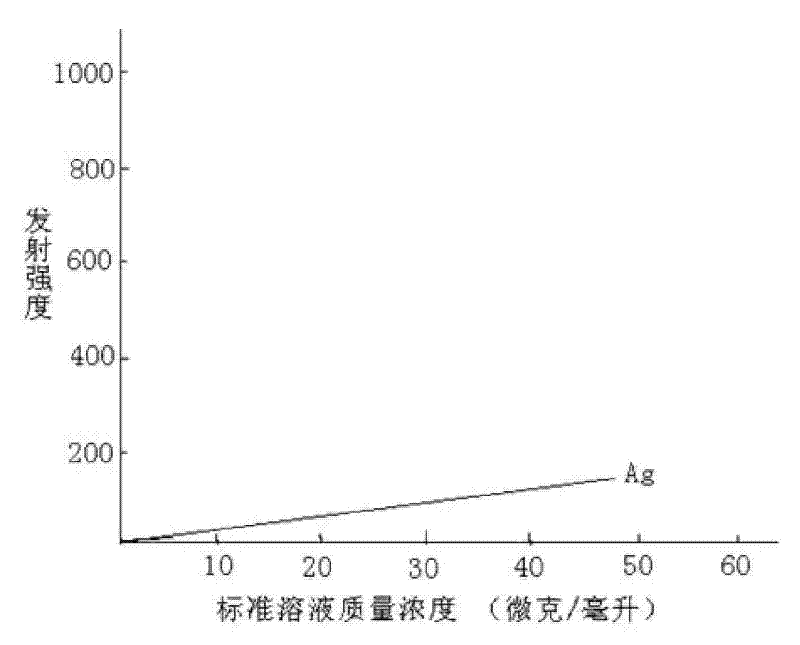

[0041] Determination of silver element

[0042] Step 1: Prepare the sample solution containing silver beryllium aluminum alloy to be tested

[0043] Weigh 0.1 g of the silver-beryllium aluminum alloy sample to be tested and 5 ml of 20% sodium hydroxide solution, place it in a polytetrafluoroethylene plastic beaker, and dissolve it at low temperature. After the silver-beryllium aluminum alloy sample to be tested is completely decomposed , add a small amount of 30% hydrogen peroxide dropwise for oxidation, heat and decompose excess hydrogen peroxide after oxidation, cool to obtain a mixed solution, add 30 milliliters of 50% hydrochloric acid and 10 milliliters of 50% nitric acid, after acidification Transfer to a glass beaker, heat until the solution is completely clear, transfer it to a volumetric flask after cooling, dilute to 100 ml with water, and shake well to obtain a sample solution containing silver beryllium aluminum alloy to be tested;

[0044] Step 2: Draw a standard...

Embodiment 2

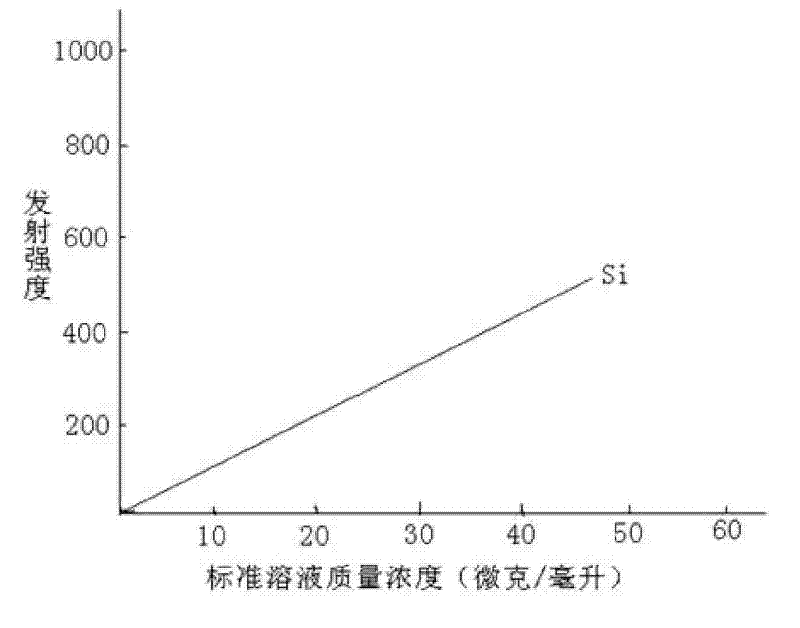

[0063] Determination of silicon element

[0064] Step 1: Prepare the sample solution containing silicon beryllium aluminum alloy to be tested

[0065] Weigh 0.1 gram of the silicon-containing beryllium aluminum alloy sample to be tested and 3 ml of 20% sodium hydroxide solution, place it in a polytetrafluoroethylene plastic beaker, and dissolve it at low temperature. After the silicon-beryllium aluminum alloy sample to be tested is completely decomposed , add a small amount of 30% hydrogen peroxide dropwise for oxidation, heat and decompose excess hydrogen peroxide after oxidation, cool to obtain a mixed solution, add 50 ml of 50% hydrochloric acid and 20 ml of 50% nitric acid, after acidification Transfer to a glass beaker, heat until the solution is completely clear, transfer it to a volumetric flask after cooling, dilute to 100 ml with water, and shake well to obtain a sample solution containing silicon beryllium aluminum alloy to be tested;

[0066] Step 2: Draw a standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com