Special-shaped gear with inner shaping layer and machining process thereof

A special-shaped gear and shaping layer technology, applied in the direction of components with teeth, belts/chains/gears, gear lubrication/cooling, etc. problem, to reduce wear and ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

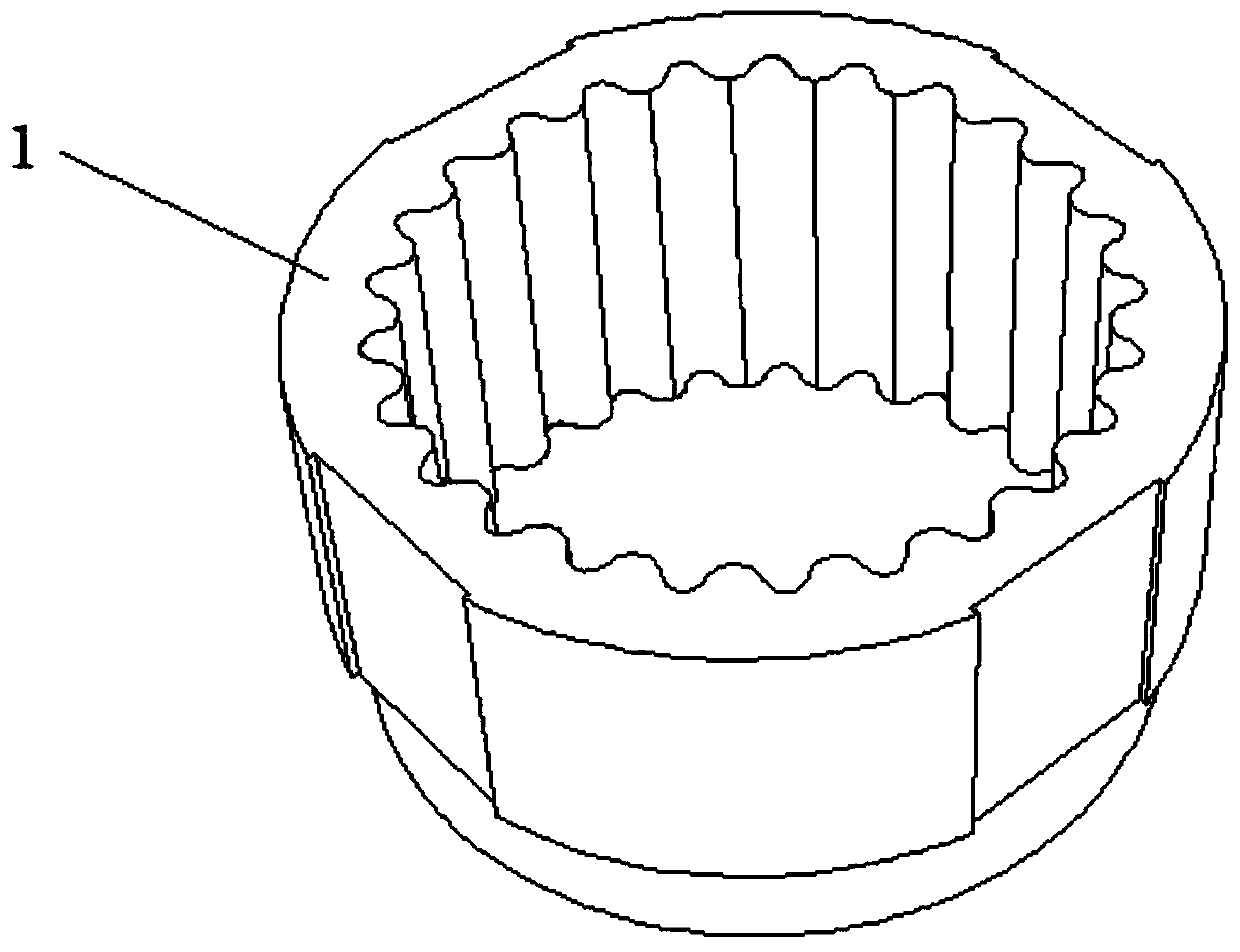

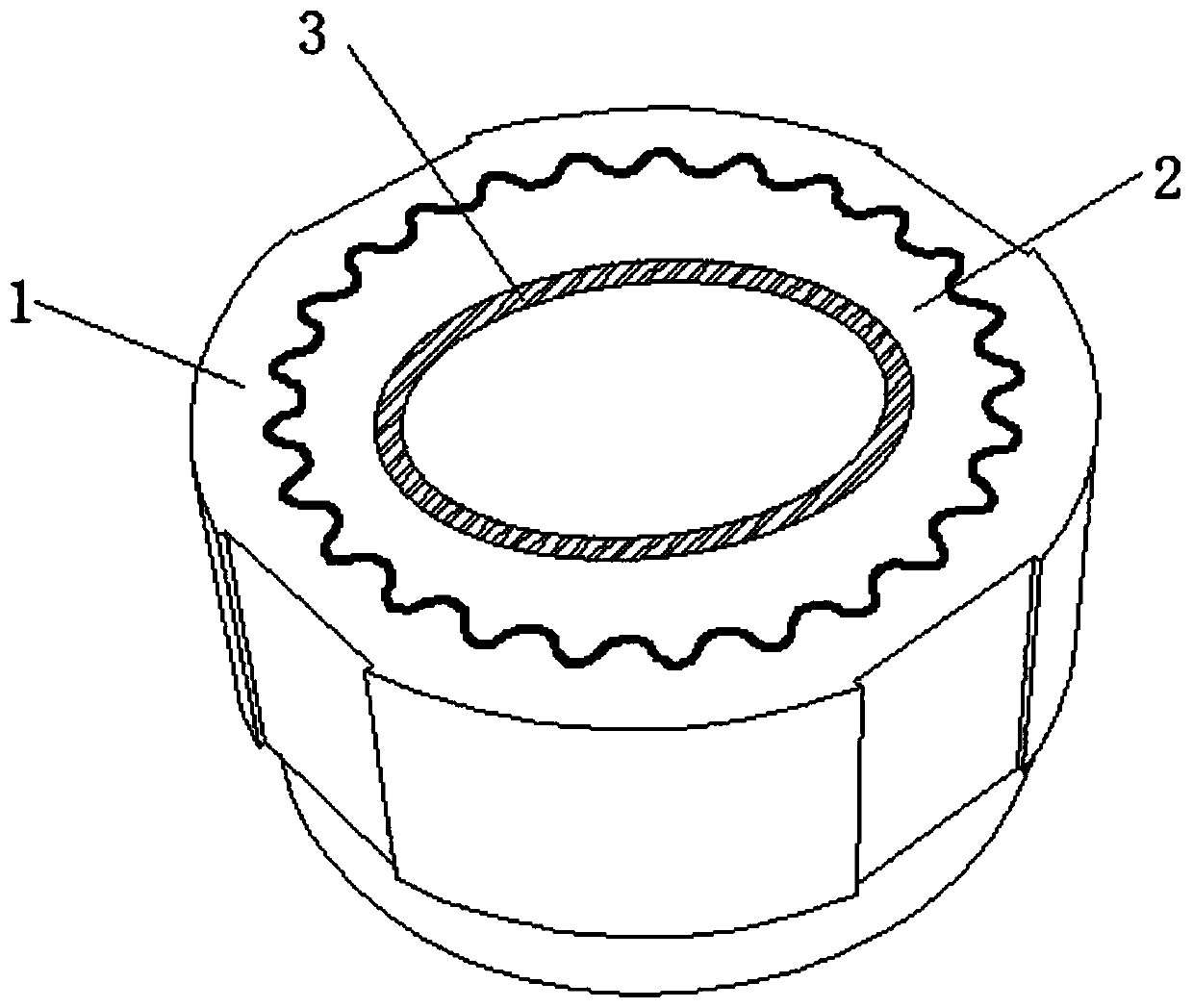

[0050] see figure 1 with figure 2 , a special-shaped gear with an internal shaping layer, including a special-shaped gear body 1, the teeth of the special-shaped gear body 1 are located on the inner ring of the special-shaped gear body 1, please refer to image 3 , the inside of the special-shaped gear body 1 is provided with a self-fitting tooth surface tube. The self-fitting tooth surface tube includes a self-fitting tube 2 and a reinforcing and fixing tube 3, and the reinforcing and fixing tube 3 is located inside the self-fitting tube 2. Please refer to Figure 5 with Image 6 , the outer end of the self-fitting tube 2 is wrapped with a self-lubricating ring and a selectively permeable film layer 4, the self-lubricating ring is located at one end of the self-fitting tube 2, and the selectively permeable film layer 4 is located outside the self-lubricating ring, A plurality of tiny oil pockets 7 are arranged between the selectively permeable membrane layer 4 and the sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com