Catalyst protective agent and preparation method thereof

A protective agent and catalyst technology, applied in the field of preparation of the protective agent, can solve the problems of main catalyst poisoning, main catalyst activity decrease, pressure drop increase, etc., achieve good demetallization and decarbonization performance, protection activity stability, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

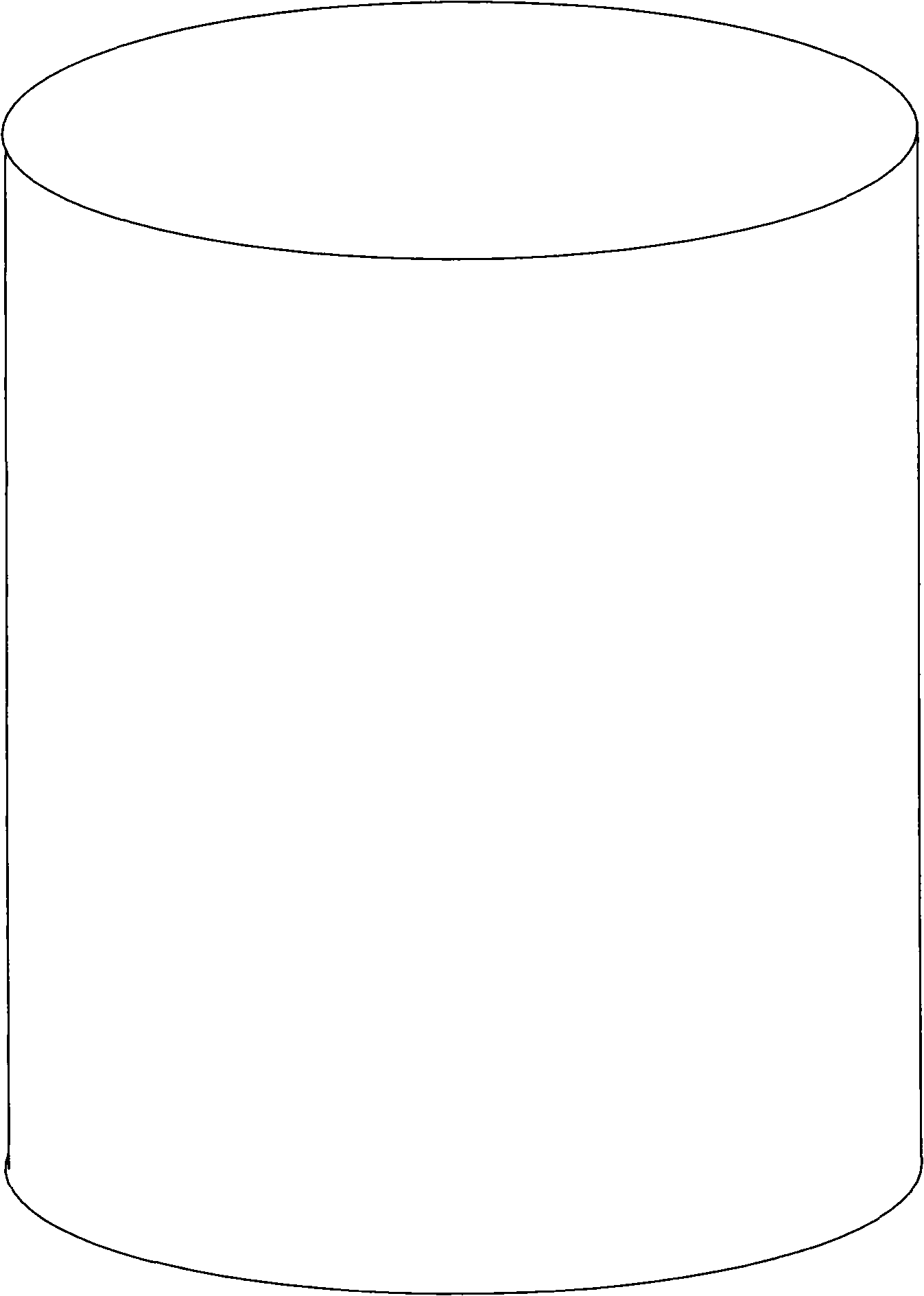

[0025] Add appropriate amount of pore-enlarging agent, pore volume agent and high-efficiency binder to 90% carrier component powder, and form a muddy slurry with good plasticity after rolling and kneading; use a piston or a screw to force the above-mentioned muddy slurry through the pores board, cut into strip-shaped cylinders of almost equal length and diameter, dried and calcined to obtain a semi-finished product; then use the co-precipitation method to soak the above semi-finished product in nickel nitrate and molybdenum nitrate solution to obtain a finished product within a predetermined content range , wherein the content of the active component NiO at this time is 0.8%, and the active component MoO 3 The content of the catalyst protection agent of the present invention is 1.0%, which can be obtained by drying.

Embodiment 2

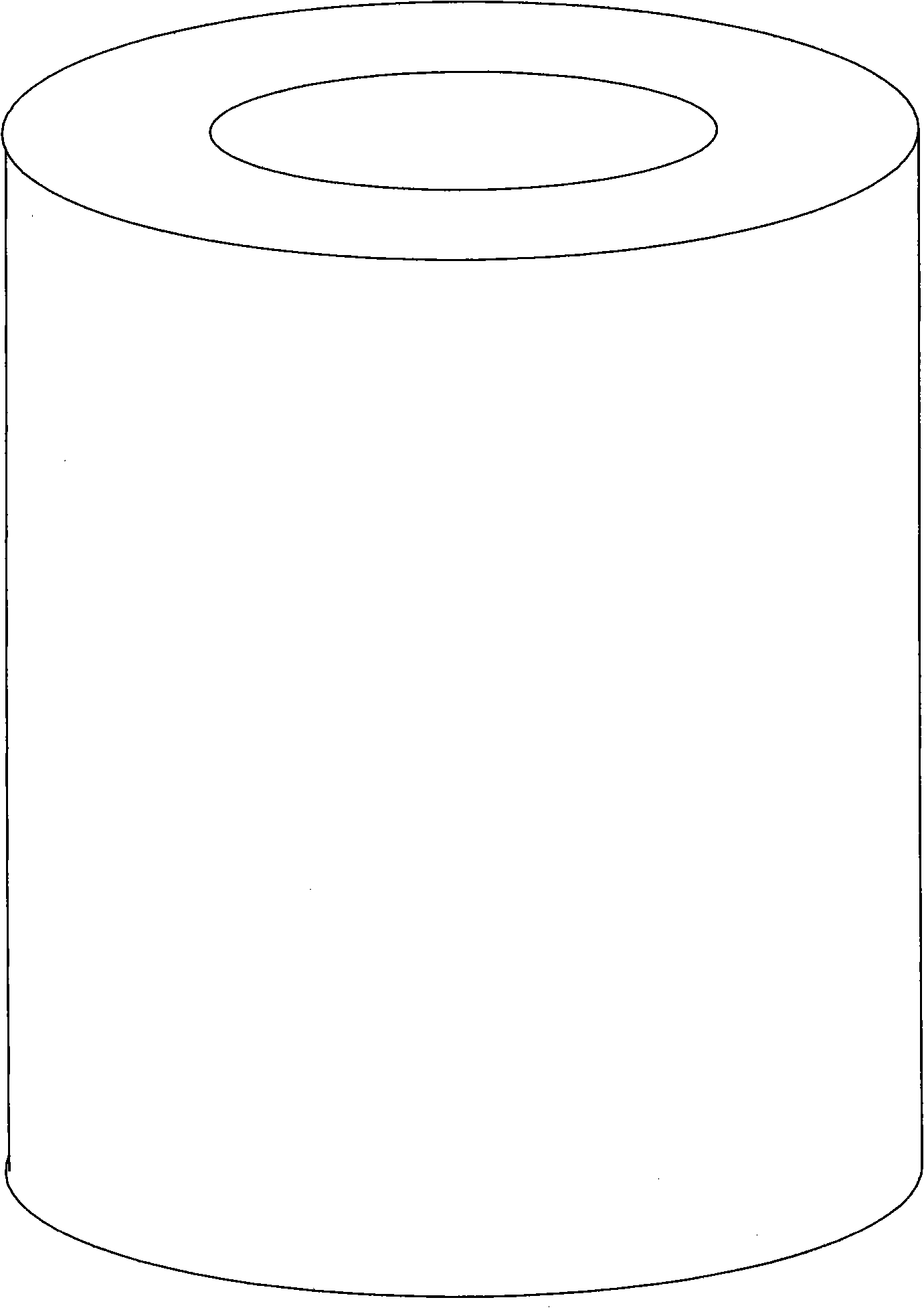

[0027] Add 98.2% of the carrier component powder to an appropriate amount of pore-enlarging agent, pore volume agent and high-efficiency binder, and form a mud-like slurry with good plasticity after rolling and kneading; use a piston or a screw to force the above-mentioned mud-like slurry through the pores board, cut into almost equal-length and equal-diameter strip-shaped ring cylinders, dried and calcined to obtain the semi-finished product; then use the co-precipitation method to soak the above-mentioned semi-finished product in nickel nitrate and molybdenum nitrate solution to obtain the predetermined content range. Finished product, wherein the content of the active component NiO at this time is 1.2%, the active component MoO 3 The content is 1.5%, drying can wait until the catalyst protection agent of the present invention.

Embodiment 3

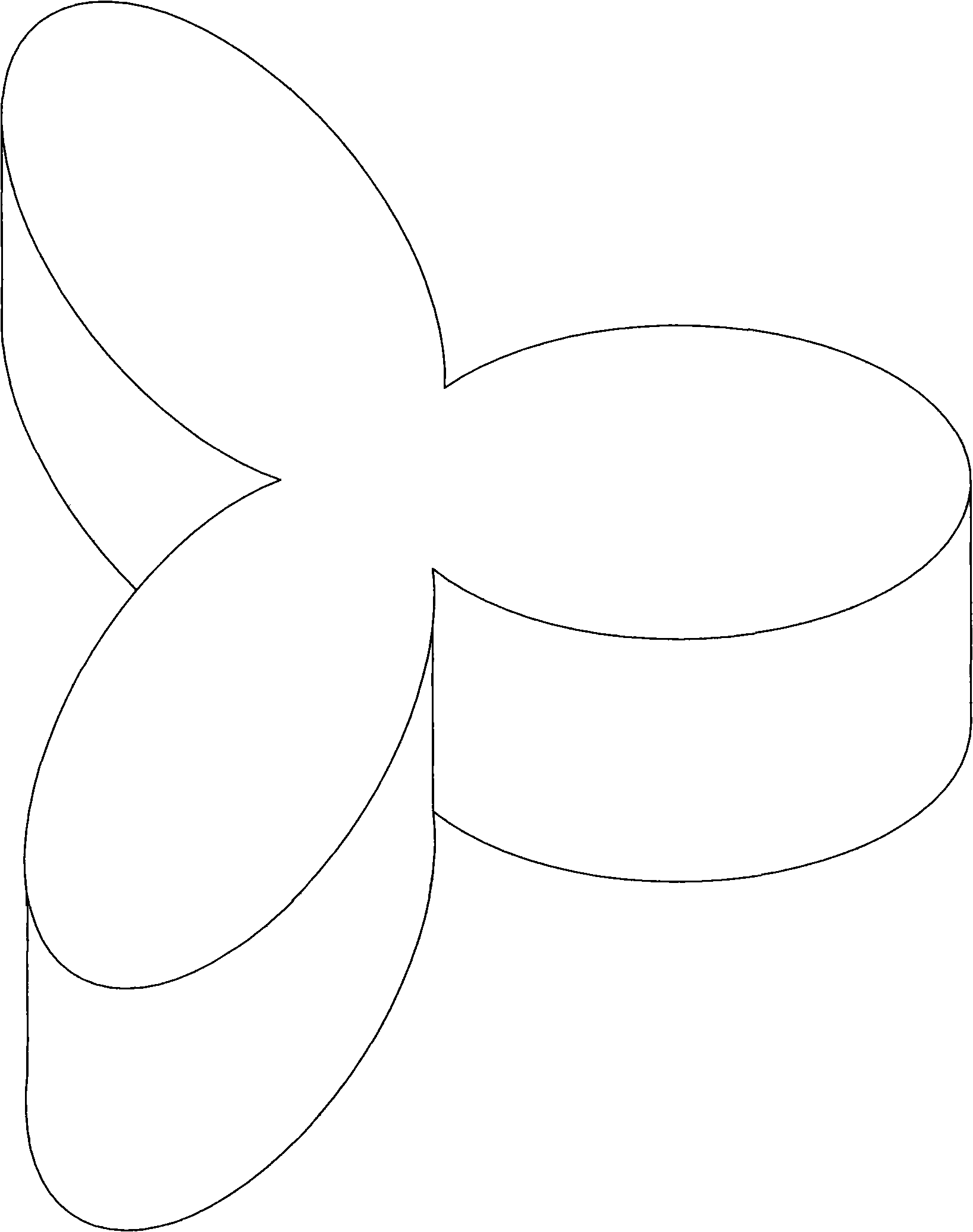

[0029] Add appropriate amount of pore-enlarging agent, pore volume agent and high-efficiency binder to 95% carrier component powder, and form a muddy slurry with good plasticity after rolling and kneading; use a piston or a screw to force the above-mentioned muddy slurry through the pores board, cut into strip-shaped clover with almost equal length and equal diameter, dried and calcined to obtain the semi-finished product; then use the co-precipitation method to soak the above semi-finished product in nickel nitrate and molybdenum nitrate solution to obtain the finished product within the predetermined content range, Wherein at this moment the content of active component NiO is 1.0%, active component MoO 3 The content is 1.2%, drying can wait until the catalyst protection agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com