Amorphous soft magnetic alloy and inductance component using the same

A technology of soft magnetic alloy and soft magnetic alloy strip, which is applied in the fields of components and components, strips, strips, and powders, and can solve the problems of low content of iron-based elements, insufficient ability to form amorphous components, and weakened soft magnetic properties, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0082] The present invention will be described in detail below with examples.

[0083] (Examples 1 to 15)

[0084] Weigh the pure metal materials Fe, P, B, Al, V, Cr, Y, Zr, Nb, Mo, Ta and W according to the predetermined alloy composition, and then carry out high It is melted by frequent heating to obtain a master alloy. Thereafter, using the prepared master alloys, strips having thicknesses of 20 μm and 200 μm, respectively, were produced using a single roll method by adjusting the rotational speed.

[0085] For comparison, a master alloy having the same composition as commercial METGLAS 2605-S2 was prepared by high-frequency heating, and then 20 μm and 200 μm strips were formed by a single-roll method.

[0086]For each strip of 200 μm, use the X-ray diffraction method to measure the slowest cooling free solidification surface that is not in contact with the copper roll, thereby obtaining the X-ray diffraction test pattern, when the obtained X-ray diffraction test pattern ...

example 133

[0150] In example 133, the composition is Fe 77 P 10 B 10 Nb 2 Cr 1 Ti 0.1 C 0.1 mn 0.1 Cu 0.1 The alloy powder obtained was then classified into a particle size of 45 μm or less, which was then subjected to XRD measurements, after which a broad peak dedicated to the amorphous phase was identified. In addition, thermal analysis was performed by DSC to measure glass transition temperature (Tg) and crystallization temperature (Tx), whereby ΔTx (Tg-Tx) was determined to be 36°C. Then, the powder was kept at a temperature of 400° C. lower than the glass transition temperature to undergo heat treatment in the atmosphere for 0.5 hours, thereby forming oxides on the surface of the powder.

[0151] In addition, a silicone resin as a binder was added to the oxide-formed powder in an amount of 5%, 2.5%, 1% and 0.5%, respectively, to obtain respective powders. Using pressed parts with grooves with an outer diameter of 27 mm and an inner diameter of 14 mm, at room temperature, at...

example 134

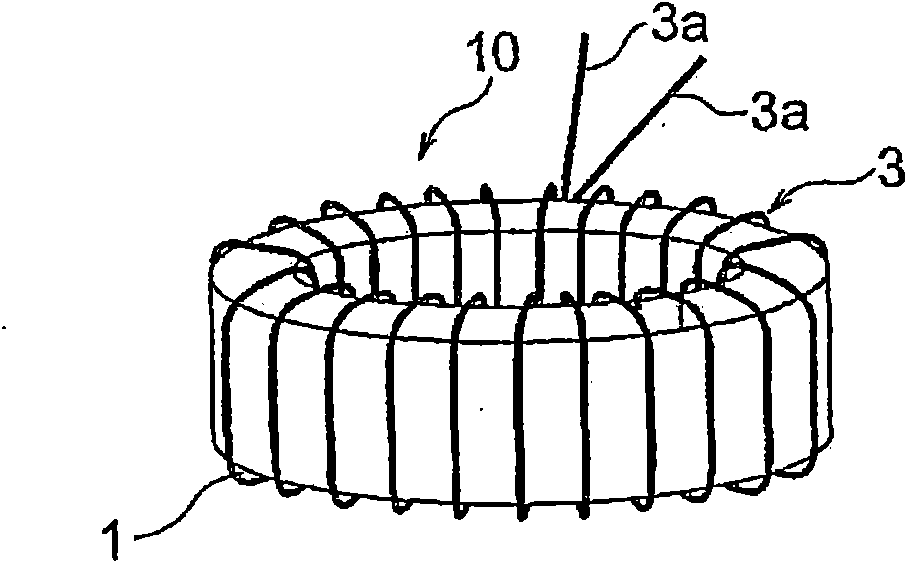

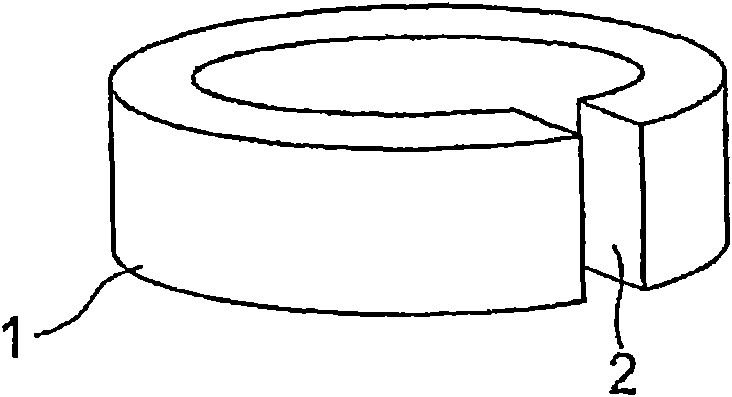

[0156] In Example 134, an inductance component corresponding to the 10th sample in Example 133 was produced using the same alloy powder and the same manufacturing process and heat treatment at 450°C for 0.5 hours in a nitrogen atmosphere. High-frequency magnetic cores are used to manufacture inductive components. In addition, for comparison, an inductance part was fabricated using sendust powder as a magnetic core material, 6.5% silicon steel, and an Fe-based amorphous material. Each inductive component is as figure 2 shown, but can also be Figure 4 Inductive component shown with a notch in part of the magnetic path. For each of these inductive components, the magnetic flux density (at 1.6×10 4 A / m), DC resistivity (Ω·cm), permeability for inductance normalization, and core loss (20kHz 0.1T) are measured. The results are shown in Table 15.

[0157] It can be understood from Table 15 that the magnetic flux density of the inductance part of the present invention is substa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com