Amorphous soft magnetic alloy and inductance component using the same

A soft magnetic alloy and amorphous technology, which is applied in the field of powder, components and parts, strip, and strip, can solve the problems of low content of iron-based elements, high heat treatment temperature, difficult powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0081] The present invention will be explained in detail below by way of examples.

[0082] (Examples 1 to 15)

[0083] The pure metal materials Fe, P, B, Al, V, Cr, Y, Zr, Nb, Mo, Ta and W were weighed respectively according to the predetermined alloy composition, and then the high It is melted by frequent heating, thereby producing a master alloy. After that, using the prepared master alloy, strips having thicknesses of 20 μm and 200 μm, respectively, were prepared by adjusting the rotation speed using a single roll method.

[0084] For comparison, a master alloy with the same composition as commercial METGLAS 2605-S2 was produced by high frequency heating, and then 20 μm and 200 μm strips were formed using a single roll method.

[0085] For each 200μm strip, the X-ray diffraction method was used to measure the slowest cooling free solidification surface not in contact with the copper roll, thereby obtaining an X-ray diffraction test pattern. When the obtained X-ray diffra...

example 133

[0149] In Example 133, a water atomization method was used to obtain Fe with a composition of 77 P 10 B 10 Nb 2 Cr 1 Ti0.1 C 0.1 Mn 0.1 Cu 0.1 The resulting alloy powder was then classified into a particle size of 45 μm or less, and then subjected to XRD measurement, after which a broad peak specific to the amorphous phase was determined. In addition, thermal analysis was performed by DSC to measure glass transition temperature (Tg) and crystallization temperature (Tx), whereby ΔTx (Tg-Tx) was determined to be 36°C. Then, the powder was kept at a temperature lower than the glass transition temperature of 400° C. to perform heat treatment in the atmosphere for 0.5 hours, thereby forming oxides on the surface of the powder.

[0150] In addition, a silicone resin as a binder was added to the oxide-formed powders in amounts of 5%, 2.5%, 1%, and 0.5%, respectively, to obtain respective powders. Using a pressed part with a groove with an outer diameter of 27mm and an inner d...

example 134

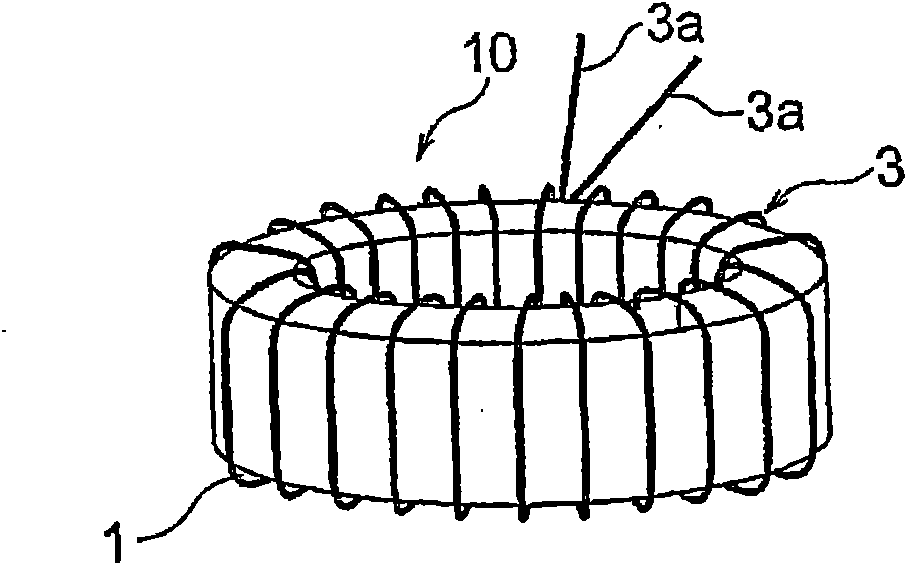

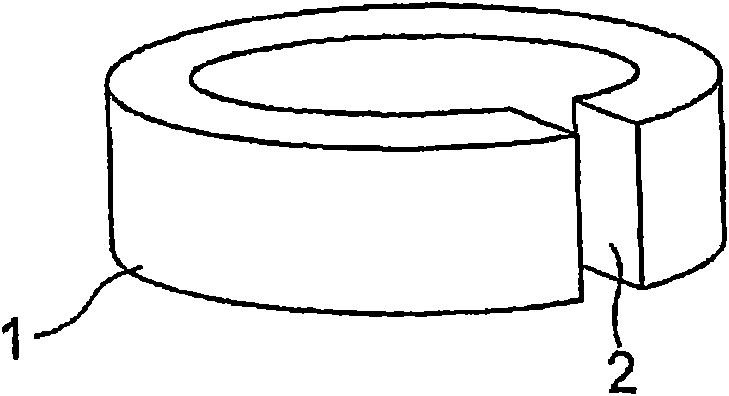

[0155] In Example 134, an inductive part corresponding to the 10th sample in Example 133 was prepared using the same alloy powder and the same manufacturing process and subjected to a heat treatment at 450°C for 0.5 hours in a nitrogen atmosphere High-frequency magnetic cores to manufacture inductive components. In addition, for comparison, an inductance component was produced using Al-Si-Fe powder as a magnetic core material, 6.5% silicon steel, and Fe-based amorphous material. Each inductive component is as figure 2 shown, but can also be as Figure 4 Inductive components shown with notches in part of the magnetic circuit. For each of these inductive components, for the magnetic flux density (at 1.6×10 4 A / m), DC resistivity (Ω·cm), permeability for normalization of inductance value, and core loss (20kHz 0.1T) were measured. The results are shown in Table 15.

[0156] It can be understood from Table 15 that the magnetic flux density of the inductance part of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com