Heating processing technology for wear-resistant cutting board

A knife plate and process technology, applied in the field of heat treatment process of wear-resistant knife plate, can solve the problems of low production efficiency, energy waste, etc., and achieve the effects of improving production efficiency, saving energy consumption, and reasonable heat treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

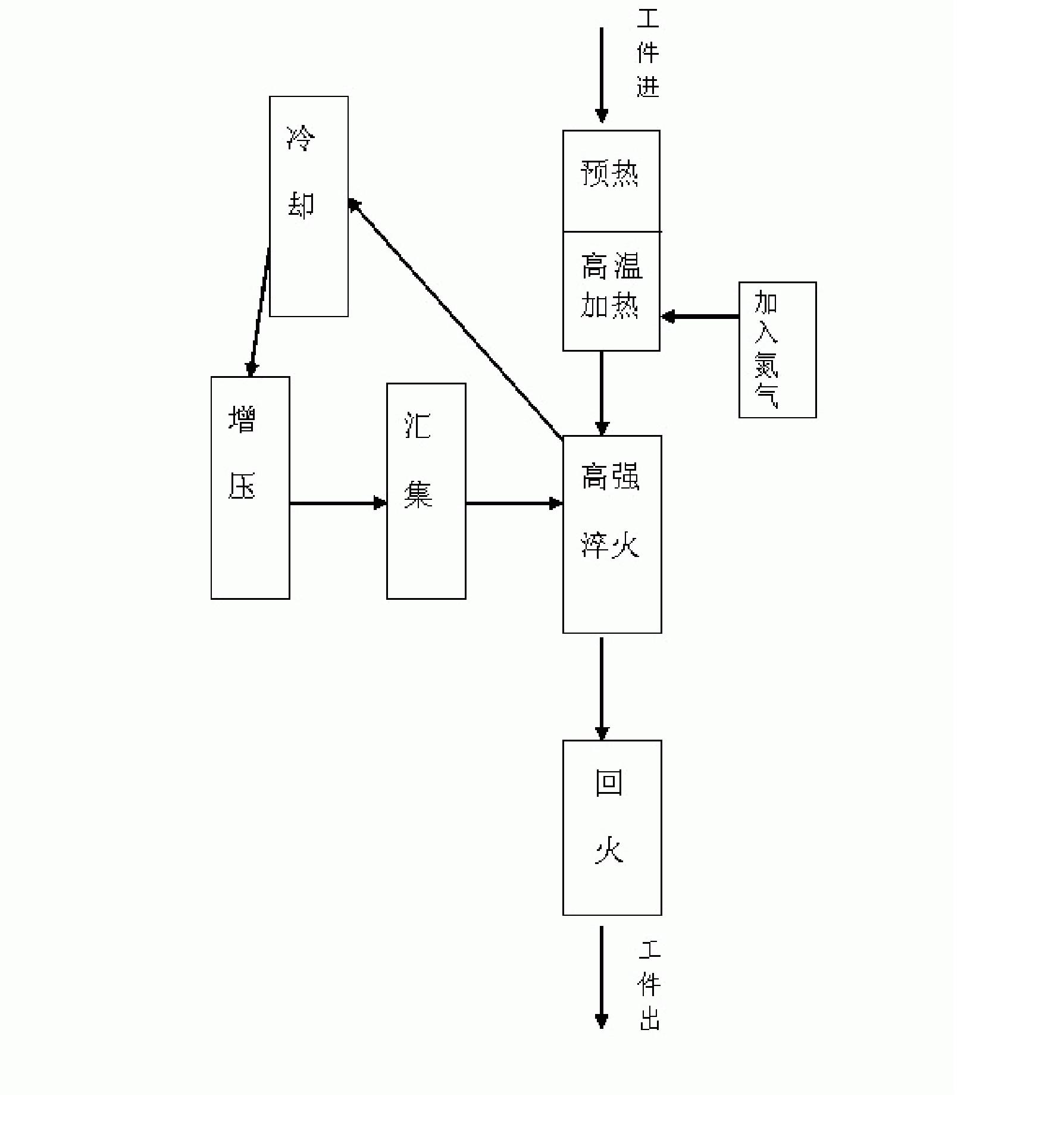

[0034] A heat treatment process for a wear-resistant knife plate with a thickness of 40mm. The process is to preheat and heat the formed wear-resistant knife plate workpiece, and then undergo high-strength quenching and tempering in sequence. The main steps are as follows:

[0035] A. Preheating: Transport the formed wear-resistant knife plate workpiece to the preheating zone of the heating system for preheating. The preheating temperature is 550°C, and the preheating time is 1.125min / mm, which is 45 minutes ;

[0036] B. High-temperature heating: Send the preheated wear-resistant knife plate workpiece to the high-temperature zone of the heating system for high-temperature heating, the temperature is 890°C, and keep warm for 1.125min / mm, which is 45 minutes. The nitrogen machine is added with protective gas nitrogen;

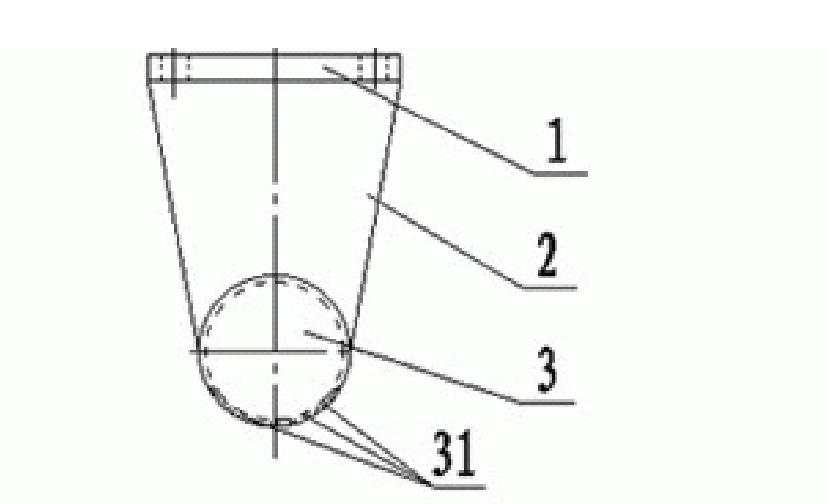

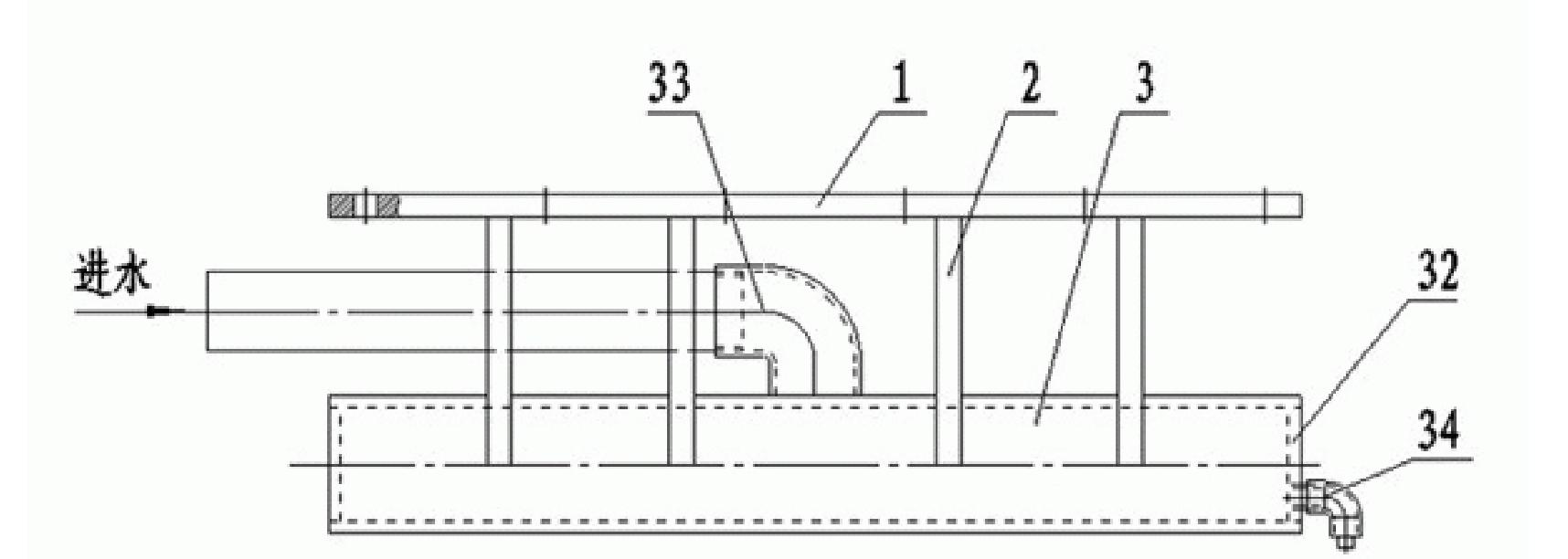

[0037] C. High-strength quenching: The heated wear-resistant knife plate workpiece is transported to a press quenching machine with a high-strength quenching n...

Embodiment 2

[0046] A heat treatment process for a wear-resistant knife plate with a thickness of 35mm. The main steps of the process and the high-pressure cooling water and high-strength quenching nozzles used are the same as those in Example 1, except that the process parameters in the main steps are different. The main steps of sharpening the board are as follows:

[0047] A. Preheating: Transport the formed wear-resistant knife plate workpiece to the preheating zone of the heating system for preheating. The preheating temperature is 500°C, and the preheating time is 1.086min / mm, which is 38 minutes ;

[0048] B. High-temperature heating: Send the preheated wear-resistant knife plate workpiece to the high-temperature zone of the heating system for high-temperature heating. Nitrogen machine added protective gas nitrogen;

[0049] C. High-strength quenching: The heated wear-resistant knife plate workpiece is transported to the press quenching machine of the quenching system, and high-st...

Embodiment 3

[0052] A heat treatment process for a wear-resistant knife plate with a thickness of 30mm. The main steps of the process and the high-pressure cooling water and high-strength quenching nozzles used are the same as those in Example 1, except that the process parameters in the main steps are different. The main steps of sharpening the board are as follows:

[0053] A. Preheating: Transport the formed wear-resistant knife plate workpiece to the preheating zone of the heating system for preheating. The preheating temperature is 450°C, and the preheating time is 1min / mm, which is 30 minutes;

[0054] B. High-temperature heating: send the preheated wear-resistant knife plate workpiece to the high-temperature zone of the heating system for high-temperature heating, the temperature is 870°C, and keep it warm for 1min / mm, that is, 30 minutes, and at the same time pass nitrogen Add protective gas such as nitrogen to the machine;

[0055] C. High-strength quenching: The heated wear-resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com