Polyether-ether-ketone polymer and preparation method thereof

A polyether ether ketone and polymer technology, applied in the field of polyetherether ketone polymers and their preparation, can solve problems such as difficult processing, achieve the effect of increasing cost and improving polymer properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

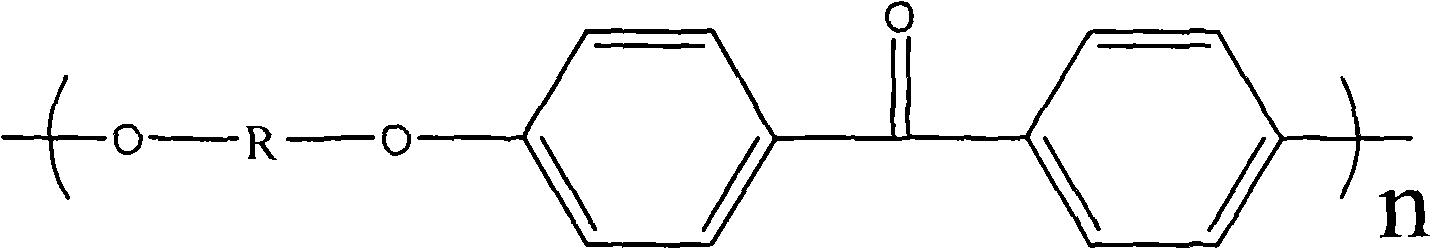

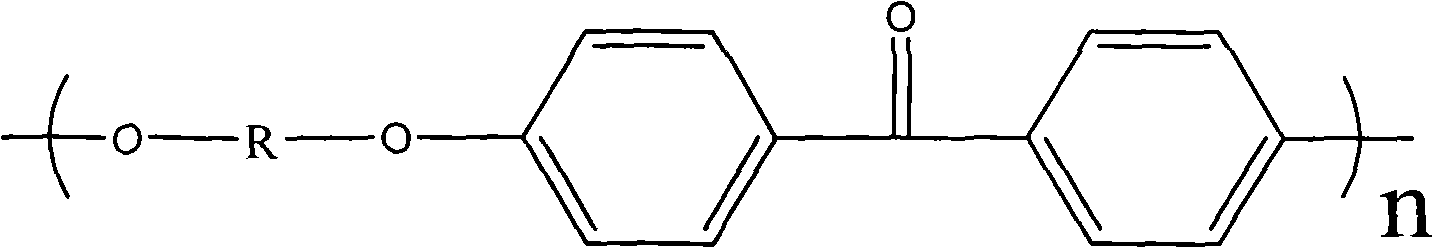

[0026] Add 0.0115mol [3,6]-methylene-4cyclohexene-4-hydroquinone and 0.0145mol anhydrous potassium carbonate to a three-necked flask equipped with a magnetic stirrer, an oil-water separator and a thermometer, and add 40mLN , N-dimethylacetamide. After stirring for 0.5 hours at room temperature, add 0.0115mol 4,4'-difluorobenzophenone, add 40mL N,N-dimethylacetamide, then add 40mL water-carrying agent toluene, heat to 130°C, and keep the temperature for 4 hours . Then the temperature was raised to 166° C., and the temperature was maintained for 18 hours to obtain a random polymer. All the above reactions were carried out under nitrogen protection. R is structural formula 1.

[0027] Refining: Pour the random polymer into water, soak for 12 hours, filter, then pour the solid into methanol, soak for 12 hours, and filter. The above process was repeated 5-6 times, and dried in an oven at 110° C. for 12 hours to obtain a refined polymer. (the refining means of the following exa...

Embodiment 2

[0033] Add 0.0115mol [3,6]-methylene-4cyclohexene-4-hydroquinone and 0.0145mol anhydrous potassium carbonate to a three-necked flask equipped with a magnetic stirrer, an oil-water separator and a thermometer, and add 40mLN , N-dimethylacetamide. After stirring at room temperature for 0.5 hours, add 0.0115mol 4,4'-difluorobenzophenone, add 40mL N,N-dimethylacetamide, and then add 40mL water-carrying agent toluene. Heat to 130°C and maintain temperature for 4 hours. Then the temperature was raised to 165° C., and the temperature was maintained for 20 hours to obtain a random polymer. All the above reactions were carried out under nitrogen protection. After further refining steps, refined polymers are obtained. R is structural formula 1.

[0034] Characterization data: Tg (°C): 170, Tm (°C): 351, tensile strength (MPa): 88, elongation at break (%): 95

[0035] IR, cm -1 : 3068, 3002, 2938, 2868, 1651, 1559, 1474, 1230, 1160, 928, 854, 756, 734.

[0036] 1 H NMR, δ: 2.1-2....

Embodiment 3

[0039] Add 0.0115mol [3,6]-methylene-4cyclohexene-4-hydroquinone and 0.0145mol anhydrous potassium carbonate to a three-necked flask equipped with a magnetic stirrer, an oil-water separator and a thermometer, and add 40mLN , N-dimethylacetamide. After stirring at room temperature for 0.5 hours, add 0.0115mol 4,4'-difluorobenzophenone, add 40mL N,N-dimethylacetamide, and then add 40mL water-carrying agent toluene. Heat to 130°C and maintain temperature for 4 hours. Then the temperature was raised to 166° C., and the temperature was maintained for 22 hours to obtain a random polymer. All the above reactions were carried out under nitrogen protection. After further refining steps, refined polymers are obtained. R is structural formula 1.

[0040] Characterization data: Tg (°C): 170, Tm (°C): 350, tensile strength (MPa): 89, elongation at break (%): 95

[0041] IR, cm -1 : 3068, 3002, 2938, 2868, 1651, 1559, 1474, 1230, 1160, 928, 854, 756, 734.

[0042] 1 H NMR, δ: 2.1-2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com