Method for preparing color liquid SBS modified emulsion resin

A liquid and modified technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of poor product performance, high production cost, complicated process, etc., and achieve superior road performance and production The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

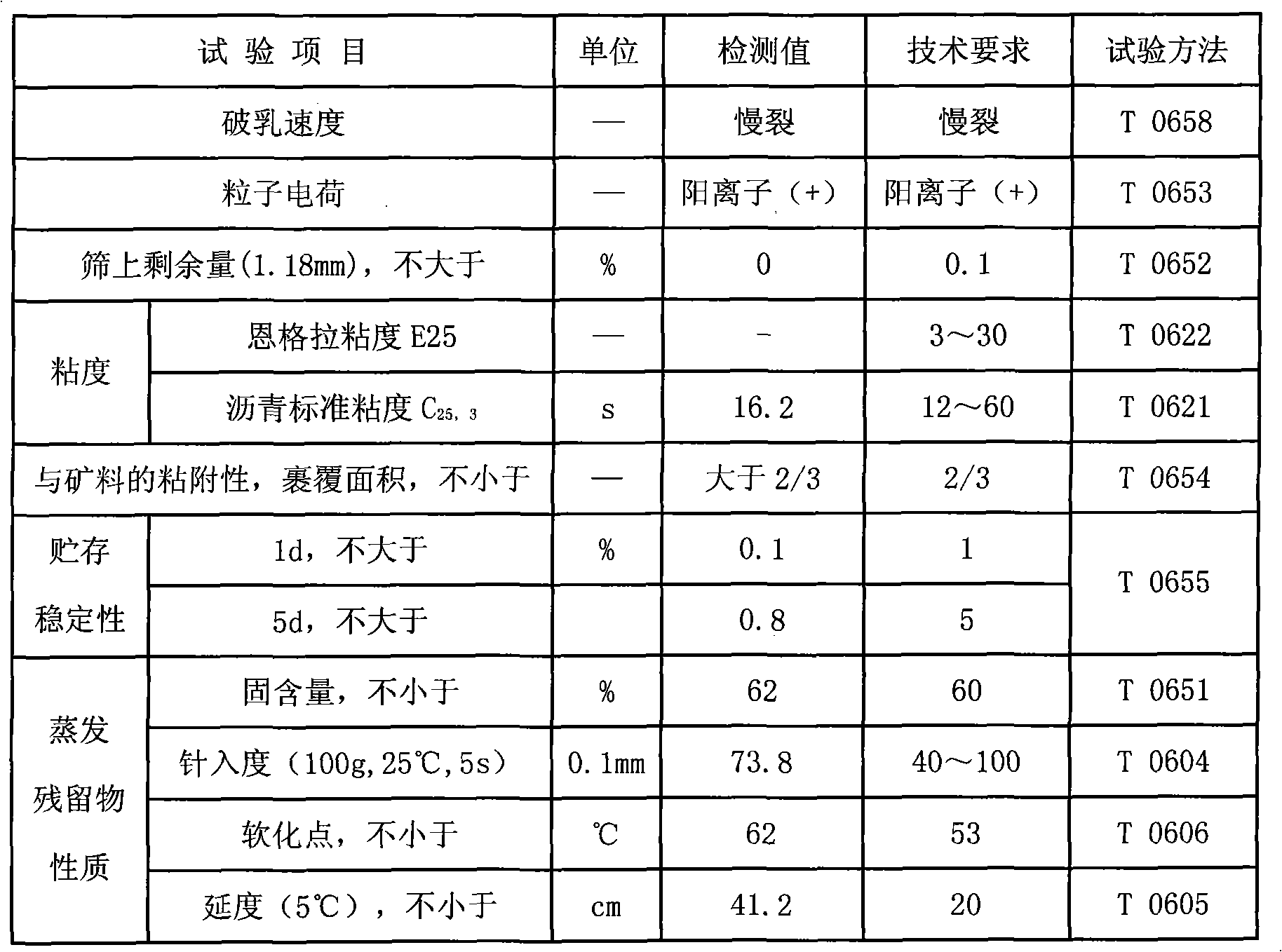

Examples

Embodiment 1

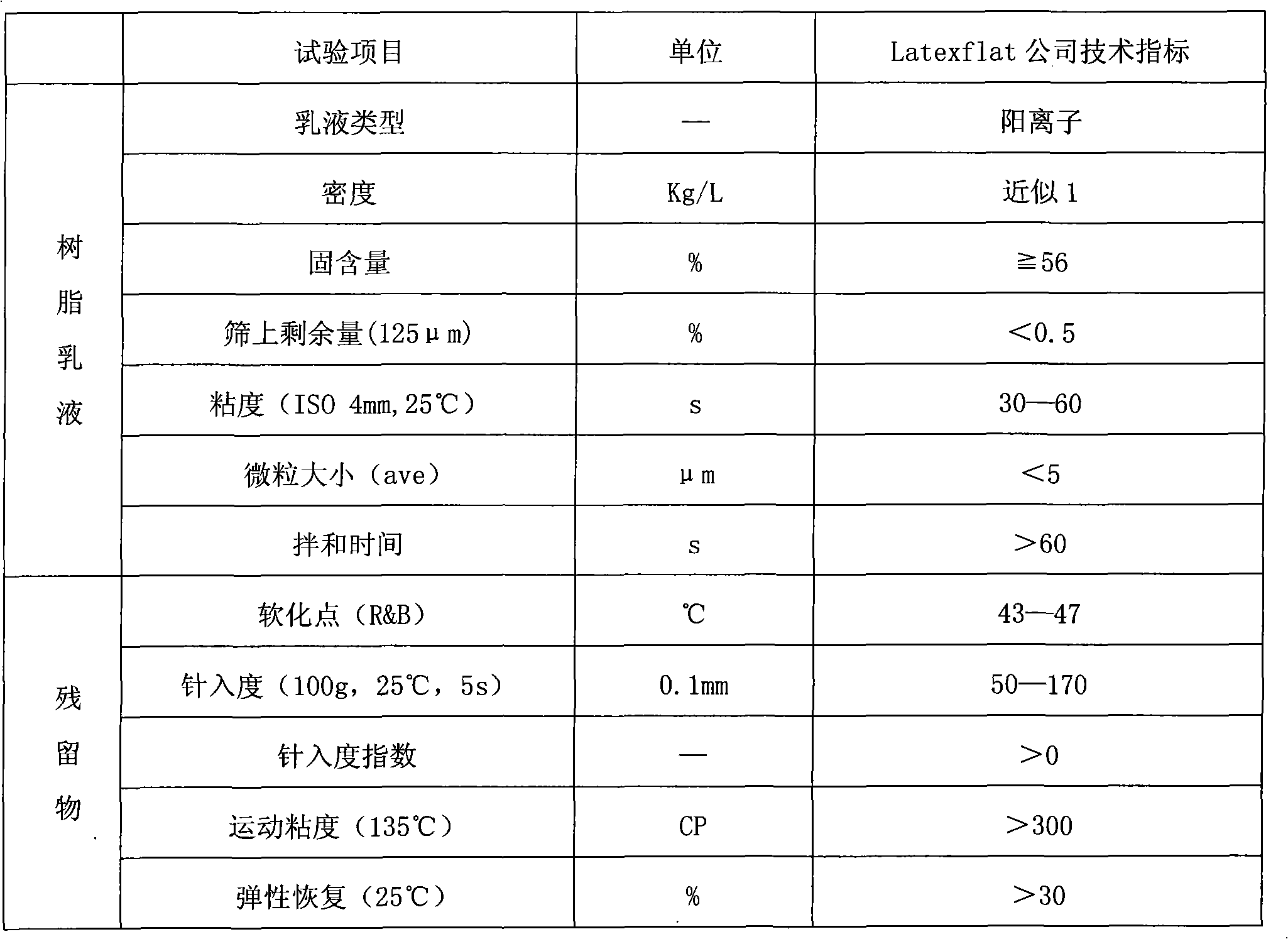

[0030] (1) Raw material quality

[0031] Bright color resin: 100 kg

[0032] Liquid SBS modifier: 4 kg

[0033] Inorganic pigment: 1 kg of 307 molybdenum chrome red pigment or 1 kg of SGC-M chrome green pigment

[0034] Pigment dispersant: 0.003 kg polycarboxylate sodium salt or 0.003 kg polyacrylate ammonium salt

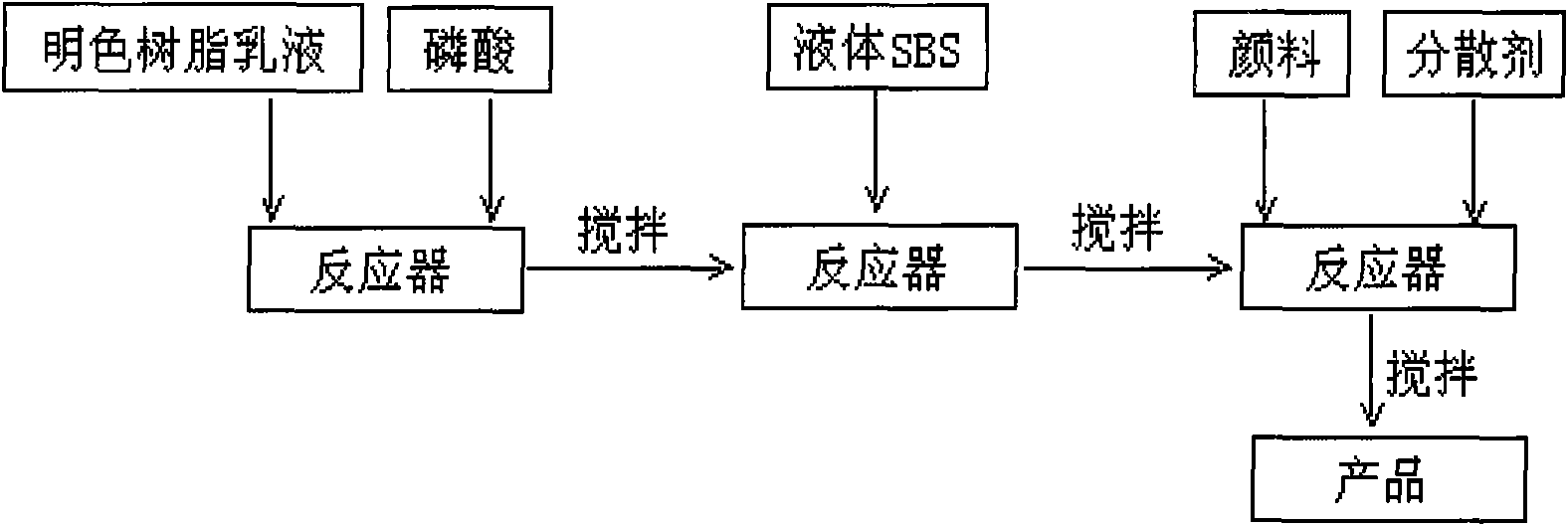

[0035] (2) Preparation process (such as figure 1 shown)

[0036] 1. Add the bright-colored resin emulsion into the reactor, keep the temperature of the reactor at 20°C to 30°C, and start stirring;

[0037] 2. Add phosphoric acid to the reaction kettle, adjust the pH of the system to 2.5-4.5, and stir to make the system evenly mixed;

[0038] 3. Add liquid SBS modifier to the reaction kettle, and continue to stir until the system is evenly mixed;

[0039] 4. Add inorganic pigment 307 molybdenum chrome red pigment or SGC-M chrome green pigment to the system, and at the same time add pigment dispersant polycarboxylate sodium salt or polyacrylic acid ammonium sal...

Embodiment 2

[0041] (1) Raw material quality

[0042] Bright color resin: 100 kg

[0043] Liquid SBS modifier: 7 kg

[0044] Inorganic pigment: 3.5 kg of 307 molybdenum chrome red pigment or 3.5 kg of SGC-M chrome green pigment

[0045] Pigment dispersant: 0.105 kg polycarboxylate sodium salt or 0.105 kg polyacrylic acid ammonium salt

[0046] (2) The preparation process is the same as in Example 1.

Embodiment 3

[0048] (1) Raw material quality

[0049] Bright color resin: 100 kg

[0050] Liquid SBS modifier: 5.5 kg

[0051] Inorganic pigment: 2.5 kg of 307 molybdenum chrome red pigment or 2.5 kg of SGC-M chrome green pigment

[0052] Pigment dispersant: 0.03 kg polycarboxylate sodium salt or 0.03 kg polyacrylate ammonium salt

[0053] (2) The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com