Karaya gum complex polysaccharide microsphere used as bioactive molecular vector and preparation method thereof

A technology of biologically active molecules, karaya gum, applied in the direction of being fixed on/in an organic carrier, can solve the problem of not involving the preparation method and application of microspheres, poor mechanical properties and poor stability of biological polysaccharide microspheres and other problems, to achieve the effect of simplifying the production operation process, wide application range and abundant resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

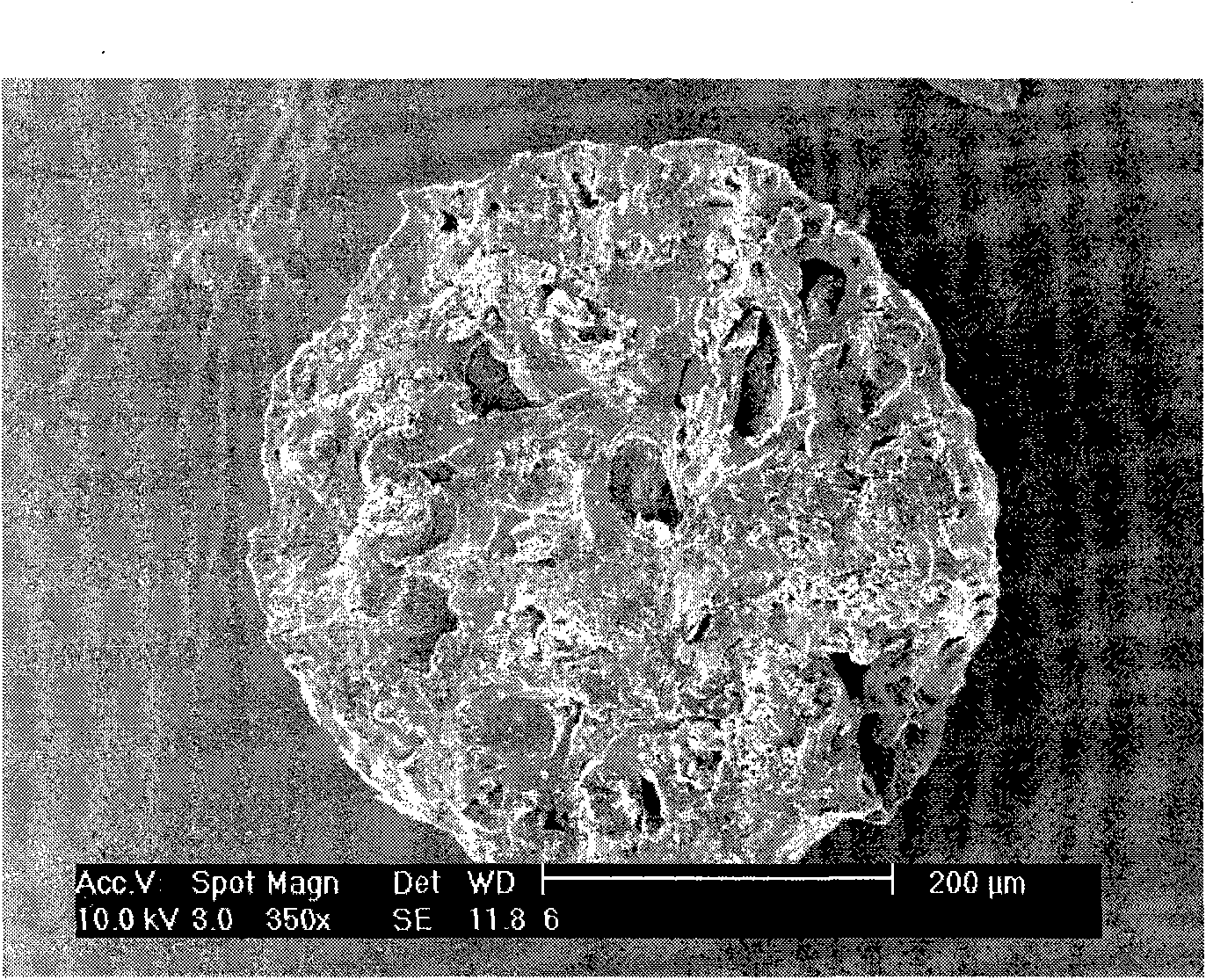

Image

Examples

Embodiment 1

[0027] Step 1. get a certain amount of karaya gum and join in the sodium hydroxide aqueous solution that massfraction is 40%, the sodium hydroxide aqueous solution and karaya gum ratio are volume (ml): mass (g)=10: 1, add simultaneously Sodium tetraborate, the mass ratio of karaya gum to sodium tetraborate is 5:1, keep the temperature in a water bath at 60°C for 22 hours, then neutralize the excess alkali with glacial acetic acid with a concentration of 90%, and use a dialysis bag with a molecular weight cut-off of 8000-10000 Dialysis in flowing distilled water at room temperature for 48 hours to remove excess salt, vacuum drying at 50°C and 0.08 MPa for 68 hours to obtain deacetylated karaya gum dry powder, with a degree of deacetylation of 86%;

[0028] Step 2. the karaya gum of deacetylation is mixed with chitosan, and mass ratio is 1: 1, joins in distilled water under 20 ℃, 1000rpm / min rotating speed (containing the glacial acetic acid that volume ratio is 1.0% in the aqueo...

Embodiment 2

[0033]Step 1. get a certain amount of karaya gum and join in the sodium hydroxide aqueous solution that massfraction is 40%, the sodium hydroxide aqueous solution and karaya gum ratio are volume (ml): mass (g)=11: 1, add simultaneously Sodium tetraborate, the mass ratio of karaya gum to sodium tetraborate is 4:1, keep the temperature in a water bath at 60°C for 24 hours, then neutralize the excess alkali with 90% glacial acetic acid, and use a dialysis bag with a molecular weight cut-off of 8000-10000 Dialysis in flowing distilled water at room temperature for 48 hours to remove excess salt, vacuum drying at 50°C and 0.08MPa for 73 hours to obtain deacetylated karaya gum dry powder, with a degree of deacetylation of 85%;

[0034] Step 2. the karaya gum of deacetylation is mixed with chitosan, and mass ratio is 1.2: 1, joins in distilled water under 22 ℃, 1000rpm / min rotating speed (containing the glacial acetic acid that volume ratio is 1.3% in the aqueous solution), Obtaining...

Embodiment 3

[0039] Step 1. get a certain amount of karaya gum and join in the sodium hydroxide aqueous solution that mass fraction is 40%, the sodium hydroxide aqueous solution and karaya gum ratio are volume (ml): mass (g)=12: 1, add simultaneously Sodium tetraborate, the mass ratio of karaya gum to sodium tetraborate is 3:1, keep the temperature in a water bath at 60°C for 26 hours, then neutralize the excess alkali with 90% glacial acetic acid, and use a dialysis bag with a molecular weight cut-off of 8000-10000 Dialysis in flowing distilled water at room temperature for 48 hours to remove excess salt, vacuum drying at 50°C and 0.08MPa for 76 hours to obtain deacetylated karaya gum dry powder, with a degree of deacetylation of 82%;

[0040] Step 2. the karaya gum of deacetylation is mixed with chitosan, and mass ratio is 1.3: 1.1, joins in distilled water under 25 ℃, 1000rpm / min rotating speed (containing the glacial acetic acid that volume ratio is 1.6% in the aqueous solution), Obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com