Method for preparing solar energy level silicon crystals containing doped element

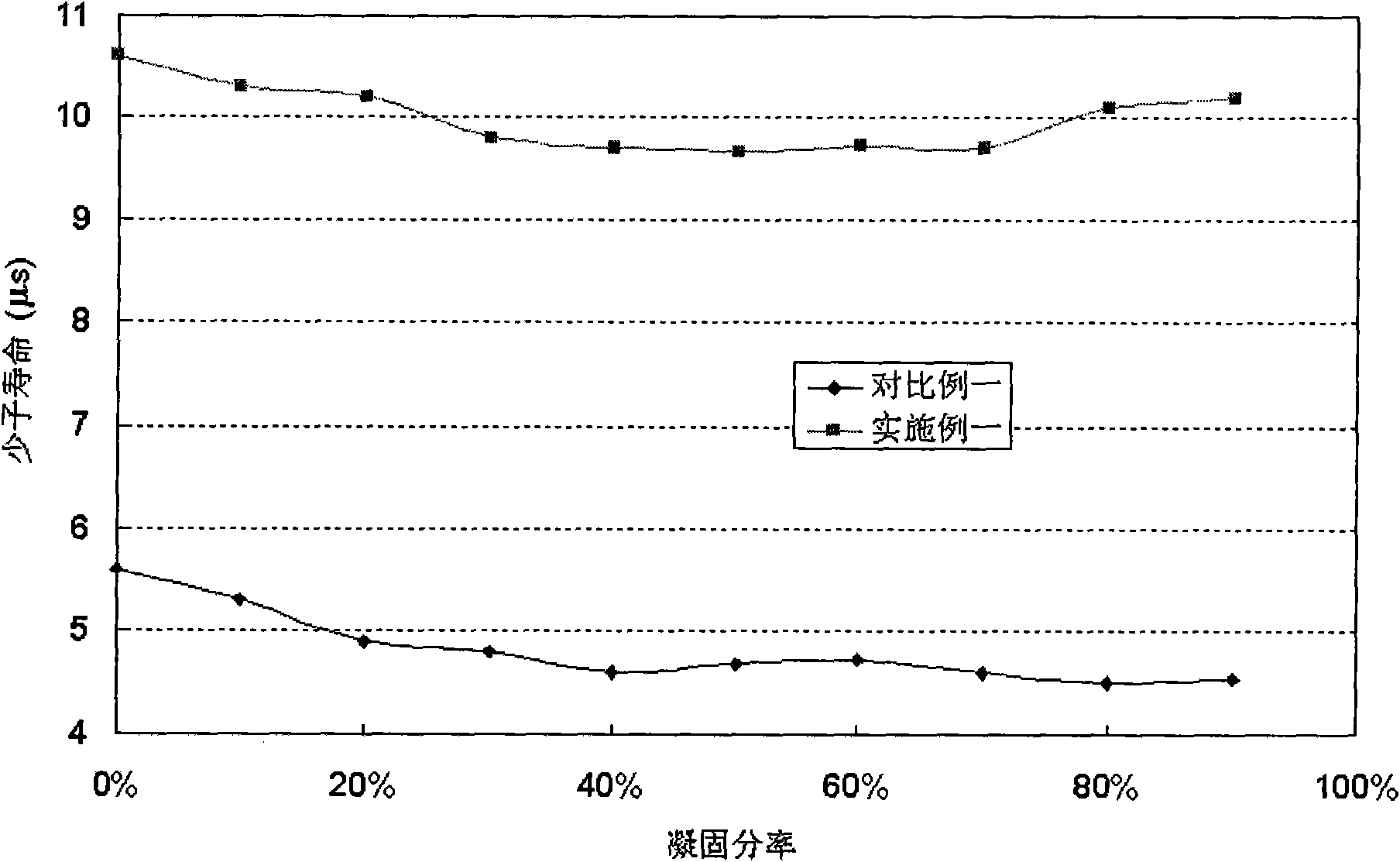

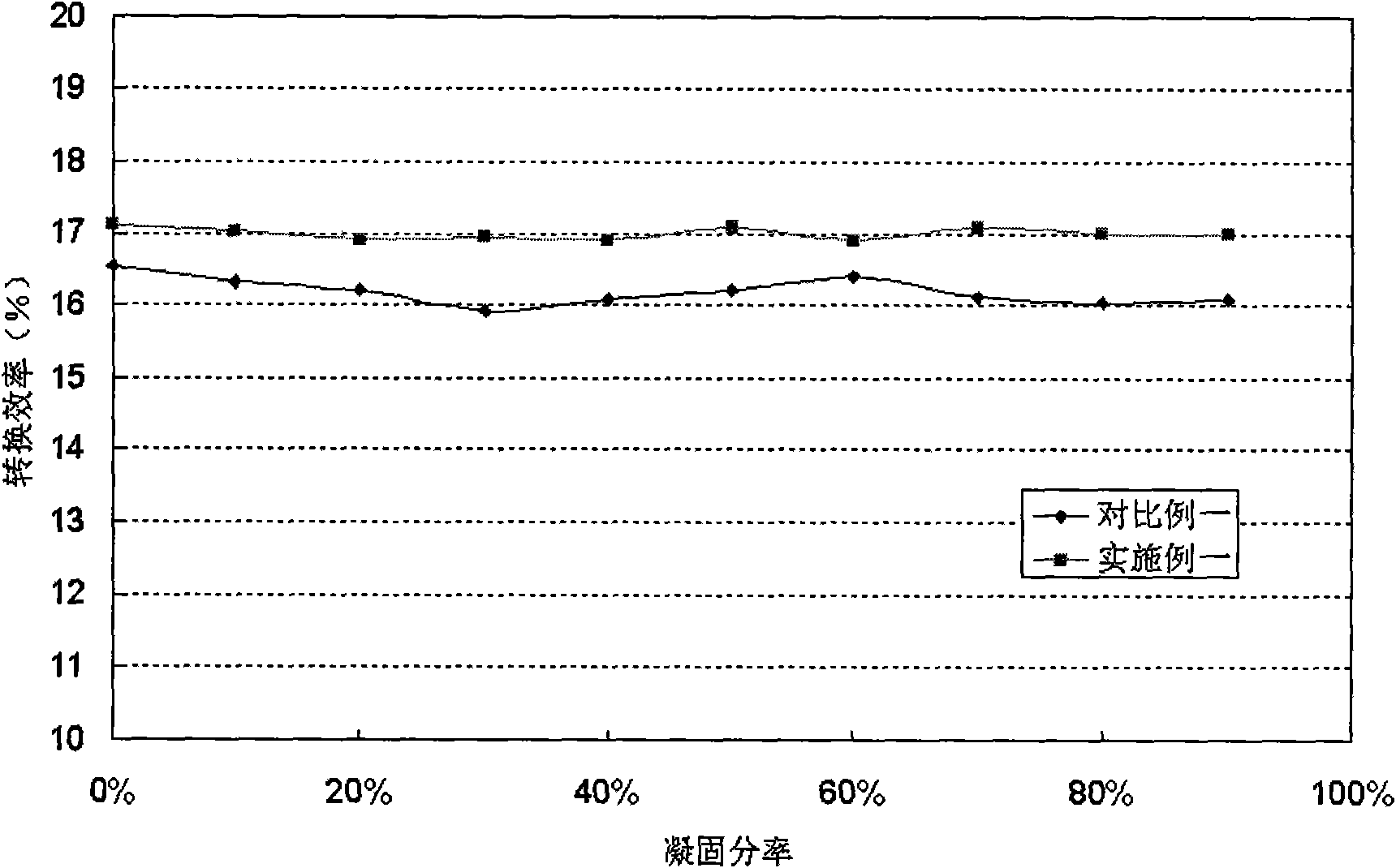

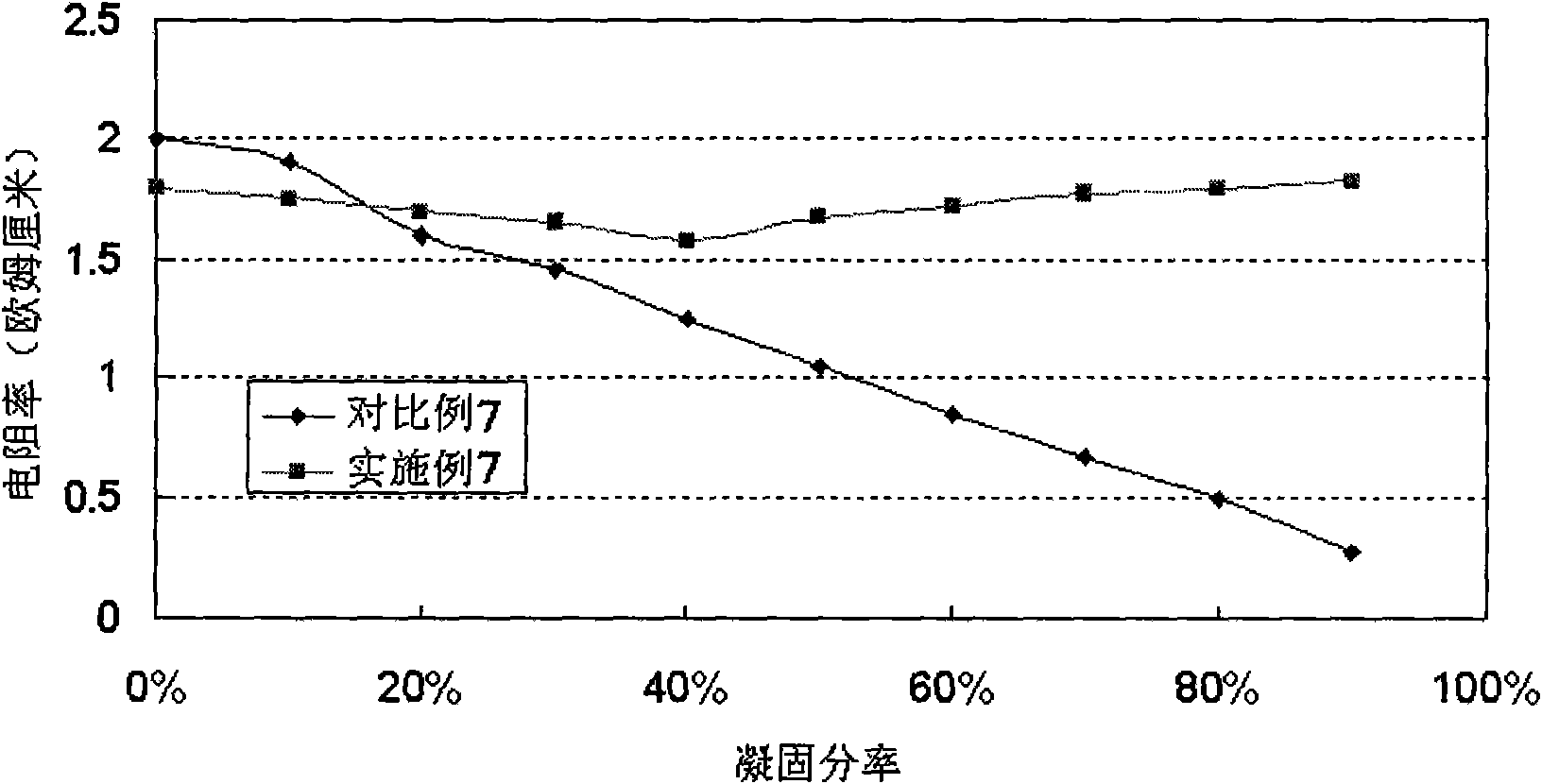

A doping element, solar-grade technology, applied in the silicon crystal field of high-conversion-efficiency solar cells, can solve problems such as uneven resistivity distribution and small segregation coefficient of gallium-doped silicon ingots, so as to improve photoelectric conversion efficiency and minority-carrier lifetime The effect of improving and improving the life expectancy of the minority

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The Czochralski method was used to prepare silicon crystals for the manufacture of high conversion efficiency solar cells. 50Kg of raw material is put into the furnace, and its mass percentage composition is composed of 50% primary polysilicon material and 50% boron-containing crucible bottom material. Among them, the primary polysilicon material contains 0.5 mg of boron and 0.1 mg of phosphorus. Boron in the bottom material of the crucible is 5.5 mg, and phosphorus in the bottom material of the crucible is 0.9 mg. 100% Ar gas was introduced to protect the material. After the chemical material is completed, the gas that is passed into is changed to 40% H by volume percentage. 2 Gas, a protective gas composed of 60% Ar gas. Properly adjust the flow rate of the protective gas and the pumping rate of the vacuum pump to control the pressure in the furnace at about 1000Pa, and the flow rate of the protective gas through the surface of the silicon melt is 40slpm / m 2 . Wh...

Embodiment 2

[0056] The directional solidification method (using DSS method polysilicon ingot furnace) is used to prepare silicon crystals for manufacturing high conversion efficiency solar cells. In the polysilicon ingot furnace, the silicon melt (doped with phosphorus with a mass concentration of 0.1ppmw) is stored in a quartz crucible, and the protective gas composed of 50% argon and 50% hydrogen by volume is passed through the conductor. The gas pipe is introduced from the top of the polysilicon ingot furnace. The flow rate of shielding gas through the surface of silicon melt is 60slpm / m 2 . By changing the heating power of the heater to adjust the temperature field distribution in the furnace, the silicon crystal grows upward from the bottom of the quartz crucible to prepare the silicon crystal. When the silicon is completely crystallized, continue to pass the protective gas until the temperature of the silicon crystal is lower than 500°C.

Embodiment 3

[0058] Using the process of Example 1 to prepare boron-doped silicon crystals, the difference is that the protective gas is 100% by volume of SiH 4 gas composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com