Non-oriented electric steel semi-organic phosphate insulating paint with good corrosion resistance

A technology of oriented electrical steel and organic phosphate, which is applied in the direction of anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of corrosion resistance to be improved, and achieve improved coating appearance, good insulation, and improved corrosion resistance. erosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

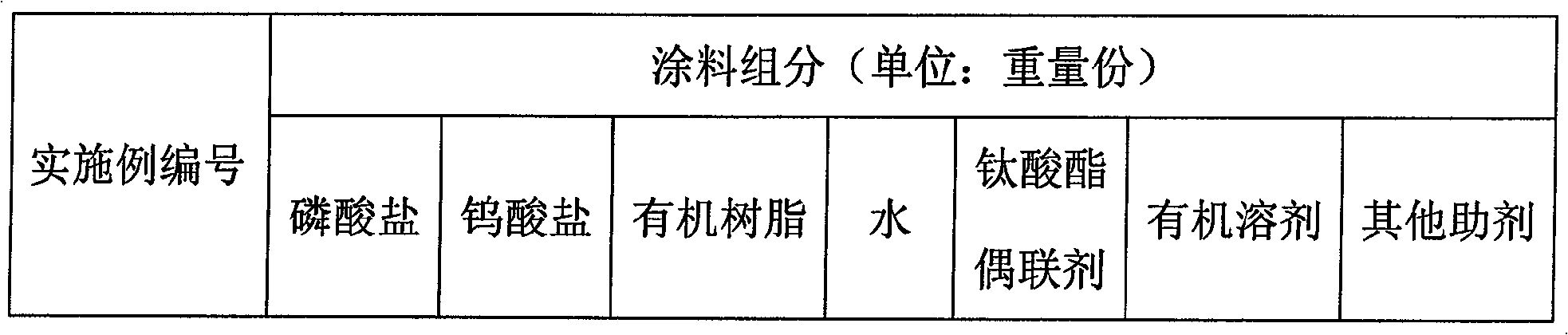

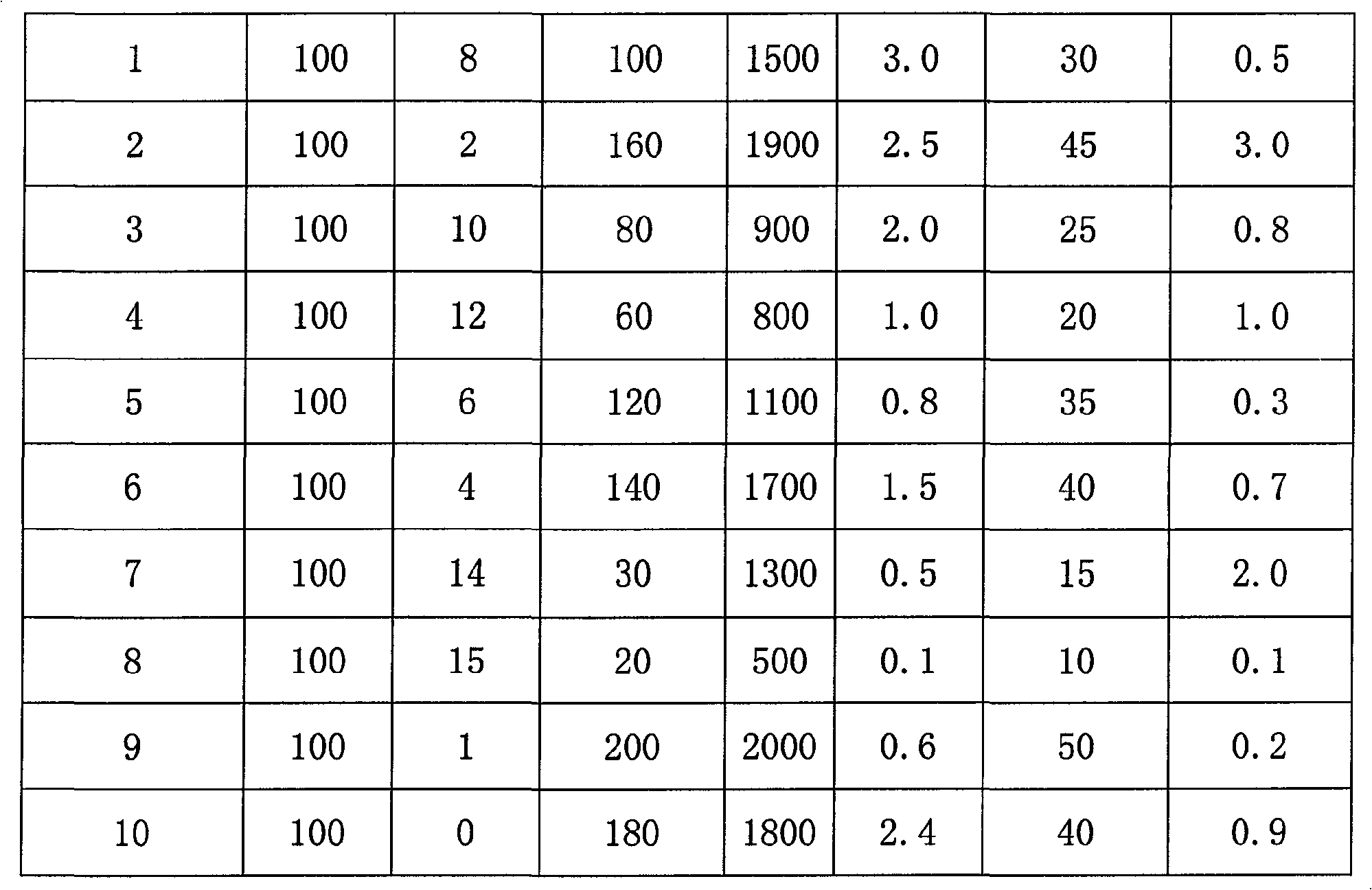

Embodiment 1-10

[0023] In above-mentioned embodiment 1-10:

Embodiment 1

[0024] Phosphate described in embodiment 1 is the mixture of aluminum dihydrogen phosphate, magnesium dihydrogen phosphate; Tungstate is sodium tungstate; Organic resin is styrene-acrylic acid copolymer resin, and organic solvent is ethylene glycol; Described other Additives are wetting agents and defoamers.

Embodiment 2

[0025] Phosphate described in embodiment 2 is the mixture of aluminum dihydrogen phosphate, nickel dihydrogen phosphate; Tungstate is potassium tungstate; Organic resin is acrylic resin, polyurethane resin, and organic solvent is ethylene glycol; Described other auxiliary The agent is a leveling agent and a defoamer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com