Aluminum-doped zinc oxide film coating and nano-rod array material as well as preparation method thereof

A technology of aluminum-doped zinc oxide and nanorod arrays, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., to achieve the effects of improved utilization, good electrical conductivity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

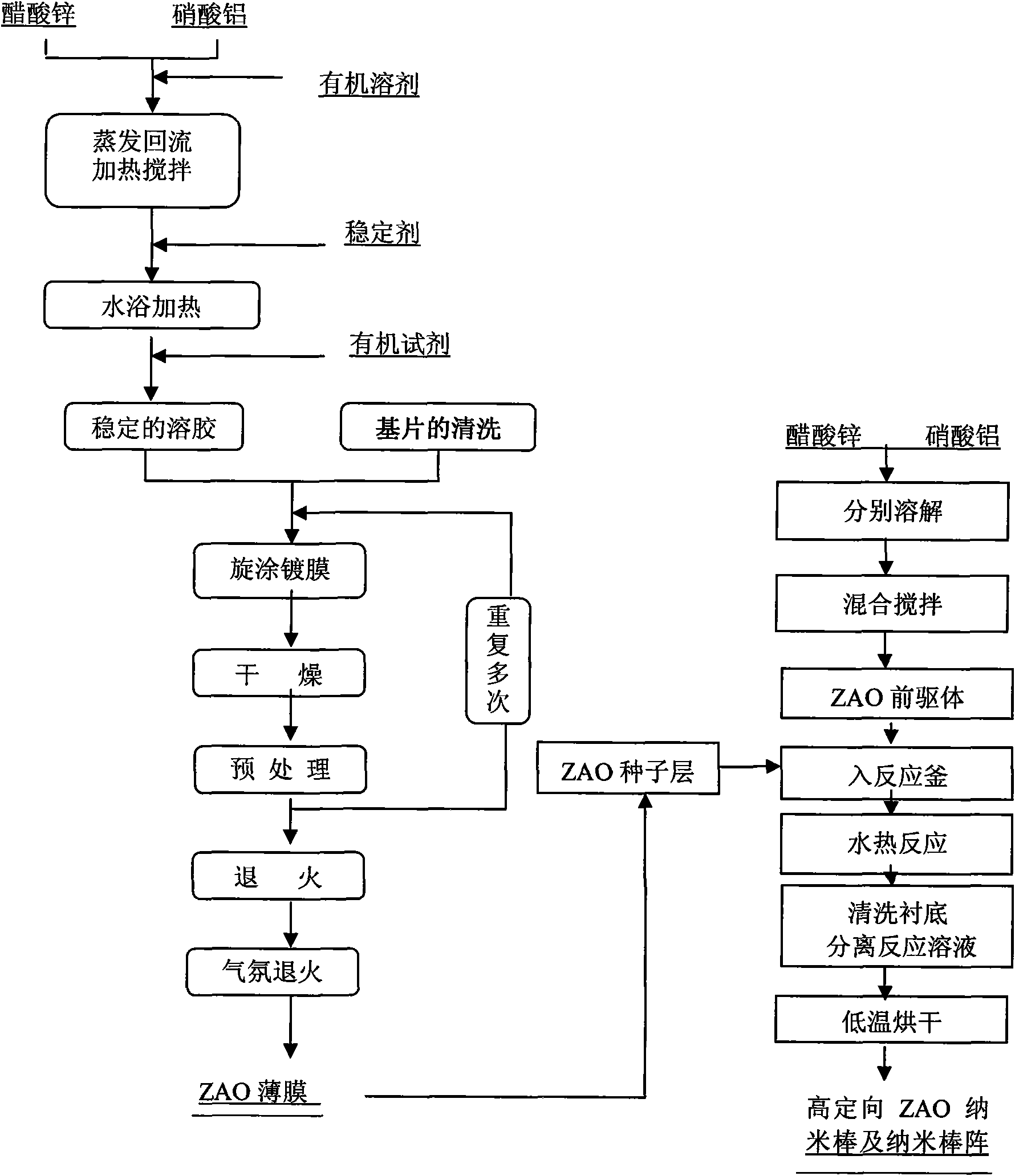

Method used

Image

Examples

Embodiment 1

[0028]Embodiment 1: take by weighing zinc acetate dihydrate 65.853g, aluminum nitrate nonahydrate 5.418g, be dissolved in it completely in the organic solvent and be made into 250 milliliters of solutions, organic solvent can select ethylene glycol methyl ether for use, evaporate to reflux, heat and stir, Add 3.5 milliliters of stabilizer ethanolamine to the solution after reflux, heat and stir in a water bath at 60°C for 1 hour, then add an organic reagent absolute ethanol to set the volume to 500 milliliters, and obtain a transparent homogeneous sol with a concentration of 0.6mol / L. The concentration [Al / Zn] is 2.0%; use glass slides as the substrate, and the substrate should be cleaned. The cleaning method is to wash away the stains on the substrate with washing powder and tap water; soak in 10% NaOH dilute solution to remove oil stains; Soak in potassium dichromate solution; rinse with deionized water; then soak in deionized water, formaldehyde solution, absolute ethanol so...

Embodiment 2

[0029] Embodiment 2: take by weighing zinc acetate dihydrate 43.902g, aluminum nitrate nonahydrate 5.586g, be dissolved in it completely in the organic solvent and be made into 250 milliliters of solutions, organic solvent can select Virahol for use, evaporate and reflux, heat and stir, in reflux Add 4.5 milliliters of stabilizer acetylacetone to the final solution, heat and stir in a water bath at 70°C for 1 hour, then add organic reagent formamide to set the volume to 500 milliliters, and obtain a transparent homogeneous sol with a concentration of 0.4mol / L and a doping concentration of [ Al / Zn] 3.1%; Make substrate with glass slide, substrate should be cleaned up, and cleaning method is with embodiment 1. The spin coating method was used to form the film. First, the glue was dripped at 1000r / min for 20 seconds, and then the glue was homogenized at 3000r / min for 25 seconds. Dry at 100°C for 10 minutes; then pretreat at 300°C for 10 minutes; repeat coating 5-10 times after co...

Embodiment 3

[0030] Embodiment 3: adopt the method for embodiment 1 to prepare aluminum-doped zinc oxide (ZAO) seed layer and make it adhere on the glass sheet that is coated with indium tin oxide (ITO), weigh zinc acetate dihydrate 2.195g and nitric acid nonahydrate respectively 0.1806g of aluminum was dissolved in distilled water respectively, and then the two solutions were mixed, 15g of hexamethylenetetramine was added, and 8 ml of surfactant polyethyleneimine was added, stirred evenly, the volume was set to 500 ml, and stirred evenly to obtain a precursor solution . Wash the ZAO seed layer repeatedly with distilled water, then tilt it into the hydrothermal reaction kettle; pour the precursor solution into the reaction kettle to 60% of the volume, seal the reaction kettle; put the reaction kettle in a vacuum drying oven at 95°C for hydrothermal Reaction, the reaction time is 6h; after the reaction is completed and the reaction kettle is cooled, take out the ITO glass sheet and rinse it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com