Method for producing multi-effect oil-tea-cake meal feed additive

A feed additive and camellia cake meal technology is applied to the processing field of feed or feed additives, which can solve the problems of inconvenient use, high production cost and production efficiency, animal refusal to eat, etc., and achieves high production efficiency, low product use cost and high production efficiency low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

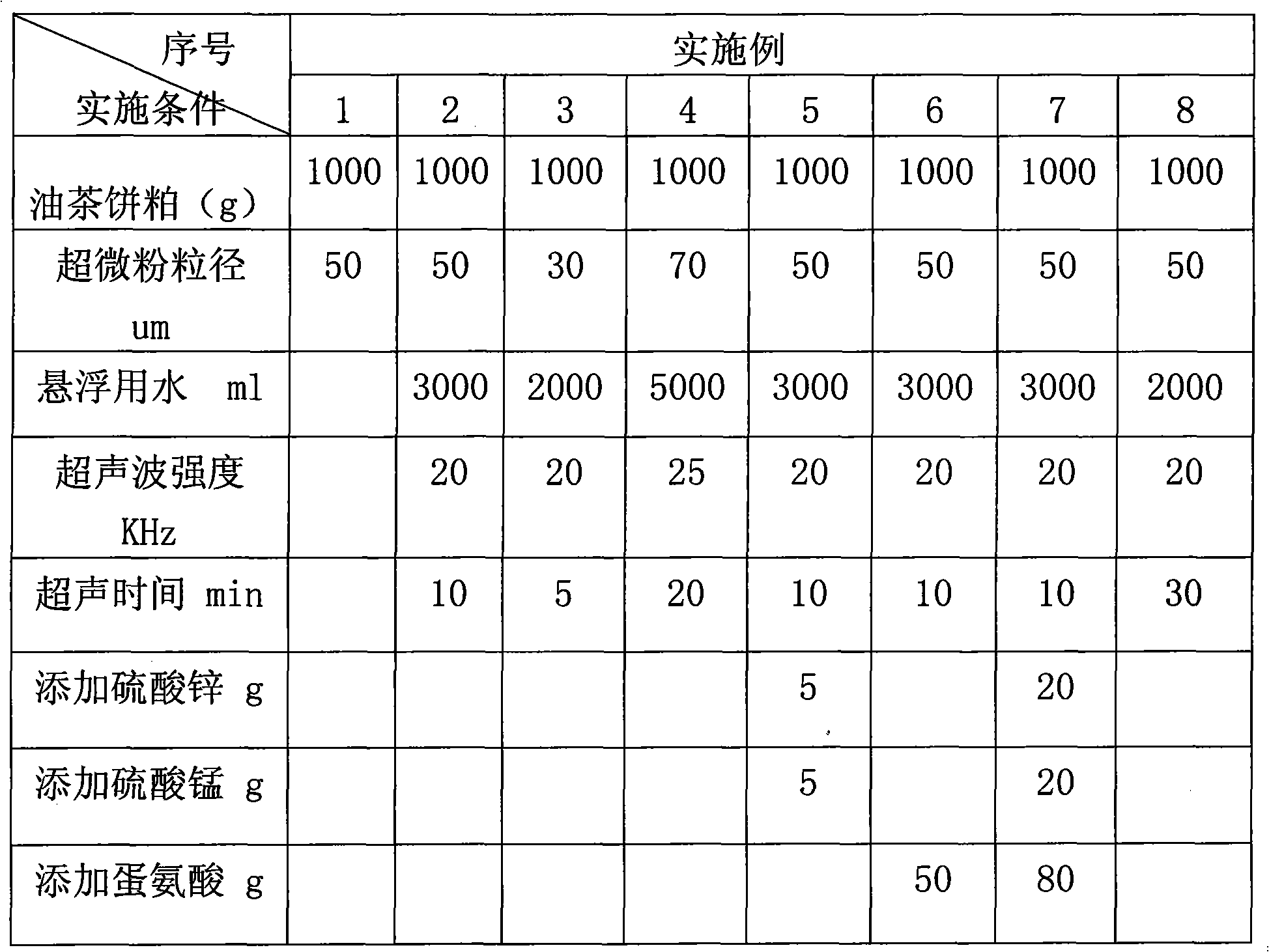

Embodiment 1

[0023] Weigh 1000g of degreased and dried Camellia oleifera cake, first conventionally pulverize it to below 30 mesh, and then superfinely pulverize it into a fine powder with a particle size not exceeding 50um. Observed under a sampling microscope, the cell integrity rate was not more than 40%. The fine powder is vacuum-packed after being granulated to obtain a feed additive or feed material containing various bioactive components such as tea saponin, tea seed polysaccharide, plant flavonoids (polyphenols).

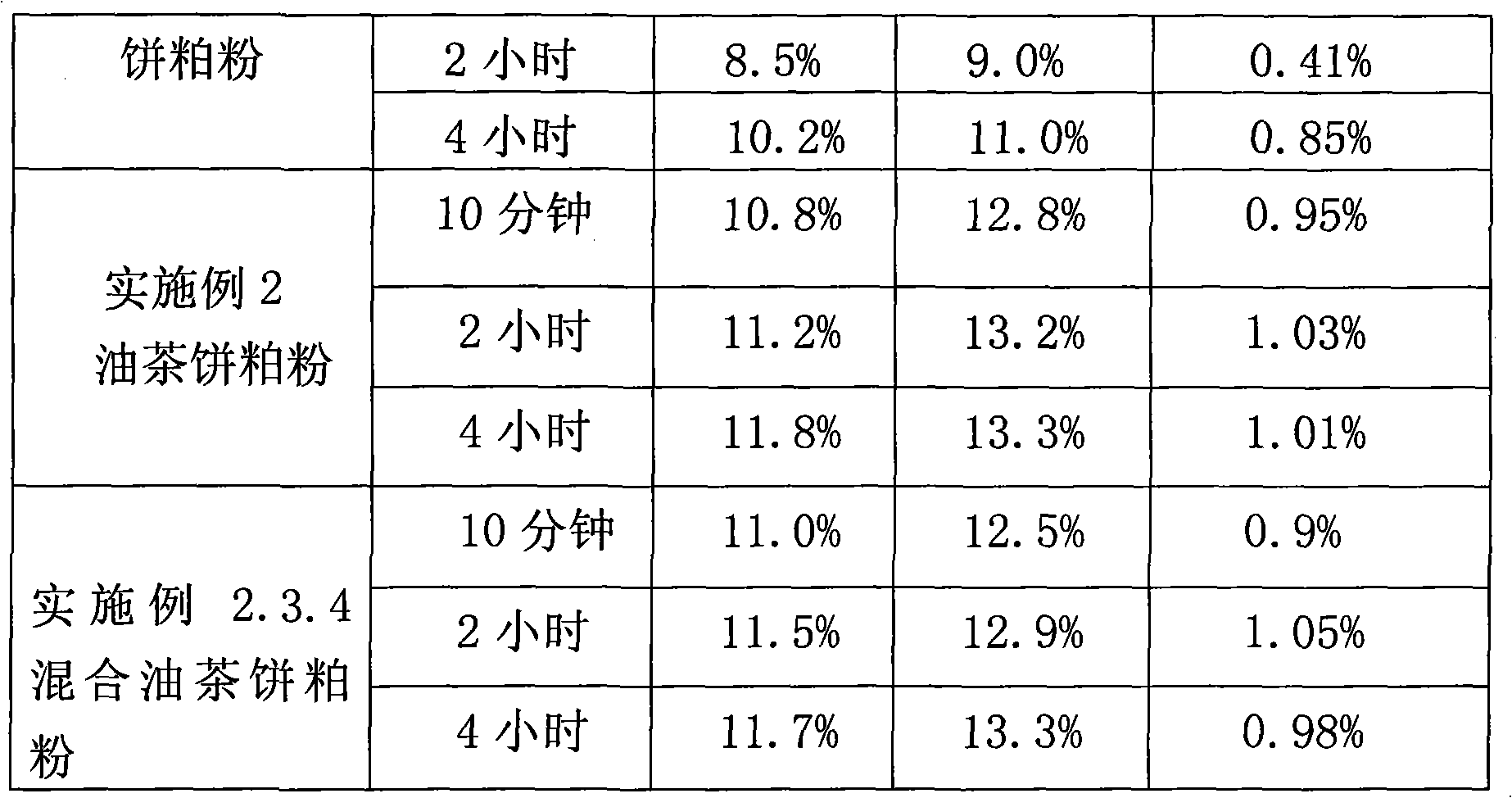

Embodiment 2

[0025] Weigh 1000g of degreased and dried camellia oleifera cake, pulverize it to no more than 30 mesh with a conventional pulverizer, and then ultrafinely pulverize it into a fine powder below 50um, suspend the fine powder evenly in 3000ml of water to form a suspension, and treat it with 20KHz ultrasonic wave for 10 minutes . After the samples were processed and observed under the microscope, almost no intact cells existed. The suspension is granulated by spray drying. Feed additives or feed raw materials containing tea saponin, tea seed polysaccharides, plant flavonoids and other bioactive components are obtained by vacuum packaging. The amount of this additive is generally around 2%.

Embodiment 3

[0027] Weigh 1000g of degreased and dried Camellia oleifera cake, first conventionally pulverize it to below 30 mesh, and then superfinely pulverize it into a fine powder with a particle size of no more than 30um, suspend the fine powder evenly in 2000ml of water to form a suspension, and 20KHz ultrasonic treatment for 5 minute. Observation under the sampling microscope showed that almost no complete cells existed. The suspension is spray-dried and granulated to obtain a feed additive with multiple bioactive components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com