Copper-nickel based multielement high corrosion resisting alloy

A high-corrosion-resistant, copper-nickel-based technology, applied in the field of metal materials, can solve the problems of not fully grasping the specific influence mechanism of added elements, time-consuming and laborious, and not yet discovered, so as to solve the problem of optimizing corrosion-resistant components and overcome arbitrary The effects of toughness, excellent processability and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

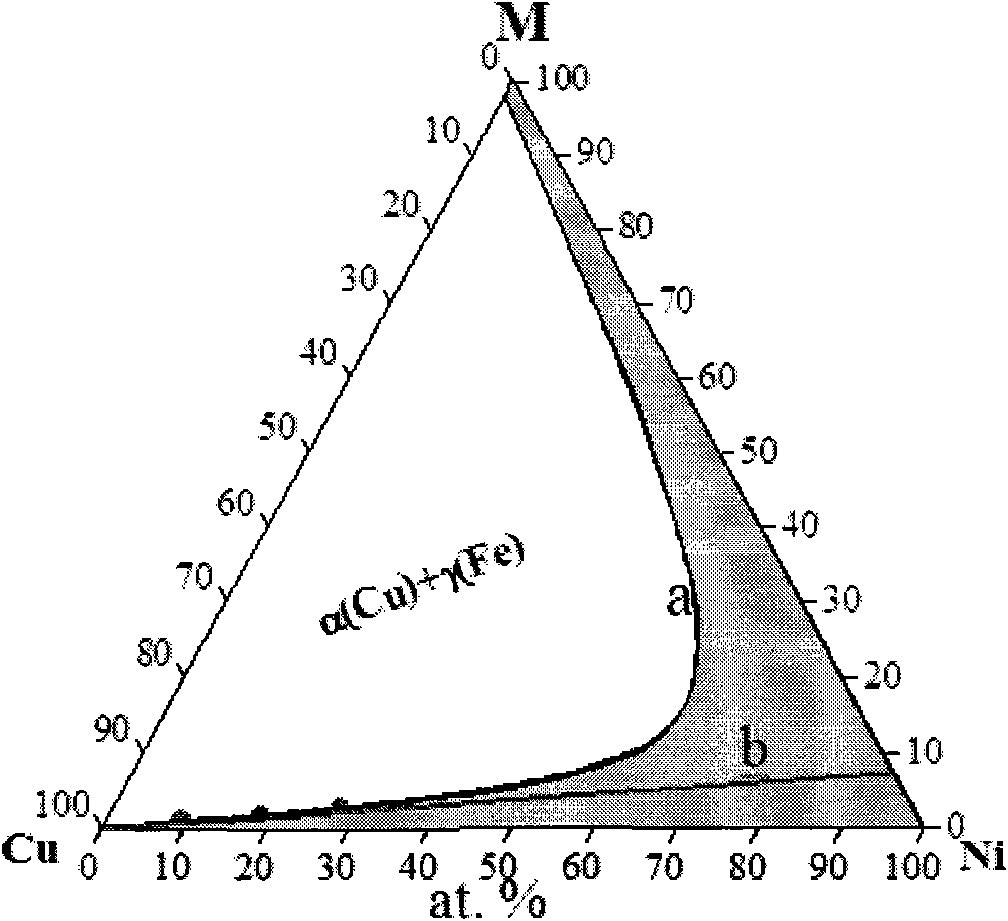

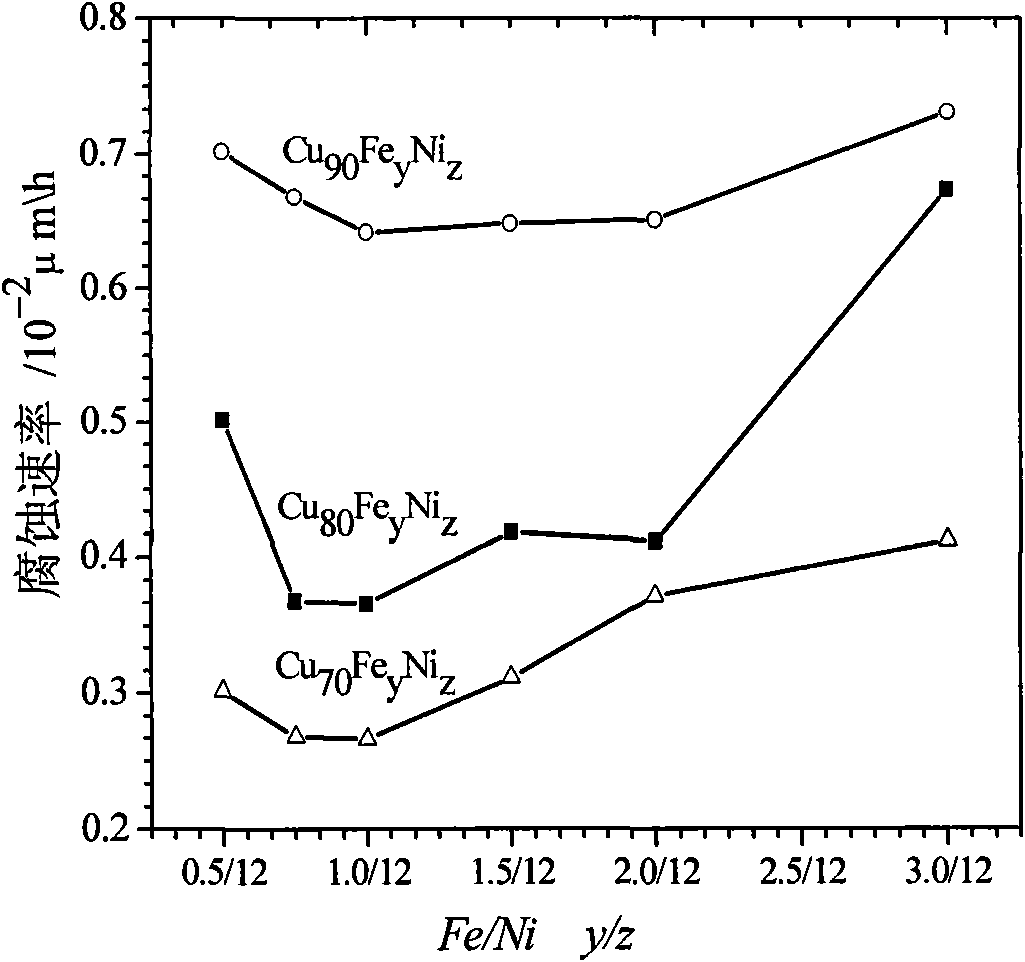

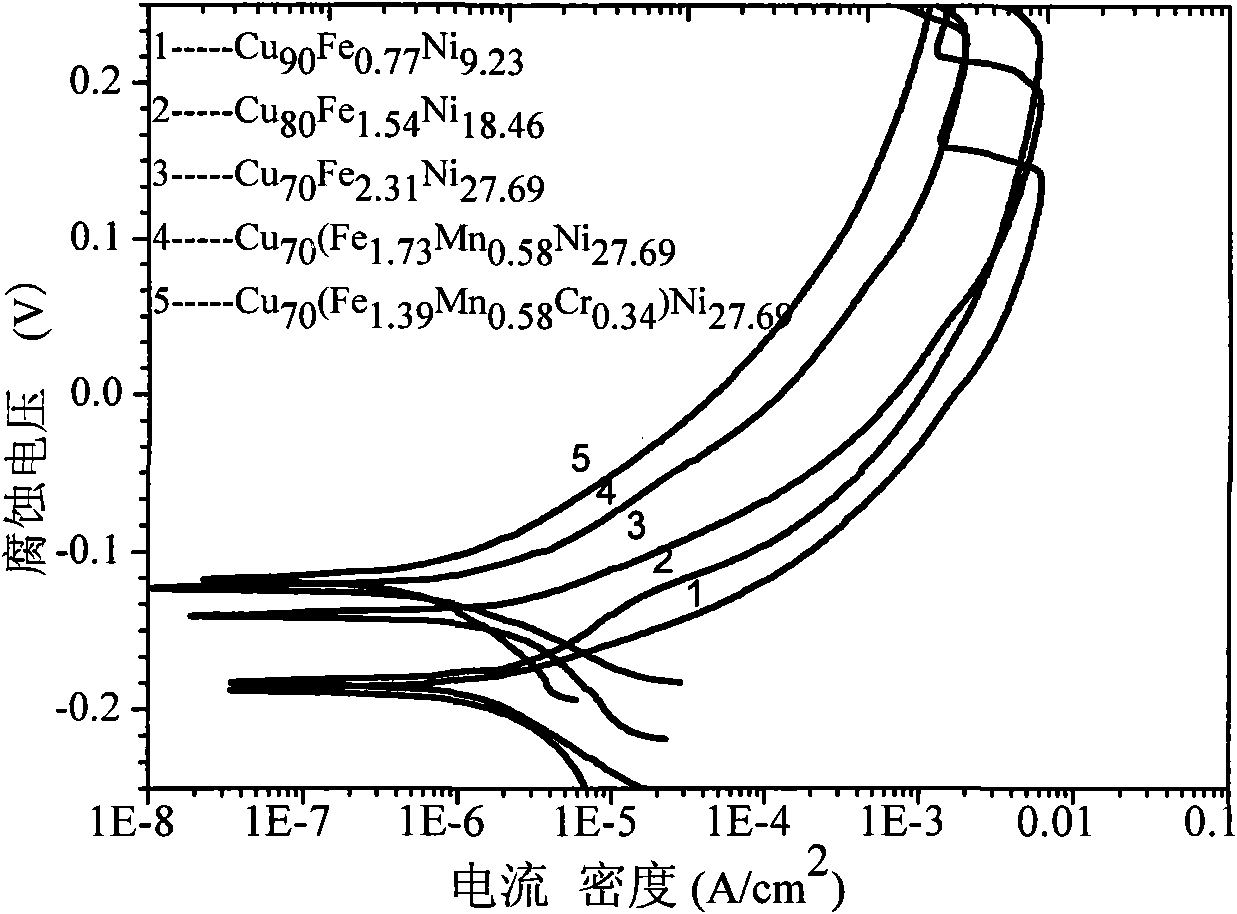

[0033] Example 1 Cu 90 m y Ni z Preparation of Solid Solution Alloy and Its Corrosion Resistance Test

[0034] 1. Preparation of Cu 90 m y Ni z Alloy (y / z=0.5 / 12, 0.75 / 12, 1 / 12, 1.5 / 12, 2 / 12, and y+z=10%) alloy mixture. Convert the atomic percentage in the above alloy into weight percentage, mix the mixture, put the proportioned mixture in the water-cooled copper crucible of the electric arc melting furnace, and use non-consumable arc melting under the protection of argon to melt, The smelting current is 200A. After the smelting is completed, it is turned over and placed in the water-cooled copper crucible again for the second smelting. Repeat the smelting for at least 5 times to obtain an alloy with uniform composition.

[0035] 2. Add Cu 90 m y Ni z After the alloy was kept in solid solution at 800°C for 5 hours in a vacuum annealing furnace, the sample was taken out and quenched in water to obtain a solid solution alloy with uniform composition after heat treatment...

Embodiment 2

[0038] Example 2 Cu 80 m y Ni z Alloy (y / z=0.5 / 12, 0.75 / 12, 1 / 12, 1.5 / 12, 2 / 12, and y+z=20%) preparation and corrosion resistance test

Embodiment 3

[0039] Example 3 Cu 70 m y Ni z Alloy (y / z=0.5 / 12, 0.75 / 12, 1 / 12, 1.5 / 12, 2 / 12, and y+z=30%) preparation and corrosion resistance test

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com