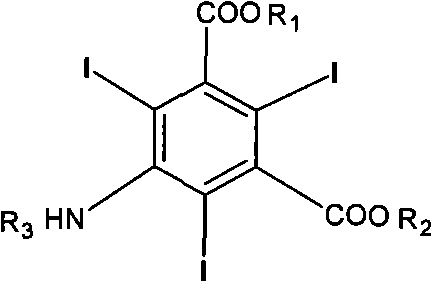

Method for recovering iodine in production waste liquid of X-CT series contrast media

A recovery method and contrast agent technology, applied to chemical instruments and methods, iodine, iodine/hydrogen iodide, etc., to achieve the effects of simple operation, low cost, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Get the black production waste liquid 300mL (with I + Calculated, containing iodine 3.5%) in the normal pressure reflux device, directly heated and digested and refluxed for 1.0h, cooled to room temperature in a water bath, collected the iodine element attached to the wall of the condensation tube, and the yield was about 31.3%. Control the temperature of the solution in the reactor at 0°C, and add 3.5g Na in batches under stirring. 2 SO 3 , determined the end point of the reduction reaction by the potentiometric monitoring method, allowed to stand for 20 minutes, filtered, and collected the solid iodine element, and the yield was about 40.4%. Put the filtrate back into the reactor, slowly add 6 mL of 30% H 2 o 2 , the end point of the oxidation reaction was determined by the potentiometric monitoring method, and granular solids were precipitated, and filtered after standing for 20 minutes to collect solid iodine, with a yield of about 12.1%. Put the filtrate back i...

Embodiment 2

[0035] Get the production waste liquid of 300mLX-CT series contrast agent iodination reaction (black, with I + Calculated, containing iodine 3.2%) in the normal pressure reflux device, direct heating, cooking and reflux treatment for 1.0h, cooling to room temperature in a water bath, collecting iodine simple substance attached to the wall of the condensation tube, the yield is about 30.2%. Use the waste liquid after the above treatment as catholyte, lead plate as cathode, externally connect salt bridge, water as anolyte, lead dioxide as anode, control cathode current density 5mA / cm 2 , electroreduction treatment under stirring for 1 h, standing and filtering, and collecting solid iodine simple substance, the yield is about 39.7%. Then use the filtrate as the anolyte, lead dioxide as the anode, externally connect the salt bridge, water as the catholyte, lead plate as the cathode, and control the anode current density to 10mA / cm 2 , electrooxidized for 30 minutes under stirring...

Embodiment 3

[0037] Get the production waste liquid of 400mLX-CT series contrast agent iodination reaction (black, with I + Calculated, containing iodine 3.9%) in the normal pressure reflux device, directly heated and digested and refluxed for 1.5h, cooled to room temperature in a water bath, collected the iodine element attached to the wall of the condensation tube, and the yield was about 32.7%. Control the temperature of the solution in the reactor at -10°C, add 3.3g NaHSO in batches under stirring 3 , determined the end point of the reduction reaction by the potentiometric monitoring method, allowed to stand for 30 minutes, filtered, and collected the solid iodine element, and the yield was about 38.4%. The filtrate was put back into the reactor, and 8 mL of 30% H was slowly added dropwise under stirring. 2 o 2 , determined the end point of the oxidation reaction by the potentiometric monitoring method, precipitated granular solids, filtered after standing for 30 minutes, and collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com