Electrode materials of composite rare-earth iridium alloy and sparking plug of using the electrode materials

A technology of composite rare earth and alloy electrodes, which is applied in the field of spark plugs, can solve the problems of difficult price advantage, insignificant improvement of processing performance, high material cost, etc., achieve superior cost performance, improve high temperature acid corrosion resistance, and improve overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) The surface hardness of the finished electrode material wire material obtained in this embodiment is 150-160Hv (Φ0.5mm), and the tensile strength is 2250-2550N / mm 2 , the elongation is 5%.

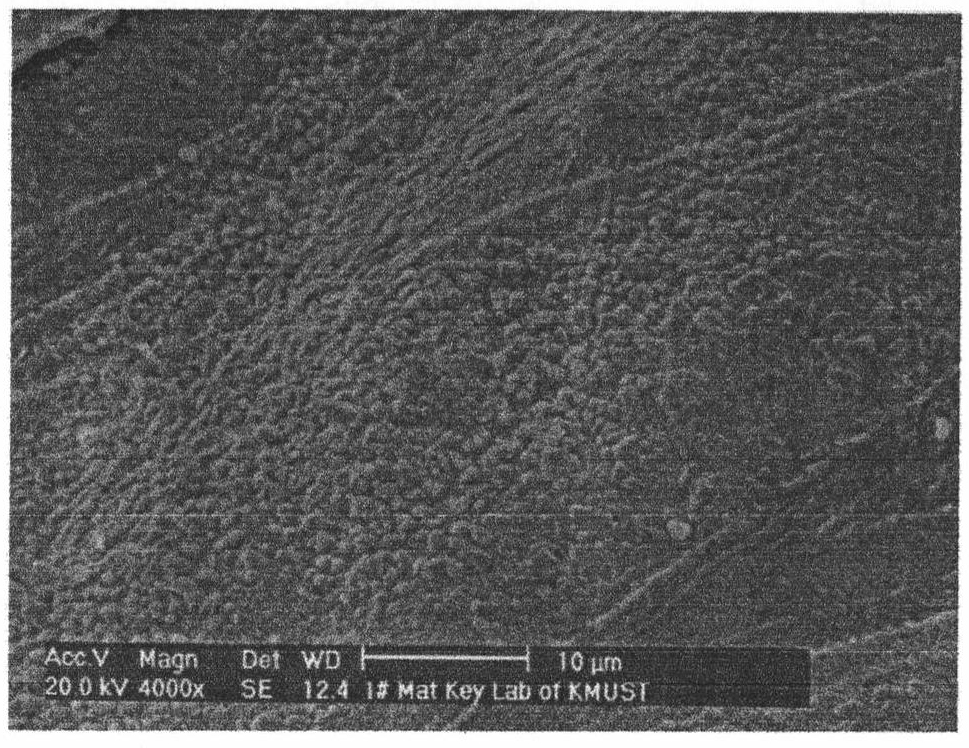

[0028] (2) The tensile fracture is mainly along the grain boundary, and the energy spectrum detection shows that the fracture along the grain boundary contains a certain amount of oxygen, calcium and carbon. Such as figure 1 As shown, there are obvious oxide particles precipitated in the microstructure, and the particle size is small.

[0029] In the spark plug in this embodiment, the ignition tips of the central electrode and the side electrode are the above-mentioned wire material alloys in this embodiment.

Embodiment 2

[0031] (1) The surface hardness of the finished electrode material wire obtained in this example is 160-170Hv (Φ0.5mm), and the tensile strength is 2050-2250N / mm 2 , the elongation is 3%.

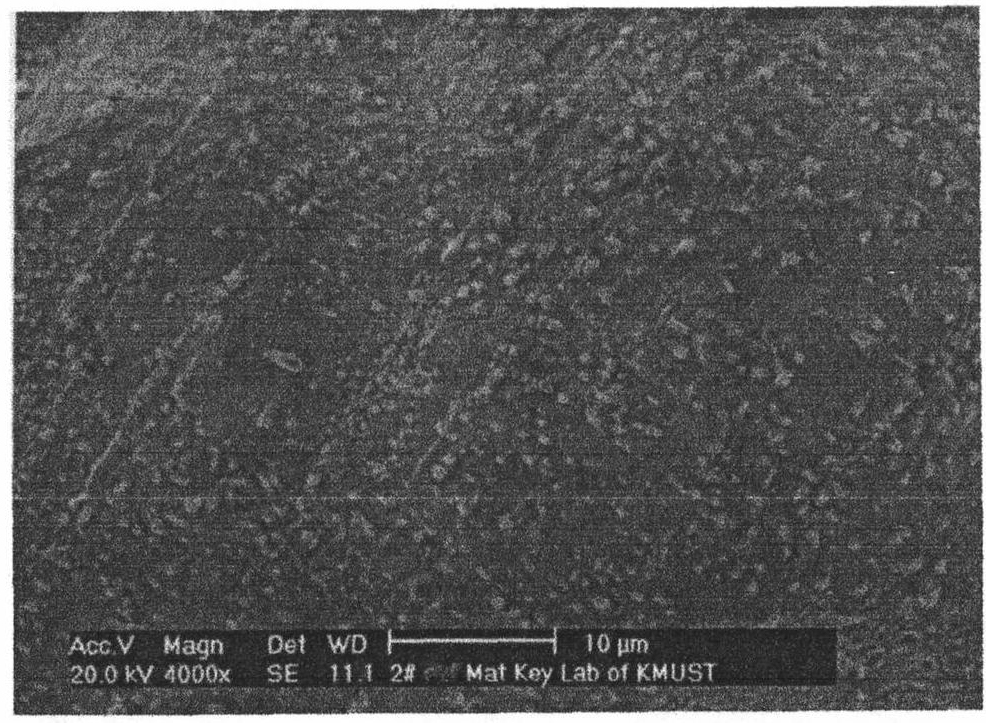

[0032] (2) The tensile fracture is mainly along the grain boundary, and the energy spectrum detection shows that the oxygen content in the fracture along the grain boundary is high. Such as figure 2 As shown, there are obvious oxide particles precipitated in the microstructure, because the addition of rare earth elements is more, so there are more precipitated oxide particles.

[0033] In the spark plug in this embodiment, the ignition tips of the central electrode and the side electrode are the above-mentioned wire material alloys in this embodiment.

Embodiment 3

[0035] (1) The surface hardness of the finished electrode material wire material obtained in this embodiment is 150-160Hv (Φ0.5mm), and the tensile strength is 2250-2550N / mm 2 , the elongation is 8%.

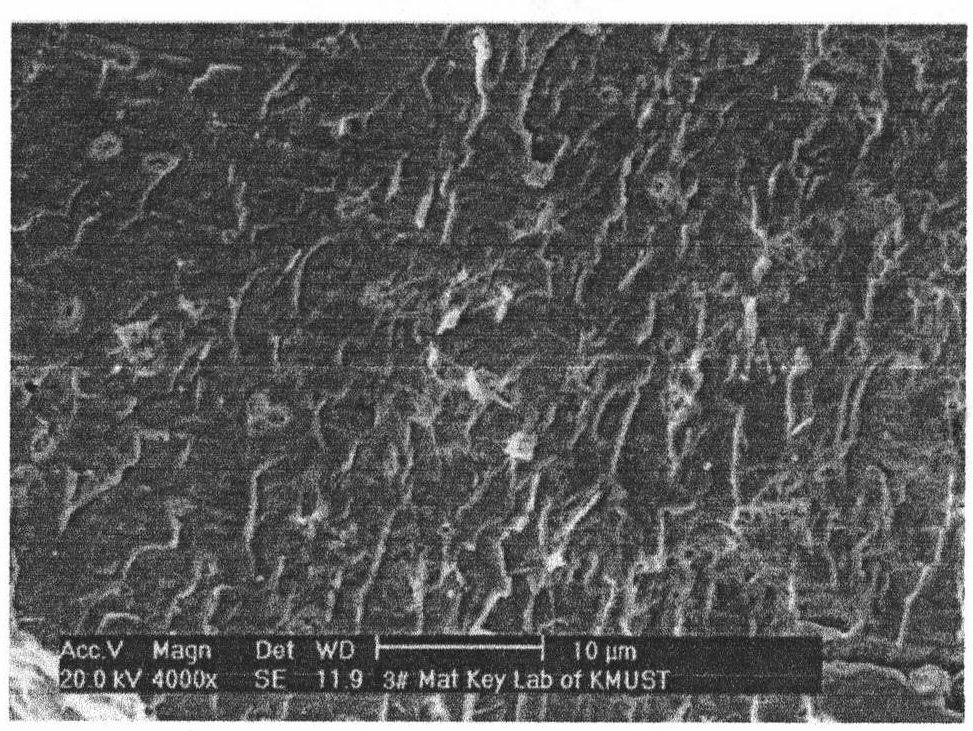

[0036] (2) The tensile fracture is mainly along the grain boundary, and the energy spectrum detection shows that the fracture along the grain boundary contains a certain amount of oxygen. Such as image 3 As shown, with the addition of Th and Al elements, it can be clearly seen that bright white metal elements are precipitated at the grain boundaries and distributed along the grain boundaries, which is conducive to the strengthening of the grain boundaries, which illustrates the obtained in this implementation. The composite rare earth iridium alloy, adding an appropriate amount of rare earth elements and trace metal elements, can eliminate impurities and improve the physical and processing properties of the material.

[0037] In the spark plug in this embodiment, the ignition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com