Nickel-base alloy for nuclear power equipment and manufacturing method for nickel-base-alloy hot rolled plate

A technology of nickel-based alloy and manufacturing method, which is applied in the field of nickel-based corrosion-resistant alloy plate manufacturing, and can solve the problems of lack of patent documents and introductions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

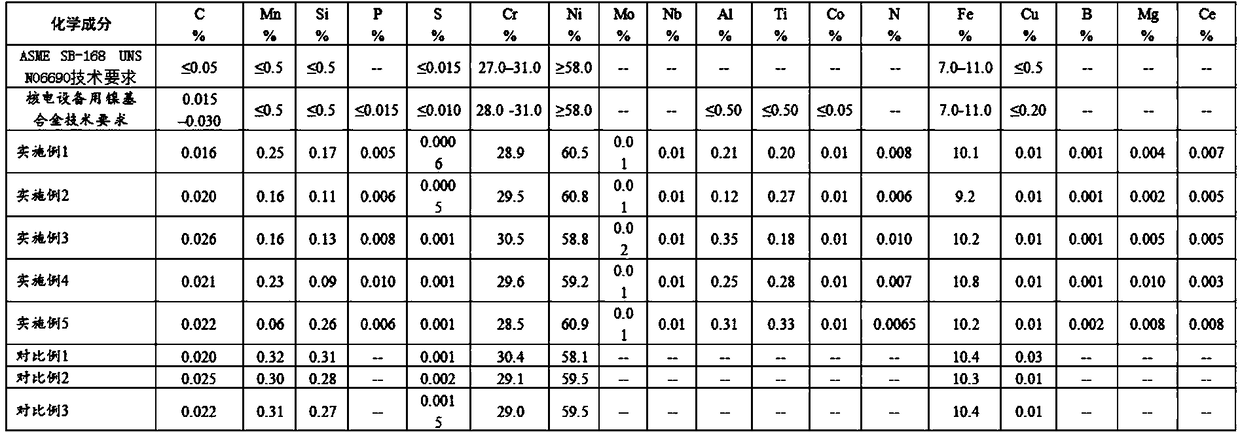

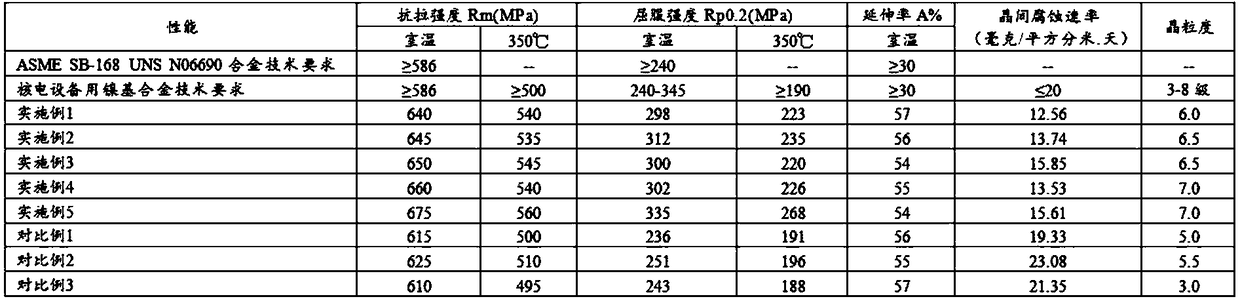

[0065] According to the composition described in the content of the present invention, the alloy electrode rod is cast by vacuum induction melting, and the electroslag remelting furnace is protected by argon gas, and remelted into a large electroslag remelting steel ingot with a weight of more than 10 tons, and the obtained alloy composition is shown in Table 3. Show.

[0066] The large electroslag remelted steel ingot is heated and held at 1130°C for 7 hours, then out of the furnace for forging, upsetting twice, and the deformation is guaranteed to be (30±5)% per drawing, and forged into a square slab suitable for rolling.

[0067] The slab is kept in the heating furnace at 1090°C for 5 hours to roll the steel coil. The starting rolling temperature is 1050°C and the final rolling temperature is 920°C, and rolled into a plate with a thickness of 90mm, a width of 2250mm and a length of 5800mm.

[0068] The solution heat treatment temperature is 1035°C, and the heat preservation...

Embodiment 2

[0071] According to the composition described in the content of the present invention, the alloy electrode rod is cast by vacuum induction melting, and the electroslag remelting furnace is protected by argon gas, and remelted into a large electroslag remelting steel ingot with a weight of more than 10 tons, and the obtained alloy composition is shown in Table 3. Show.

[0072] The large electroslag remelted steel ingot is heated and held at 1190°C for 10 hours, then out of the furnace for forging, upsetting 3 times, and the deformation is guaranteed to be (40±5)% per drawing, and forged into a square slab suitable for rolling.

[0073] The slab is kept in a heating furnace at 1160°C for 6 hours to roll the steel coil. The starting rolling temperature is 1100°C and the final rolling temperature is 1010°C, and rolled into a plate with a thickness of 82mm, a width of 2500mm, and a length of 5200mm.

[0074] The solution heat treatment temperature is 1060°C, and the heat preservat...

Embodiment 3

[0077] According to the composition described in the content of the present invention, the alloy electrode rod is cast by vacuum induction melting, and the electroslag remelting furnace is protected by argon gas, and remelted into an electroslag remelting steel ingot weighing more than 5 tons, and the obtained alloy composition is shown in Table 3. .

[0078] The electroslag remelted steel ingot is heated and held at 1210°C for 6 hours, then out of the furnace for forging, upsetting once, and the deformation is guaranteed to be (35±5)% per drawing, and forged into a square slab suitable for rolling.

[0079] The slab is kept in a heating furnace at 1200°C for 5 hours to roll the steel coil. The starting rolling temperature is 1100°C, the final rolling temperature is 1000°C, and rolled into a plate with a thickness of 40mm, a width of 1200mm, and a length of 8100mm.

[0080] The solution heat treatment temperature is 1080°C, and the heat preservation is 65min; the aging heat tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com