Mg-based composite hydrogen storage material containing alkaline earth metals-aluminum hydride and preparation method thereof

A technology of hydrogen storage materials and aluminum hydrides, which is applied in the field of hydrogen storage materials to achieve the effects of high hydrogen absorption and desorption cycle stability, high hydrogen storage capacity, and good low-temperature hydrogen absorption kinetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

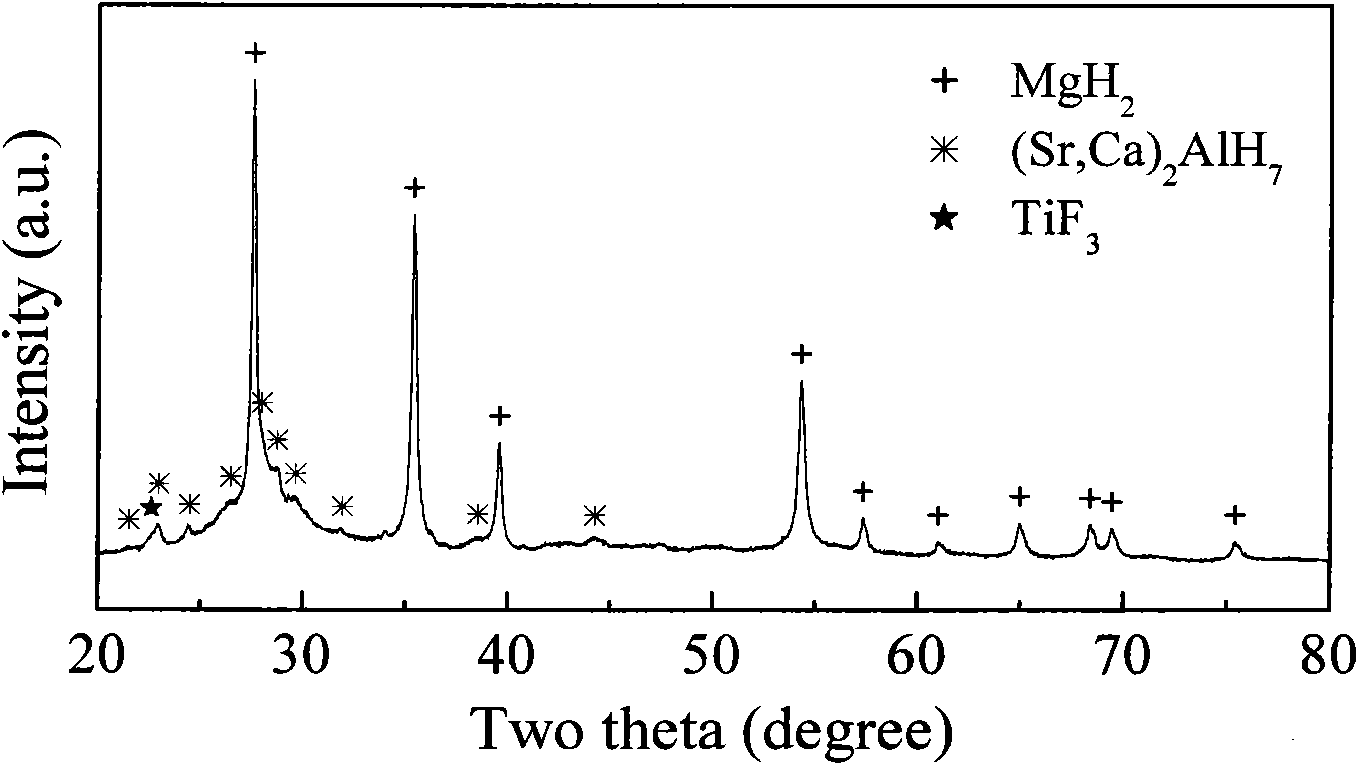

[0017] Example: According to MgH 2 +30wt.% (Sr 0.8 Ca 0.2 ) 2 H 7 +5wt.%TiF 3 The design composition, accurately weigh MgH 2 , (Sr 0.8 Ca 0.2 ) 2 H 7 and TiF 3 The three raw material powders are poured into a stainless steel ball mill tank with a volume of 250ml and mixed. At the same time, stainless steel balls with a diameter of 10mm are put into the ball mill tank, and the ball-to-material ratio is 20:1; After argon cleaning was repeated 3 times, 0.5MPa hydrogen was filled as a protective atmosphere, and the mixed powder was mechanically milled with a planetary ball mill at a milling speed of 400 rpm and a milling time of 10 hours. The X-ray diffraction pattern of the composite hydrogen storage material obtained after ball milling is as follows: figure 1 As shown, it can be seen that the composite hydrogen storage material is mainly composed of MgH 2 , (Sr, Ca) 2 H 7 and TiF 3 Composed of three phases.

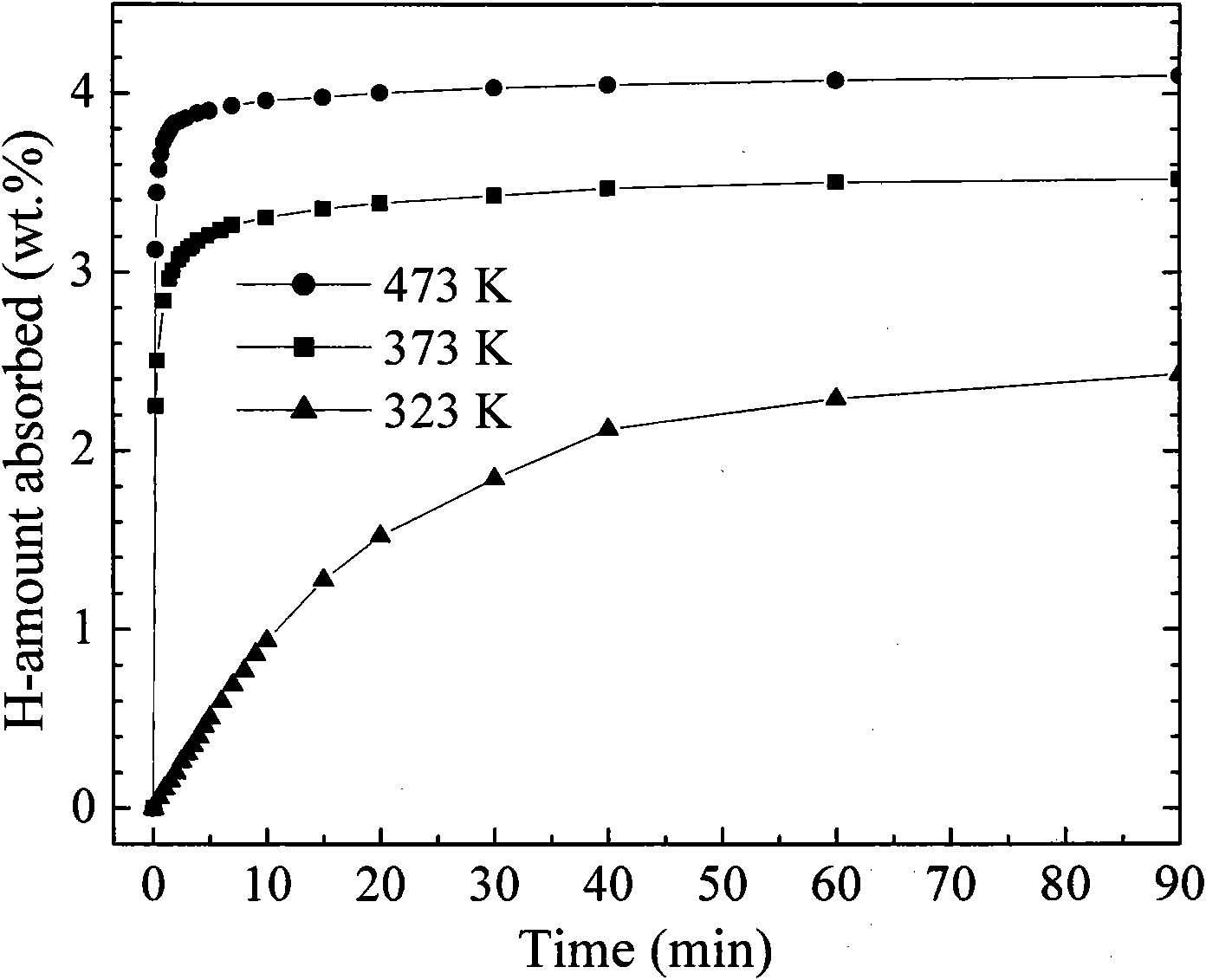

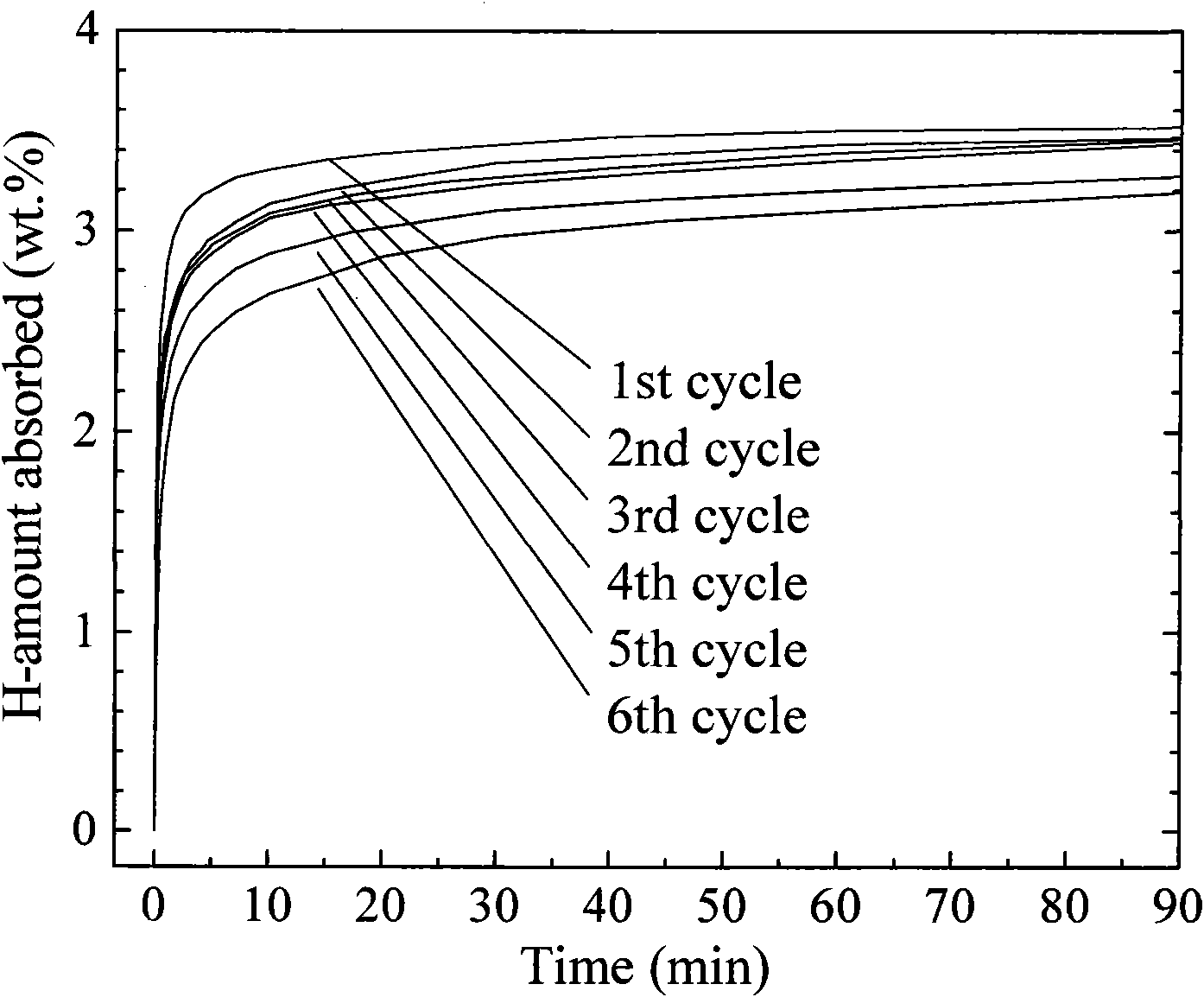

[0018] Under the initial hydrogen pressure of 1 MPa an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com