Process of using sulphur lead-zinc containing tailings to prepare sulphur iron ore concentrate

A technology of tailings and concentrates, applied in the direction of sulfur trioxide/sulfuric acid, chemical instruments and methods, wet separation, etc., to achieve the effects of reduced environmental impact, not easy to oxidize, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

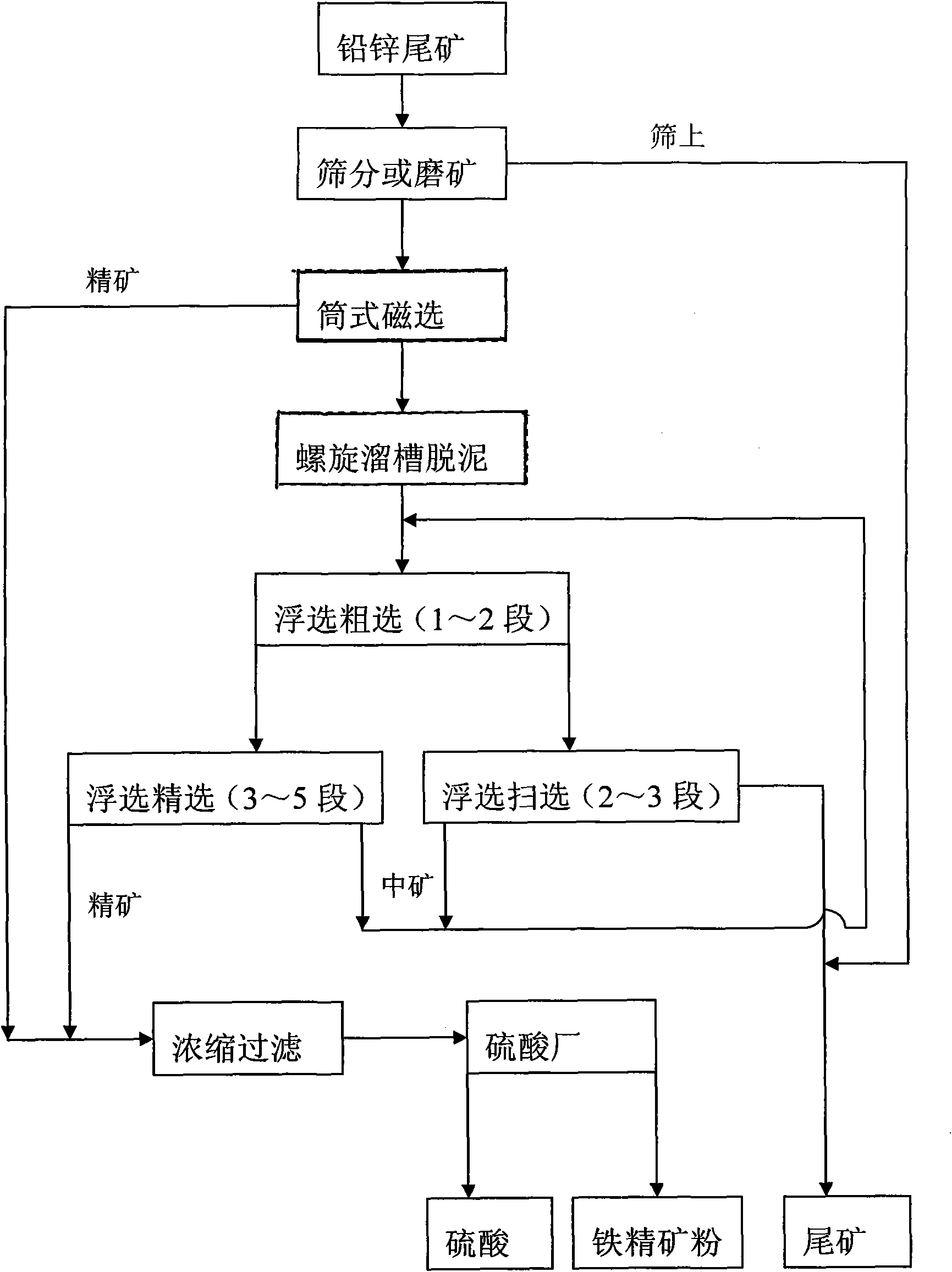

Image

Examples

Embodiment 1

[0019] Example 1. The tailings after flotation of lead and zinc in a lead-zinc ore dressing plant contain 7.50% sulfur and 10.82% iron. The sulfur-containing minerals are mainly pyrite and pyrrhotite, and the iron-containing minerals are mainly pyrite , pyrrhotite and a small amount of magnetite. Use a sieving machine to screen out the +0.15mm particle size, and the products under the sieve are pre-selected by a drum magnetic separator after pulping in a mixing tank, and the iron content is 50.30%, the sulfur content is 41.50%, the iron recovery rate is 42.16%, and the sulfur recovery rate is 35.68%. Magnetic separation of pyrite concentrate. The magnetic separation tailings contain 38% mud, and the spiral chute is used to remove the mud and throw the tails. The coarse concentrate is mixed with a mixing tank for flotation, and 2500g / t sulfuric acid is added to adjust the pH of the slurry to 5.5. 60g / t of terpineol oil was added as a foaming agent. After one roughing, two swee...

Embodiment 2

[0020] Example 2. The tailings after flotation of lead and zinc in a lead-zinc ore dressing plant contain an average of 12.80% sulfur and 11.18% iron. The sulfur-containing minerals are mainly pyrite, and the iron-containing minerals are also pyrite and pyrrhotite and the total amount of magnetite <1%. Due to the long storage time, the surface of pyrite minerals may be oxidized. Grind the tailings with a φ2100×2700 ball mill. The mud content of the product after grinding is 26%. Use a mixing tank to adjust the slurry and then carry out flotation. Add 3200g / t sulfuric acid to adjust the pH of the slurry to 5.5. Add butyl yellow 200g / t of pine oil, 80g / t of pine alcohol oil was added, and after two times of roughing, three times of sweeping and five times of beneficiation, 48.62% of sulfur, 42.47% of iron, 90.89% of sulfur and iron mixed grades were obtained, sulfur and iron The recovery rate of the pyrite concentrate is 88.87%, and the sulfur content of the final tailings afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com