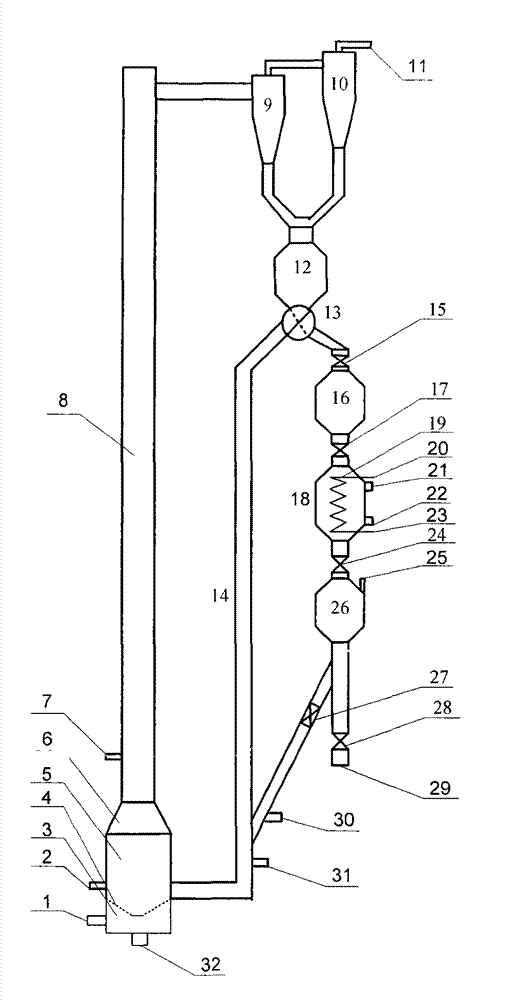

Method and device for thermally desulfurizing by synthesis gas dry method and reclaiming sulfur

A synthesis gas and sulfur recovery technology, applied in the direction of sulfur preparation/purification, catalytic conversion gas purification of impurities, etc., can solve the problems of complex desulfurizer regeneration and sulfur recovery operations, unsuitable for continuous industrial production applications, etc., to achieve The process structure is simple and reasonable, the wear is small, and the operation stability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The fast fluidized bed desulfurization reactor is 16000mm high, the inner diameter of the upper straight pipe section is 50mm, and the inner diameter of the lower expanded section is 80mm. The height of the desulfurizer regeneration reactor is 1500mm, and the inner diameter is 200mm. The desulfurizer is an amorphous activated carbon desulfurizer with a particle size of 150-500μm and a bulk density of 0.65g / ml. Composition of oxygen blast fluidized bed gasification synthesis gas (volume percentage): H 2 content 28%, CO content 25%, N 2 Content 6%, CH 4 Content 1%, CO 2 Content 16%, H 2 O content 24%, H 2 S concentration 2800-3200mg / m 3 , COS concentration 10-20mg / m 3. The operating temperature of the desulfurization reactor is 160-180°C, the pressure is 1.0MPa, the apparent operating gas velocity is 1.0-1.8m / s, the oxygen-sulfur ratio is 0.45-0.55, and the operating temperature of the desulfurization agent regeneration reactor is 380-400°C. First, desulfurizer p...

Embodiment 2

[0028] The desulfurizing agent is an activated carbon desulfurizing agent loaded with iron, the loading amount of iron oxide is 0.5%, the particle size is 200-500 μm, and the bulk density is 0.65 g / ml. Using air blast fluidized bed gasification to produce synthesis gas, the composition of synthesis gas is (volume percentage): H 2 content 15%, CO content 13%, N 2 Content 46%, CH 4 Content 1%, CO 2 Content 10%, H 2 O content 15%, H 2 S concentration 1500-1800mg / m 3 , COS concentration 10-20mg / m 3 . The operating temperature of the desulfurization reactor is 160-180°C, the pressure is 0.6MPa (table), the operating gas velocity is 1.8-2.0m / s, and the oxygen-sulfur ratio is 0.45-0.55. The operating temperature of the desulfurizer regeneration reactor is 420-450°C, with 450°C superheated steam as the regeneration gas, and the rest are the same as in Example 1. After desulfurization and purification, the sulfide content in the syngas is 25-35mg / m 3 , The elemental sulfur con...

Embodiment 3

[0030] The desulfurizing agent is an activated carbon desulfurizing agent loaded with iron, with an iron oxide load of 0.5%, a particle size of 200-500 μm, and a bulk density of 0.65 g / ml. Using air blast fluidized bed gasification to produce synthesis gas, the composition of synthesis gas is (volume percentage): H 2 content 15%, CO content 13%, N 2 Content 46%, CH 4 Content 1%, CO 2 Content 10%, H 2 O content 15%, H 2 S concentration 1500-2000mg / m 3 , COS concentration 10-20mg / m 3 . The operating temperature of the desulfurization reactor is 180-210°C, the pressure is 1.3MPa (table), the operating gas velocity is 1.2-1.5m / s, and the oxygen-sulfur ratio is 0.5-0.6. The operating temperature of the desulfurizer regeneration reactor is 420-450°C, with 450°C superheated steam as the regeneration gas, and the rest are the same as in Example 1. After desulfurization and purification, the sulfide content in the syngas is 45-75mg / m 3 , The elemental sulfur content of desulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com