Ultra-hydrophobic nanometer SiO2/high polymer complex film and preparation method thereof

A technology of high polymer and composite film, applied in the field of super-hydrophobic nano-SiO2/polymer composite film and its preparation, can solve the problems of lack of strength, easy gelation, loss of flow properties, etc., and achieve good film-forming performance, Simple process, the effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

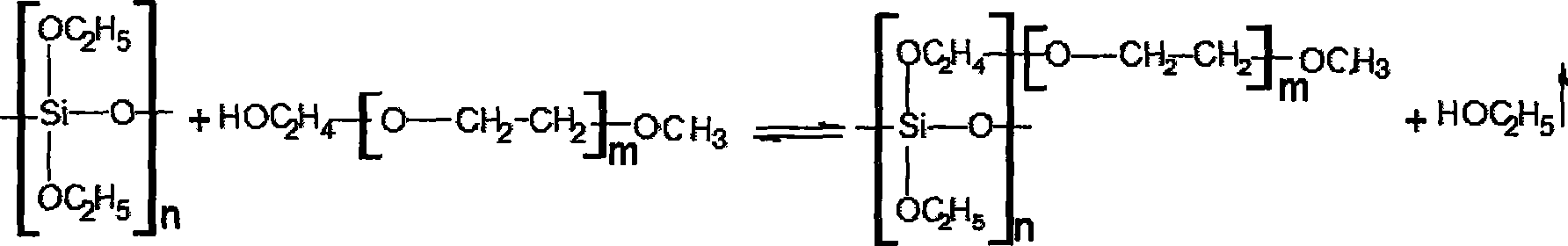

Method used

Image

Examples

Embodiment 1

[0023] Put 100g of PEDS (viscosity at 1,000cp) and 100g of MPEG (molecular weight: 1,000) into a 500ml three-necked flask and stir evenly, and carry out transesterification at 70°C for 3 hours. At the same time, under 4.0KPa reduced pressure, the The product ethanol was extracted to obtain the MPEG-g-PEDS graft polymer. Dissolve 7.5g of water in 20ml of ethanol, add it to a three-neck flask, stir vigorously for 10 minutes, pour it into a 1,000ml beaker, and after about 30 minutes, the gel solidifies, then crushes the gel, puts it in a vacuum drying oven, and Aging at 110°C for 4 hours while continuously extracting product ethanol to obtain SiO 2 wet gel. Weigh 50g SiO2 2 The wet gel was mixed with 50 g of toluene, and the SiO 2 The wet gel was dispersed in toluene to prepare a slurry, and the ball milling time was 6 hours. the SiO 2 The wet gel particle dispersion slurry is mixed evenly with 500 g of polystyrene (PS) / toluene solution with a mass concentration of 10%, and ...

Embodiment 2

[0025]Put 100g of PEDS (viscosity at 5,000cp), 100g of MPEG (molecular weight of 1,000), and 100ml of ethanol into a 500ml three-necked flask and stir evenly. After transesterification at 65°C for 4 hours, start to depressurize at 8.0KPa Extraction, part of the product ethanol is extracted. Dissolve 5g of water in 20ml of ethanol, add it to a three-neck flask, stir vigorously for 10 minutes, pour it into a 1,000ml beaker, after about 20 minutes, the gel solidifies, then crush the gel, put it in a vacuum drying oven, and dry it at 130 ℃ aging for 5 hours while continuously extracting the product ethanol to obtain SiO 2 wet gel. Weigh 50g SiO2 2 The wet gel was mixed with 50 g of toluene, and the SiO 2 The wet gel was dispersed in toluene to prepare a slurry, and the ball milling time was 8 hours. the SiO 2 The wet gel particle dispersion slurry is mixed evenly with 1,000 g of 10% polystyrene (PS) / toluene solution, then coated on the substrate, and dried to form a film unde...

Embodiment 3

[0027] Put 100g of PEDS (viscosity at 1,000cp) and 200g of MPEG (molecular weight: 400) into a 500ml three-necked flask and stir evenly. After transesterification at 60°C for 2 hours, extract under reduced pressure at 3.0KPa at the same time. Extract part of the product ethanol to obtain MPEG-g-PEDS graft polymer. Dissolve 7g of water in 20ml of ethanol, add it to a three-necked flask, stir vigorously for 10 minutes, pour it into a 1,000ml beaker, and after about 20 minutes, the gel solidifies, then crush the gel, put it in a vacuum drying oven, and dry it at 120 ℃ aging for 6 hours while continuously extracting the product ethanol to obtain SiO 2 wet gel. Weigh 50g SiO2 2 The wet gel was mixed with 50 g of toluene, and the SiO 2 The wet gel was dispersed in toluene to prepare a slurry, and the ball milling time was 7 hours. the SiO 2 Wet gel particle dispersion slurry and 700g mass concentration are 10% styrene-butadiene-styrene (SBS) / toluene solution and mix uniformly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com