Preparation method of energetic film composite type gunpowder

A compound and explosive technology, applied in explosives, explosive charges, explosives processing equipment, etc., to achieve the effects of small specific surface area, increased energy output, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. The raw materials are TNT and aluminum film strips with a width of 30cm, a length of 5m and a thickness of 0.02mm.

[0022] 2. Put TNT into a water bath and heat it to 80°C to 90°C to melt it into a molten state.

[0023] 3. Evenly coat molten TNT on one side of the aluminum film surface, then directly roll the TNT-coated aluminum film explosive into a cylindrical structure roll, and obtain a cylindrical high-energy film composite explosive (TNT / Al) after solidification .

[0024] In this embodiment, no additives are used, that is, the high-energy thin-film composite propellant and explosive consists only of aluminum thin film and TNT charge. For the needs of the test, in the prepared high-energy film composite propellant, the mass content of the aluminum film is 4%, 10%, 20%, 30%, 40% respectively.

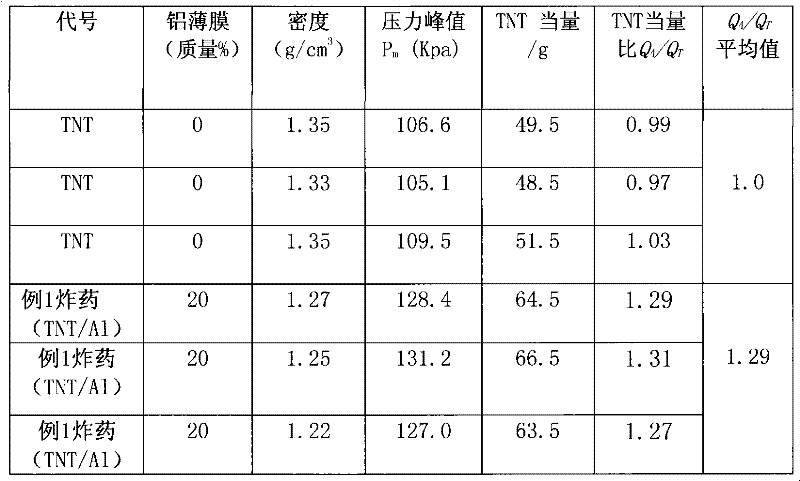

[0025]4. Use the steel plate indentation test method to verify the detonation, detonation transmission and violence of the high-energy film composite propellant prepa...

Embodiment 2

[0034] 1. Mix RDX, paraffin, and graphite in a mass ratio of 95:4:1, and heat to 80°C.

[0035] 2. Apply the heated explosive coating evenly on one side of the aluminum film strip (thickness 0.02mm, width 300mm) to make a sheet-like high-energy thin film composite (RDX / Al) propellant blank.

[0036] 3. Process the sheet-like high-energy film composite propellant and explosive blank into a circular explosive film with a diameter of 25mm, then stack the explosive film layer by layer and put it into a cylindrical mold with a diameter of 25.2mm and pressurize it to 70MPa. After demolding, the stacked Type structured high energy thin film composite explosives

[0037] For the needs of the experiment, in the prepared high-energy thin film composite (TNT / Al) propellant aluminum thin film, the mass content of the aluminum thin film is respectively 10%, 20%, 30%, 40%, 50%, 60%.

[0038] 4. Use the steel plate indentation test to verify the initiation, transmission and severity of the ...

Embodiment 3

[0045] 1. Raw materials: RDX particles, epoxy resin, aluminum film thickness 0.7mm, width 300mm.

[0046] 2. Mix RDX and epoxy resin evenly at a mass ratio of 98:2, put them into a water bath for heating, and mix epoxy resin and RDX evenly to obtain the explosive coating.

[0047] 3. The prepared explosive coating is evenly coated on one side of the surface of the aluminum film (30 cm wide and 40 cm long) to form a sheet-like high-energy film composite (RDX / Al) propellant blank.

[0048] 4. Process the flaky high-energy thin film composite propellant and explosive billet into a circular explosive film with a diameter of 25mm, then stack the explosive film layer by layer into a cylindrical mold with a diameter of 25.2mm and pressurize to 70MPa. After demoulding, the obtained High energy thin film sandwich structure composite explosive grain. The mass content of the high-energy film composite (RDX / Al) explosive aluminum film prepared in the laboratory is 20% and 30% respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com