Automatic quantitative control coal-water oil slurry mixer

A quantitative control and mixer technology, which is applied to mixers, mixers, chemical instruments and methods with rotary stirring devices, etc., can solve the problems of insufficient combustion value, inconvenient storage or transportation, and increased costs, so as to improve combustion efficiency. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

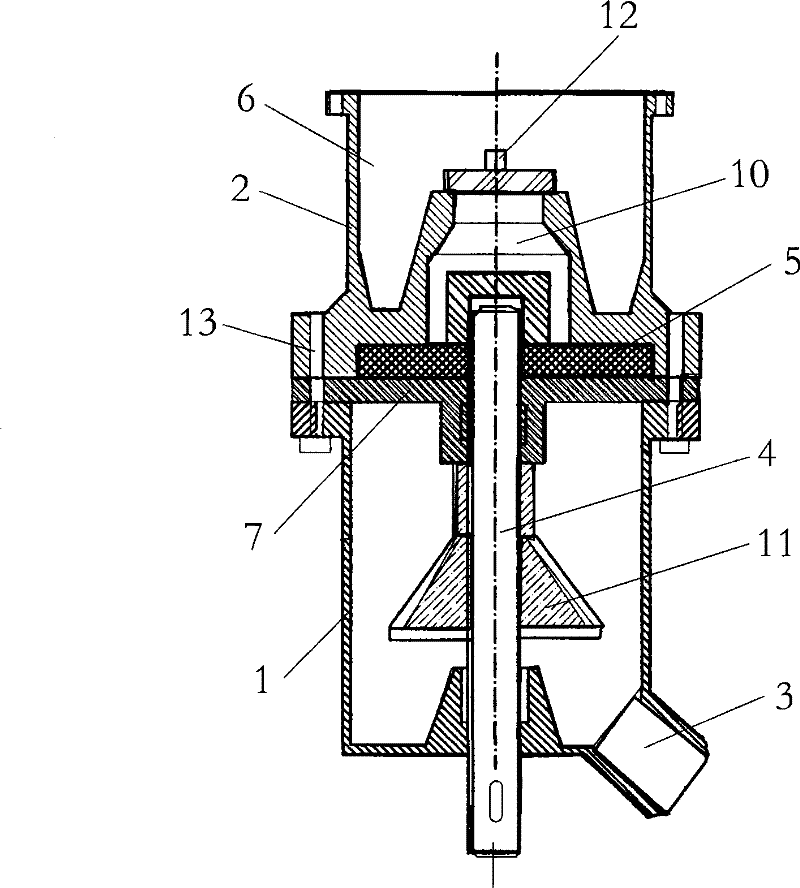

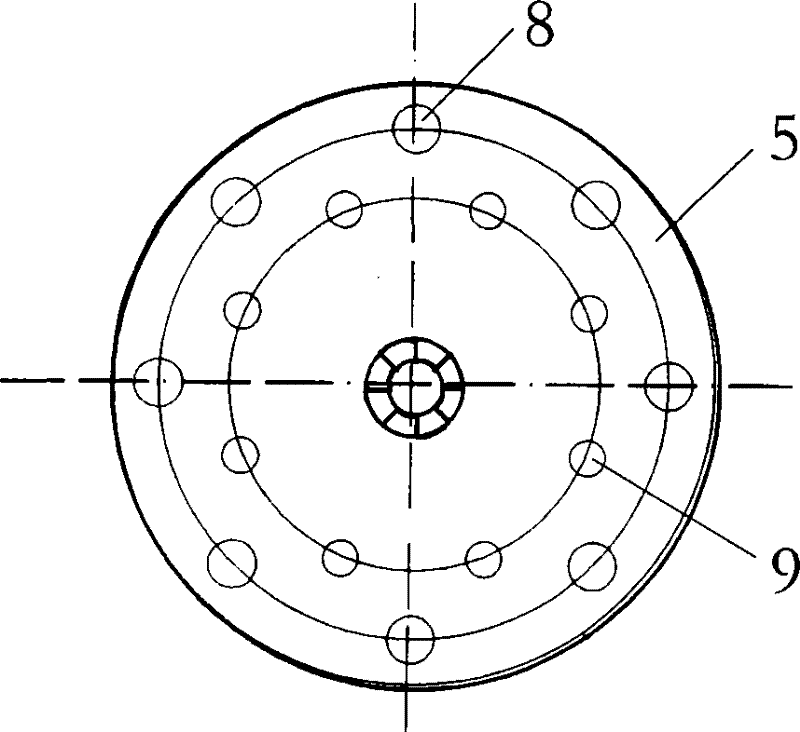

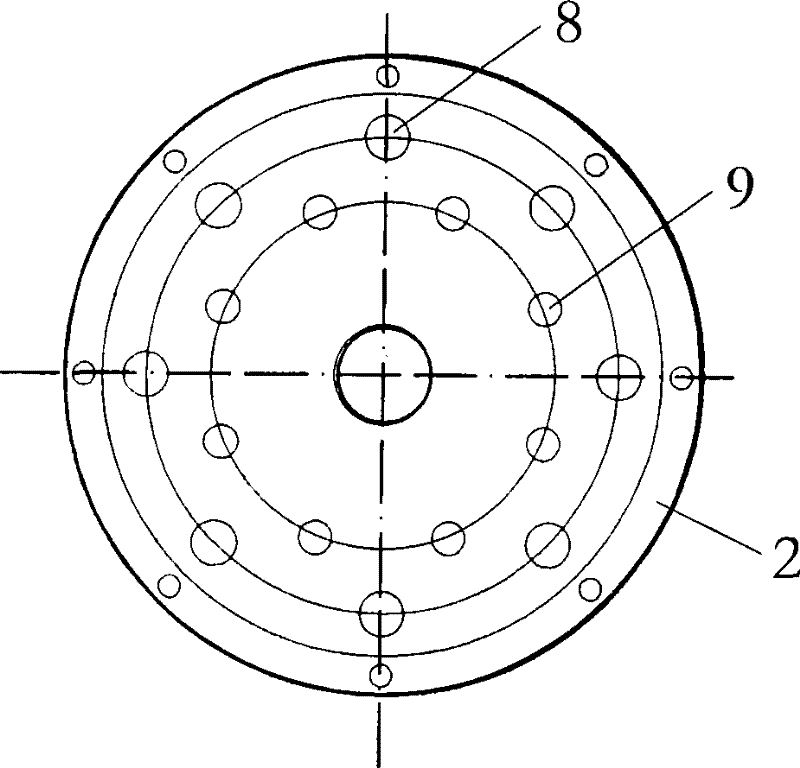

[0017] See Figure 1 to Figure 4 , the specific embodiment of the present invention is as follows: comprises mixer housing 1, and the bottom of housing 1 is provided with a slurry outlet 3, and the key is that the upper end of housing 1 is provided with the pulverized coal chamber 6 that can hold tool to hold pulverized coal. And the upper cover 2 of the emulsion chamber 10 containing the oil-water emulsion, a quantitative control device that can automatically control the amount of coal powder and oil-water emulsion entering is provided between the upper cover 2 and the housing 1, and the quantitative control device and the stirring in the housing 1 When in use, the mixer can be connected with the coal-water slurry feeding device of the burner. When the pulverized coal chamber 6 and the emulsion chamber 10 are respectively connected with the feeding equipment, the coal powder chamber 6 and the emulsion chamber 10 There are coal powder and emulsion in it, which enter the shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com