Wire harness

A wire harness and grounding rod technology, applied in the field of wire harnesses, can solve the problems of reduced shielding effect, damage, and inability to shield the overall uniformity, and achieve the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, embodiments of the present invention (hereinafter referred to as embodiments) will be described with reference to the drawings.

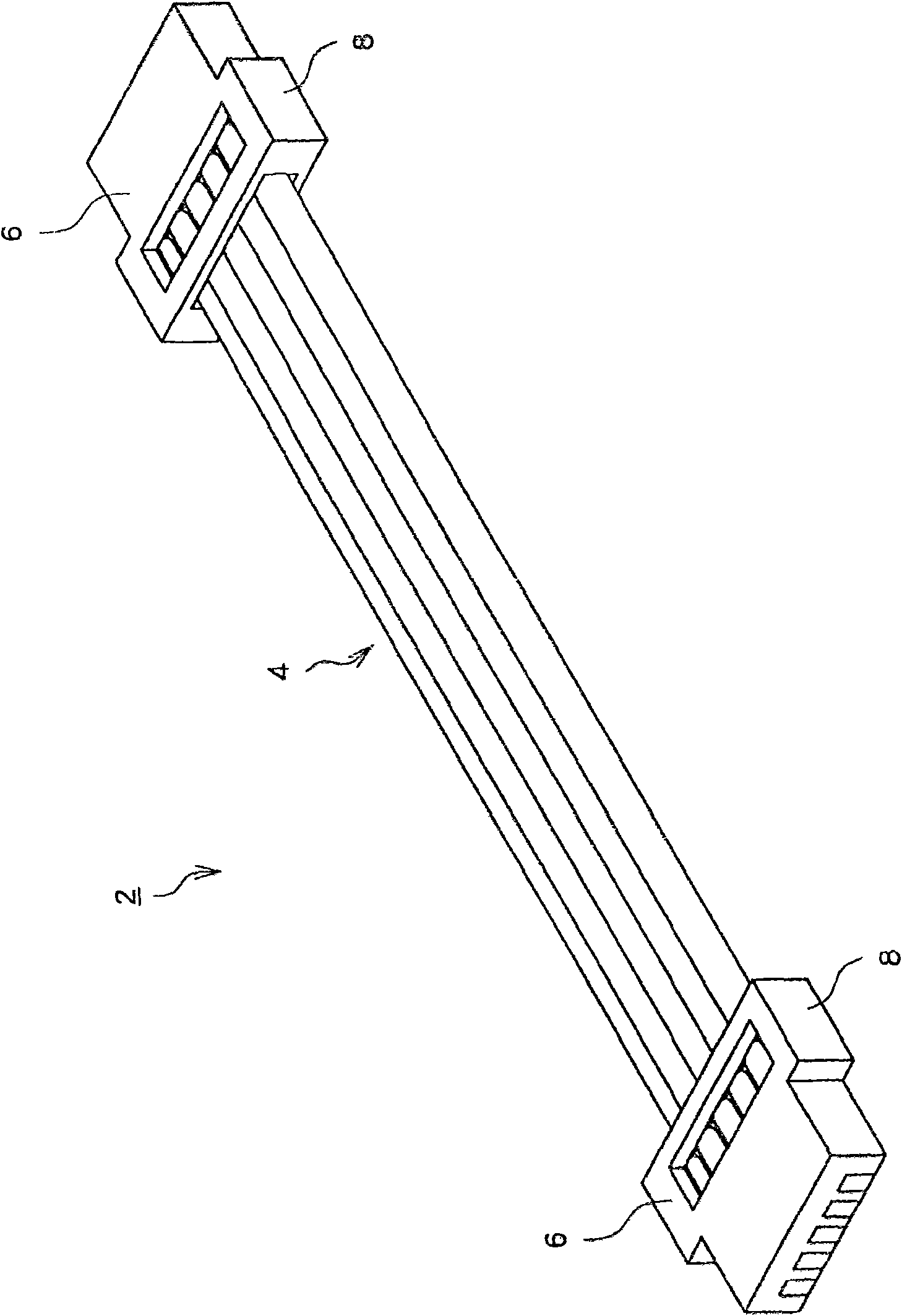

[0020] figure 1 It is a schematic perspective view of the wire harness of embodiment. The wire harness 2 is composed of a cable part 4 and connector parts 6 respectively provided at both ends. The cable unit 4 is, for example, a flat cable composed of a plurality of coaxial cables arranged in parallel. The shape of the connector part 6 is determined by the housing 8, for example, what constitutes a male connector is called a plug housing, and what constitutes a female connector is called a socket housing. E.g, figure 1 The illustrated connector portion 6 is a male connector, and is fitted to a female connector mounted on a board or the like (not shown).

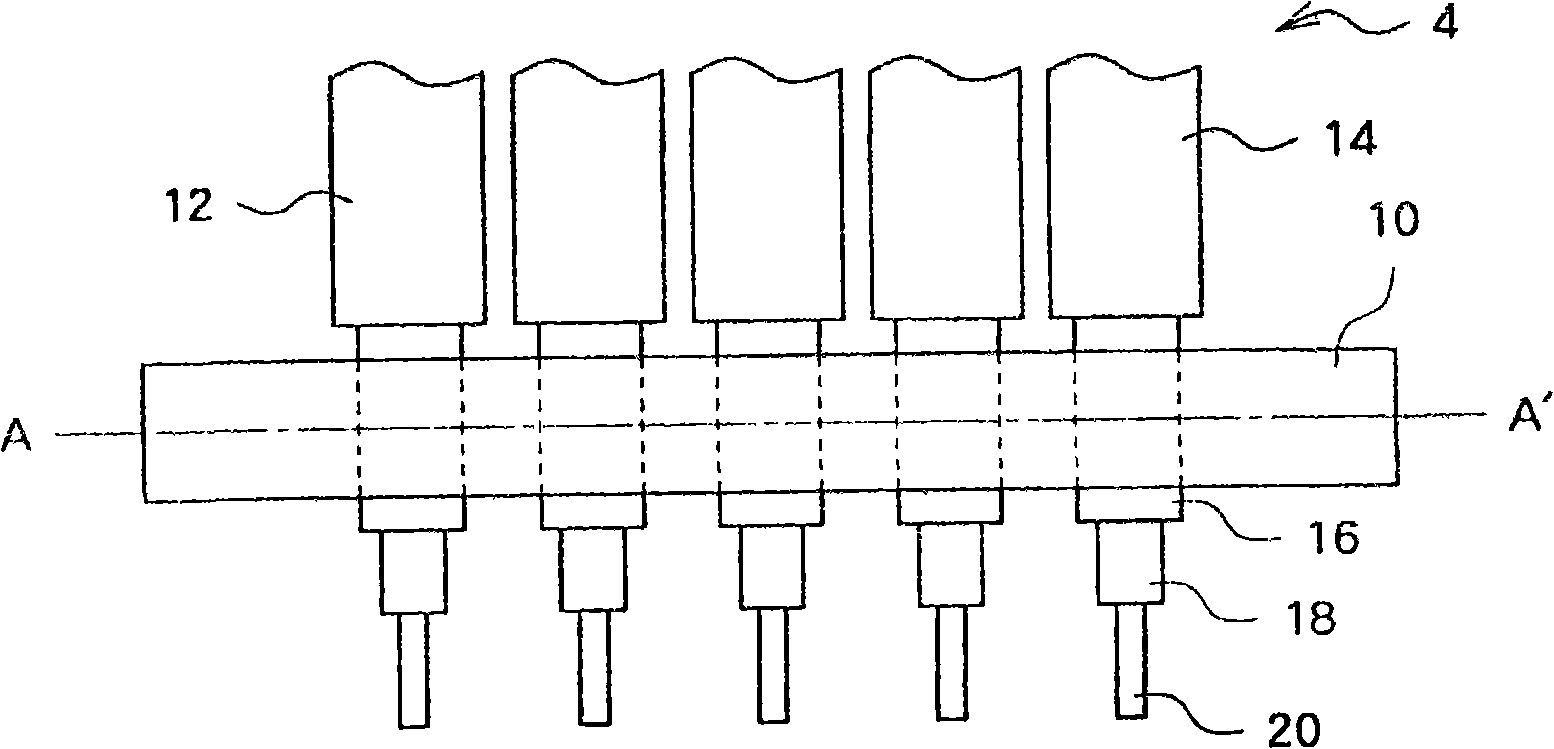

[0021] figure 2 It is a schematic diagram which shows the structure of the connector part 6. The connector part 6 includes a housing 8 , a ground rod 10 , and an end part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com