Raw material preheating part integrated steam reformer and hydrogen production system containing it

A water vapor and reformer technology, which is applied in lighting and heating equipment, steam generation, steam boilers, etc., can solve the problems of rising demand for device miniaturization, high-priced heat-resistant materials, difficult operation, maintenance and management, and achieve improved Equipment compactness rate and effect of reaction improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

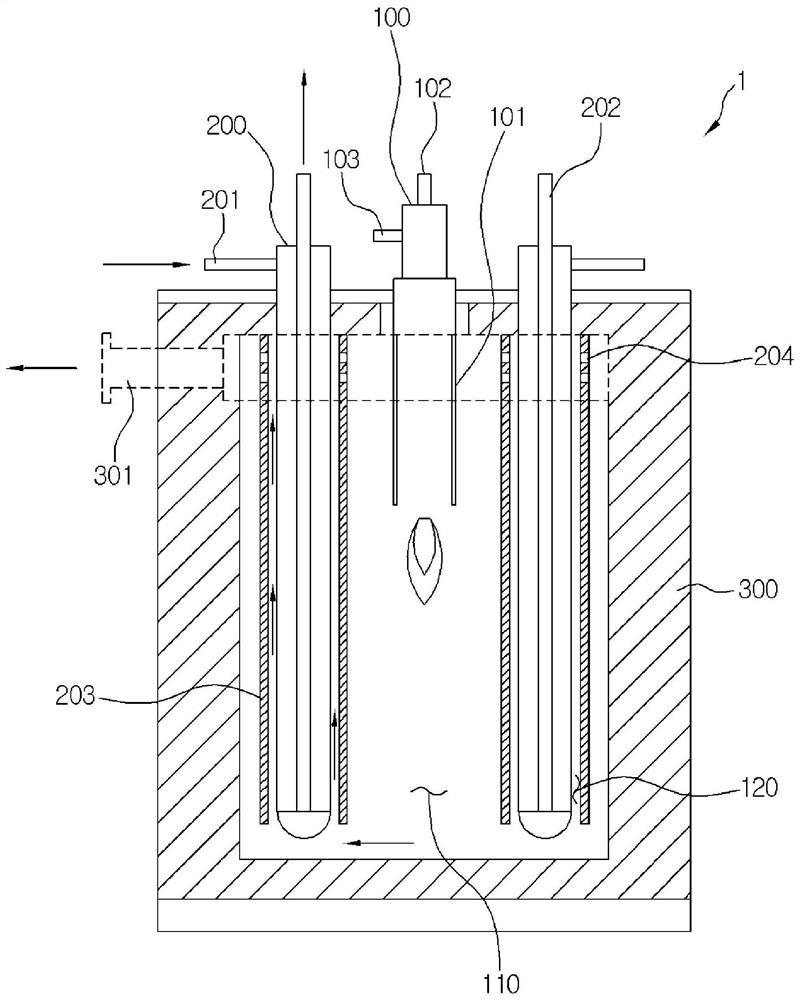

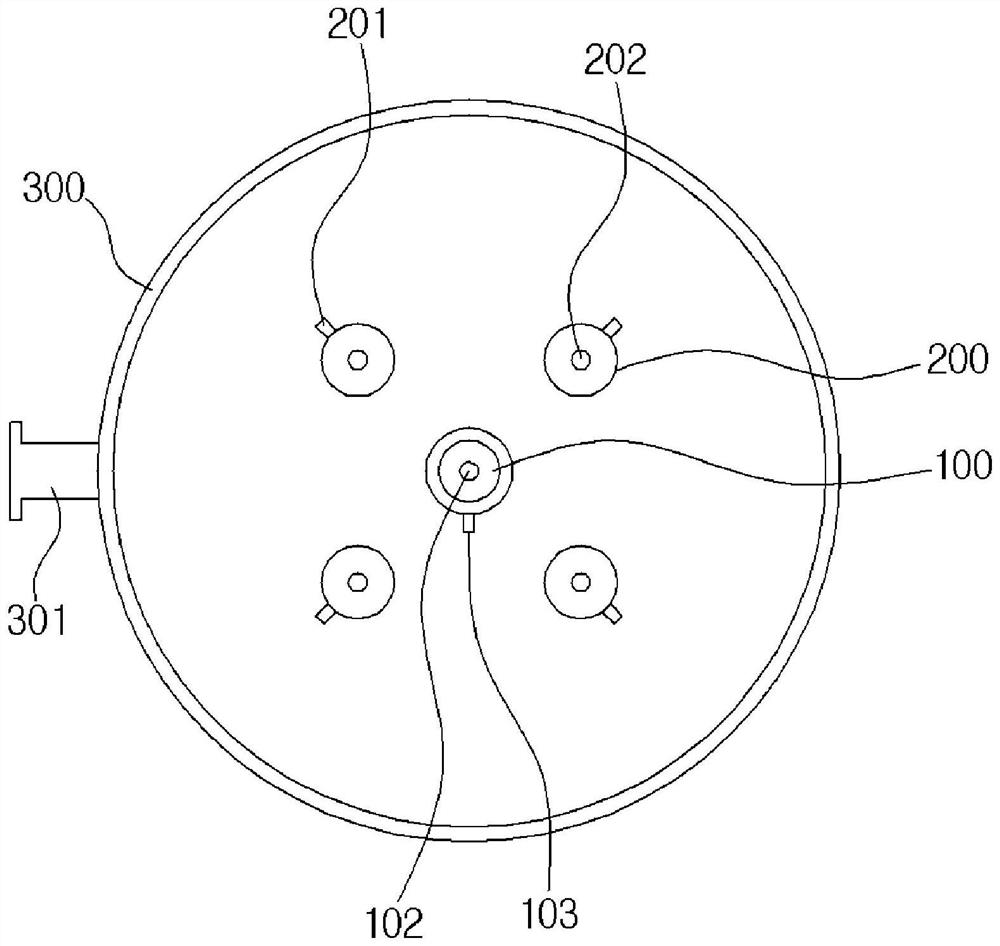

[0102] will be like Figure 4 The distance between the outer surface of the reaction tube 200 and the inner surface of the casing 203 in the shown steam reformer, that is, the heat exchange channel 120 was adjusted to 3 mm, and the reaction operation was carried out according to the operating conditions shown in Table 1. As a result, the composition change and pressure loss of the generated gas are shown in Table 2 below.

Embodiment 2

[0104] Except that the space between the reaction tube 200 outside and the inner surface of the casing 203 in the steam reformer in Example 1, that is, the heat exchange flow path 120 is changed to 5 mm, all the others are implemented in the same way as in Example 1, and the generated The changes in gas composition and pressure loss are shown in Table 2 below.

Embodiment 3

[0106] Except that the distance between the outer surface of the reaction tube 200 in the water vapor reformer and the inner surface of the casing 203 in Example 1, that is, the heat exchange flow path 120 is changed to 7 mm, all the others are implemented in the same way as in Example 1, and the resulting The changes in gas composition and pressure loss are shown in Table 2 below.

[0107] 【Table 2】

[0108]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com