Sputtering device

A sputtering device and substrate technology, applied in the direction of sputtering coating, vacuum evaporation coating, coating, etc., can solve the problems of uneven quality of aluminum film, increase of upper particle size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

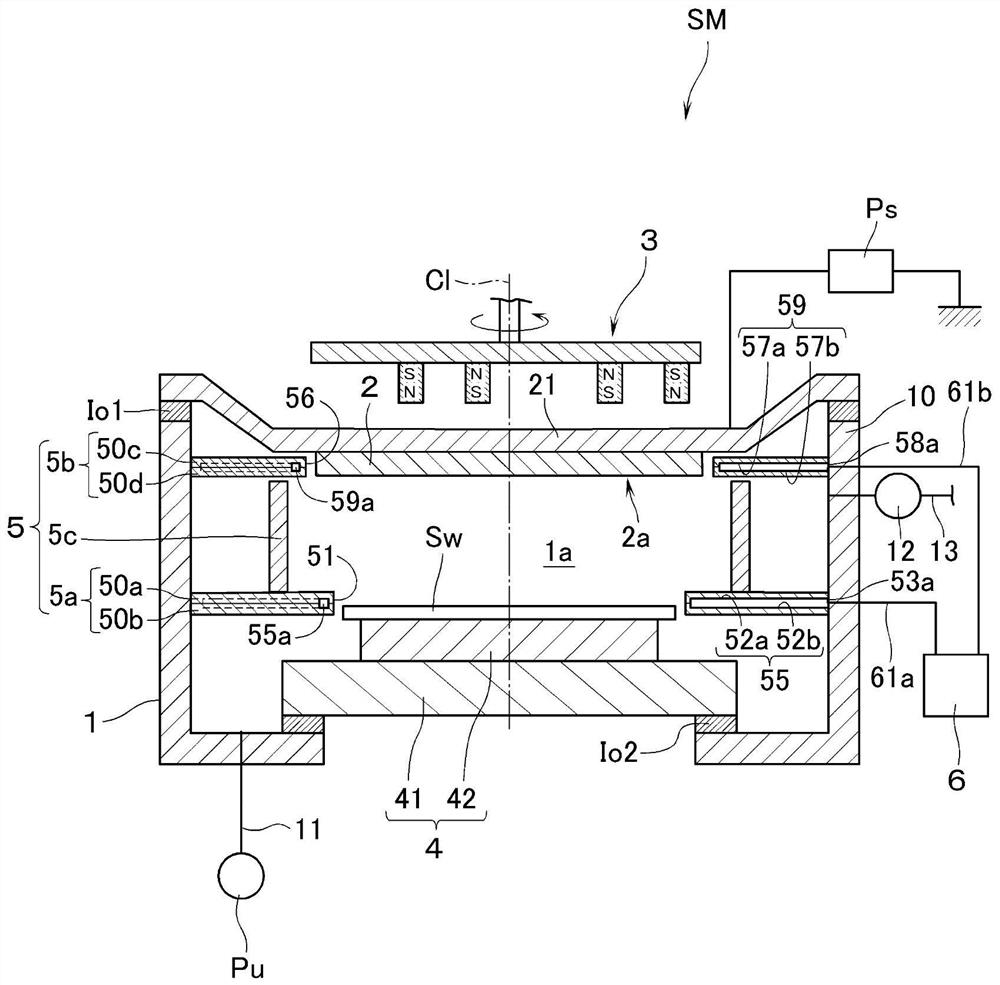

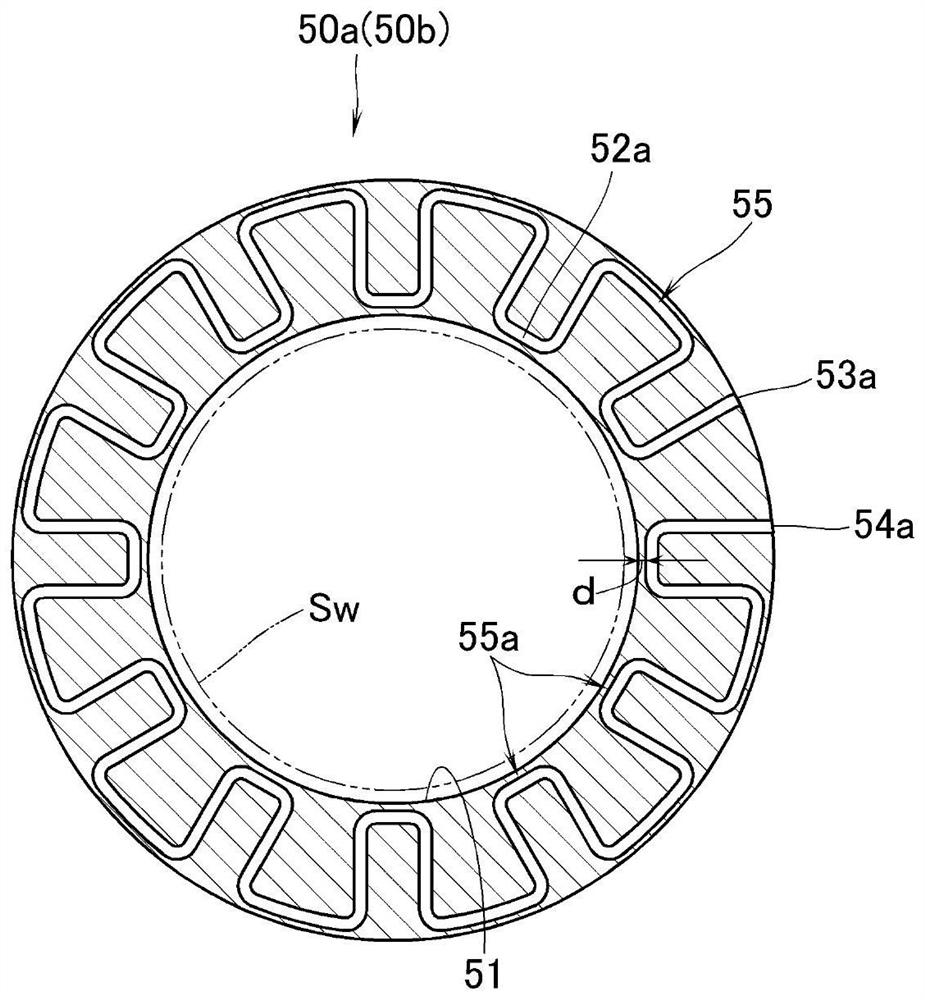

[0017] Referring to the accompanying drawings, an embodiment of the sputtering device of the present invention will be described by taking the case where a silicon wafer (hereinafter referred to as "substrate Sw") having a substantially circular outline is used as a substrate to be processed and an aluminum film is formed on the surface of the substrate Sw as an example. . The following terms denoting such directions as up and down are preceded by figure 1 The shown installation posture of the sputtering apparatus is a reference.

[0018] refer to figure 1 , SM is a sputtering device, and the sputtering device SM has a vacuum chamber 1 . An exhaust pipe 11 is connected to the vacuum chamber 1, and the vacuum in the vacuum chamber 1 is exhausted to a prescribed pressure (such as 1 × 10 -5 Pa), the exhaust pipe 11 shown communicates with a vacuum pump unit Pu composed of a turbomolecular pump or a rotary pump or the like. The side wall 10 of the vacuum chamber 1 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com