Natural gas hydrogen preparation and proton-exchange film fuel cell integrated generation method and device thereof

A proton exchange membrane and fuel cell technology, which is applied in the parts of fuel cells, solid electrolyte fuel cells, fuel cells, etc., can solve the problems of high operating cost and large hydrogen partial pressure difference of palladium membrane, and achieve reasonable energy allocation, The heat of the system is well matched and the effect of improving the amount of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

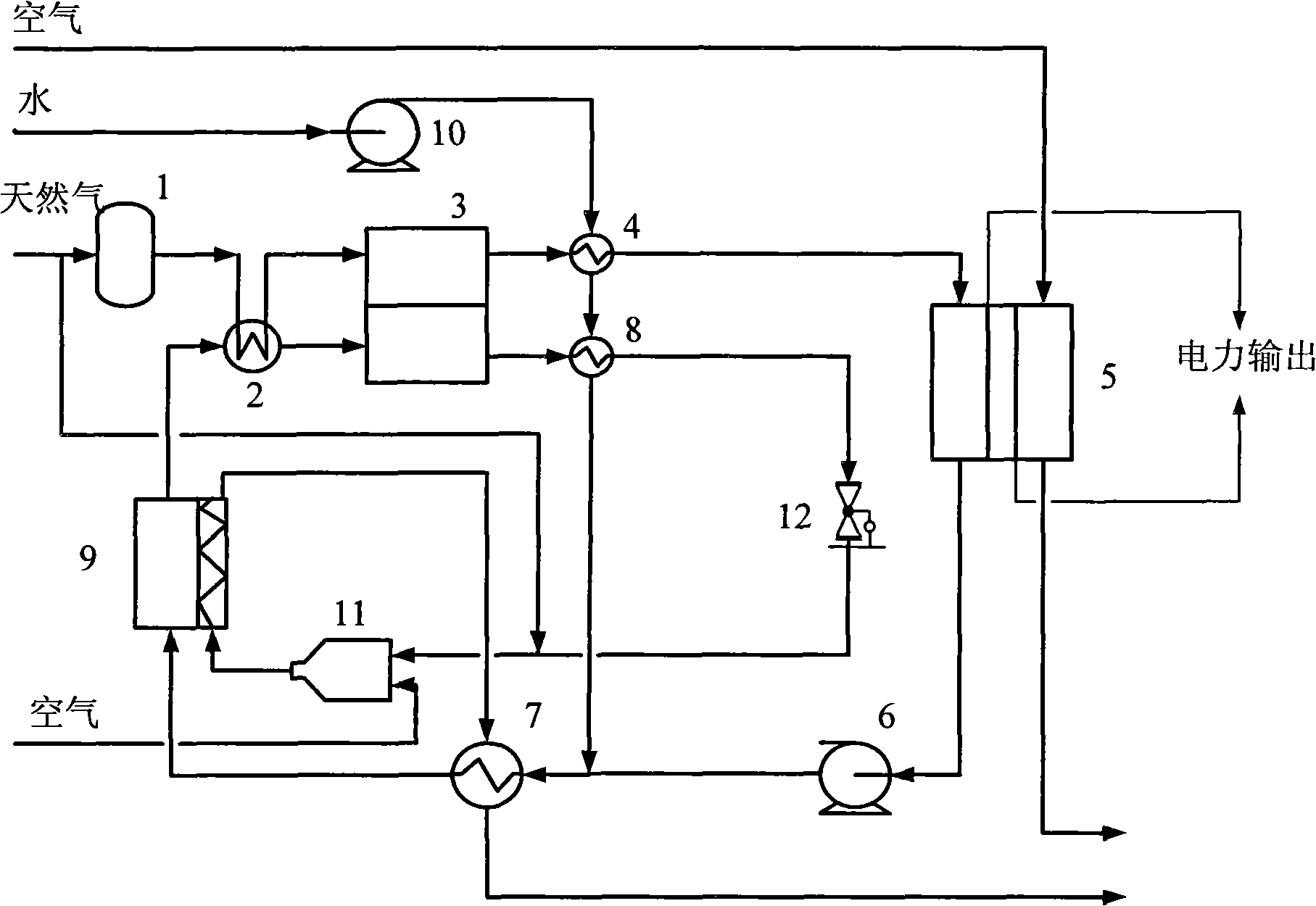

[0025] Example 1: 10 kW level natural gas hydrogen production and proton exchange membrane fuel cell integrated power generation system

[0026] A 10kw natural gas hydrogen production and proton exchange membrane fuel cell integrated power generation system, the system feed is natural gas and desalted water. The natural gas flow rate is 2.49kg / h, and the water flow rate is 10.87kg / h. The molar composition of natural gas is: CH 4 : 96.4%, C 2 h 6 : 1.97%, C 3 h 8 : 0.34%, I-C 4 h 10 : 0.07%, N-C 4 h 10 : 0.08%, N 2 : 0.9%, S: 50ppm, intake pressure: 1.2atm, intake temperature: normal temperature. The inlet water pressure is 1.2atm, and the inlet water temperature is normal temperature.

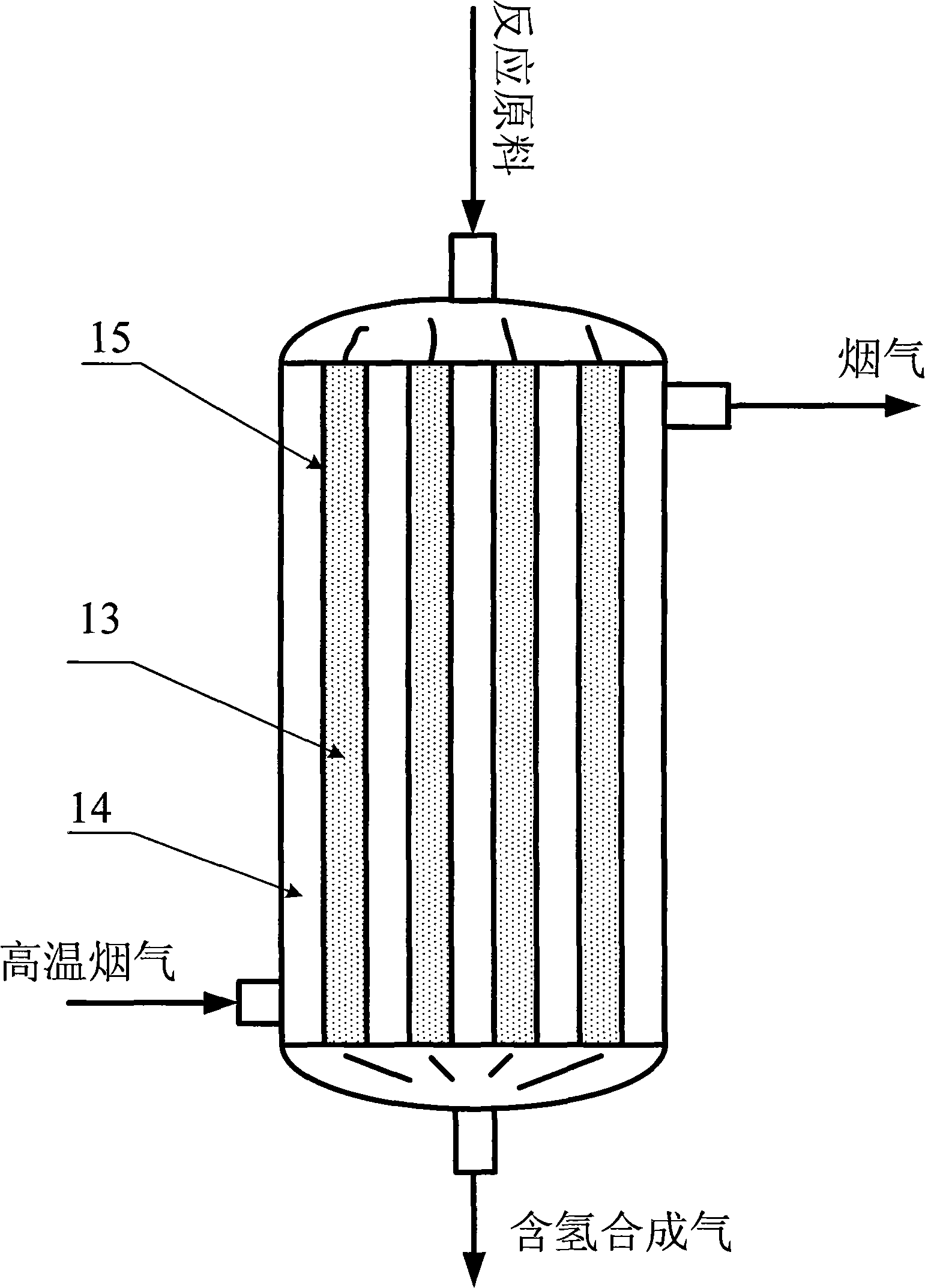

[0027] like figure 1As shown, the 10kw natural gas hydrogen production and proton exchange membrane fuel cell integrated power generation device includes a desulfurizer 1, a first heat exchanger 2, a membrane separator 3, a second heat exchanger 4, a third heat exchanger 7, and a fo...

Embodiment 2

[0037] Example 2: 50 kW level natural gas hydrogen production and proton exchange membrane fuel cell integrated power generation system

[0038] A 50kw natural gas hydrogen production and proton exchange membrane fuel cell integrated power generation system, the feed composition is the same as in Example 1. The feed rate of natural gas is 12kg / h, and the amount of water is 39kg / h. The configuration of the power generation system is the same as in Embodiment 1.

[0039] During operation, raw natural gas is desulfurized by desulfurizer 1 to remove hydrogen sulfide. The desulfurized natural gas enters the first heat exchanger 2 through the pipeline to exchange heat with the hydrogen-containing synthesis gas from the outlet of the reforming reactor 9, the natural gas is heated to 635°C, and the temperature of the synthesis gas is cooled to 640°C. The heat-exchanged natural gas and synthesis gas enter the low-pressure side and high-pressure side of the membrane separator 3 respec...

Embodiment 3

[0042] Example 3: 200 kilowatt-level natural gas hydrogen production and proton exchange membrane fuel cell integrated power generation system

[0043] A 200kw natural gas hydrogen production and proton exchange membrane fuel cell integrated power generation system, the feed composition is the same as in Example 1. The feed rate of natural gas is 46.4kg / h, and the amount of water is 152kg / h. The configuration of the power generation system is the same as in Embodiment 1.

[0044] During operation, raw natural gas is desulfurized by desulfurizer 1 to remove hydrogen sulfide. The desulfurized natural gas enters the first heat exchanger 2 through the pipeline to exchange heat with the hydrogen-containing synthesis gas from the outlet of the reforming reactor 9. The natural gas is heated to 600°C, and the temperature of the synthesis gas is cooled to 610°C. The heat-exchanged natural gas and synthesis gas enter the low-pressure side and high-pressure side of the membrane separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com